Oiling Palm Hammer

Regular applications of oil will extend the useful life of the piston assembly.

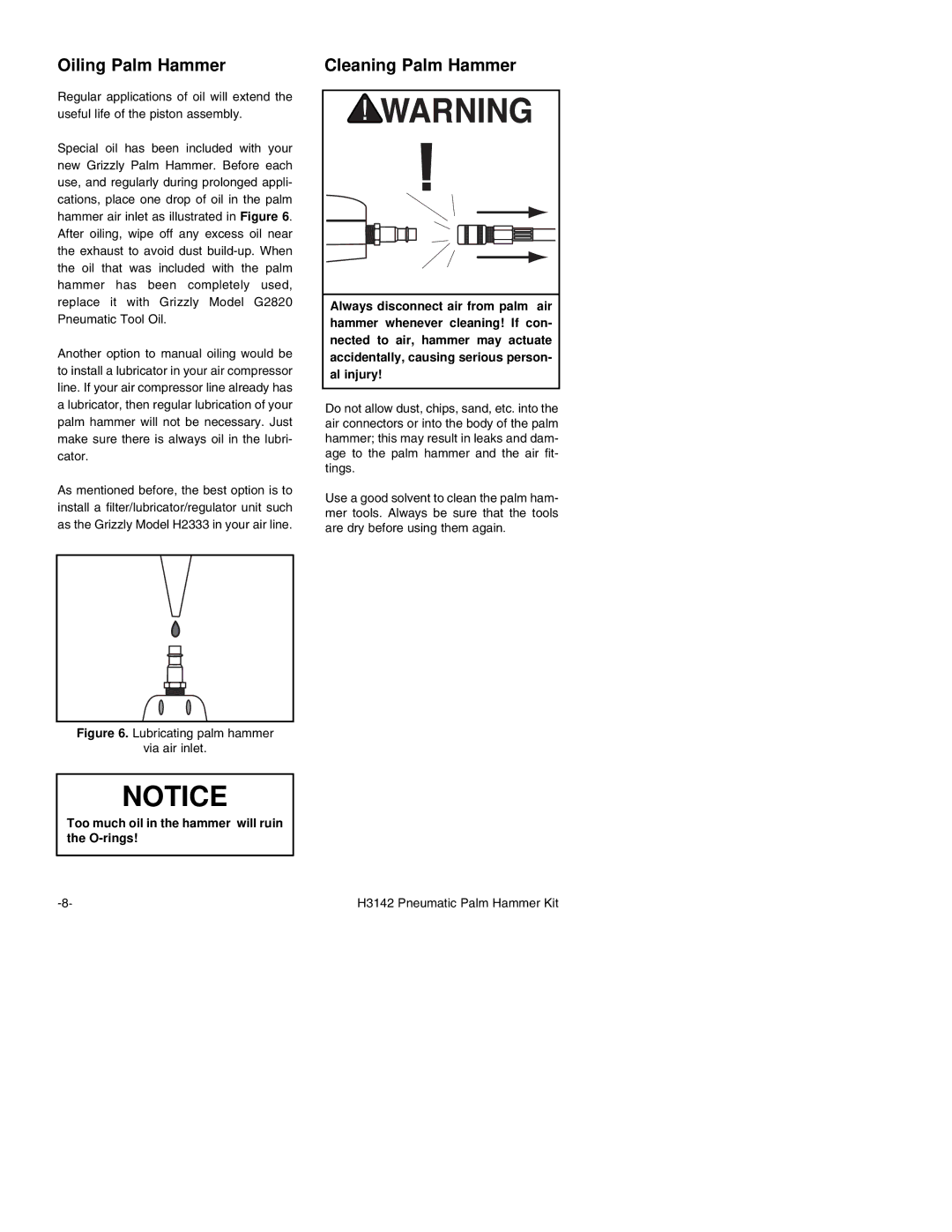

Special oil has been included with your new Grizzly Palm Hammer. Before each use, and regularly during prolonged appli- cations, place one drop of oil in the palm hammer air inlet as illustrated in Figure 6. After oiling, wipe off any excess oil near the exhaust to avoid dust

Another option to manual oiling would be to install a lubricator in your air compressor line. If your air compressor line already has a lubricator, then regular lubrication of your palm hammer will not be necessary. Just make sure there is always oil in the lubri- cator.

As mentioned before, the best option is to install a filter/lubricator/regulator unit such as the Grizzly Model H2333 in your air line.

Figure 6. Lubricating palm hammer

via air inlet.

Cleaning Palm Hammer

Always disconnect air from palm air hammer whenever cleaning! If con- nected to air, hammer may actuate accidentally, causing serious person- al injury!

Do not allow dust, chips, sand, etc. into the air connectors or into the body of the palm hammer; this may result in leaks and dam- age to the palm hammer and the air fit- tings.

Use a good solvent to clean the palm ham- mer tools. Always be sure that the tools are dry before using them again.

NOTICE

Too much oil in the hammer will ruin the

H3142 Pneumatic Palm Hammer Kit |