drops of oil at a time are necessary. Too much oil will collect inside the tool and be blown out during the exhaust cycle. ONLY USE PNEUMATIC TOOL OIL. Do not use detergent oil or additives as these lubricants will cause accelerated wear to the seals in the tool.

Dirt and water in the air supply are major causes of pneumatic tool wear. Use a filter/oiler for better performance and longer life. The filter must have adequate flow capacity for the specific application. Consult the manufacturer’s instructions for proper maintenance of your filter.

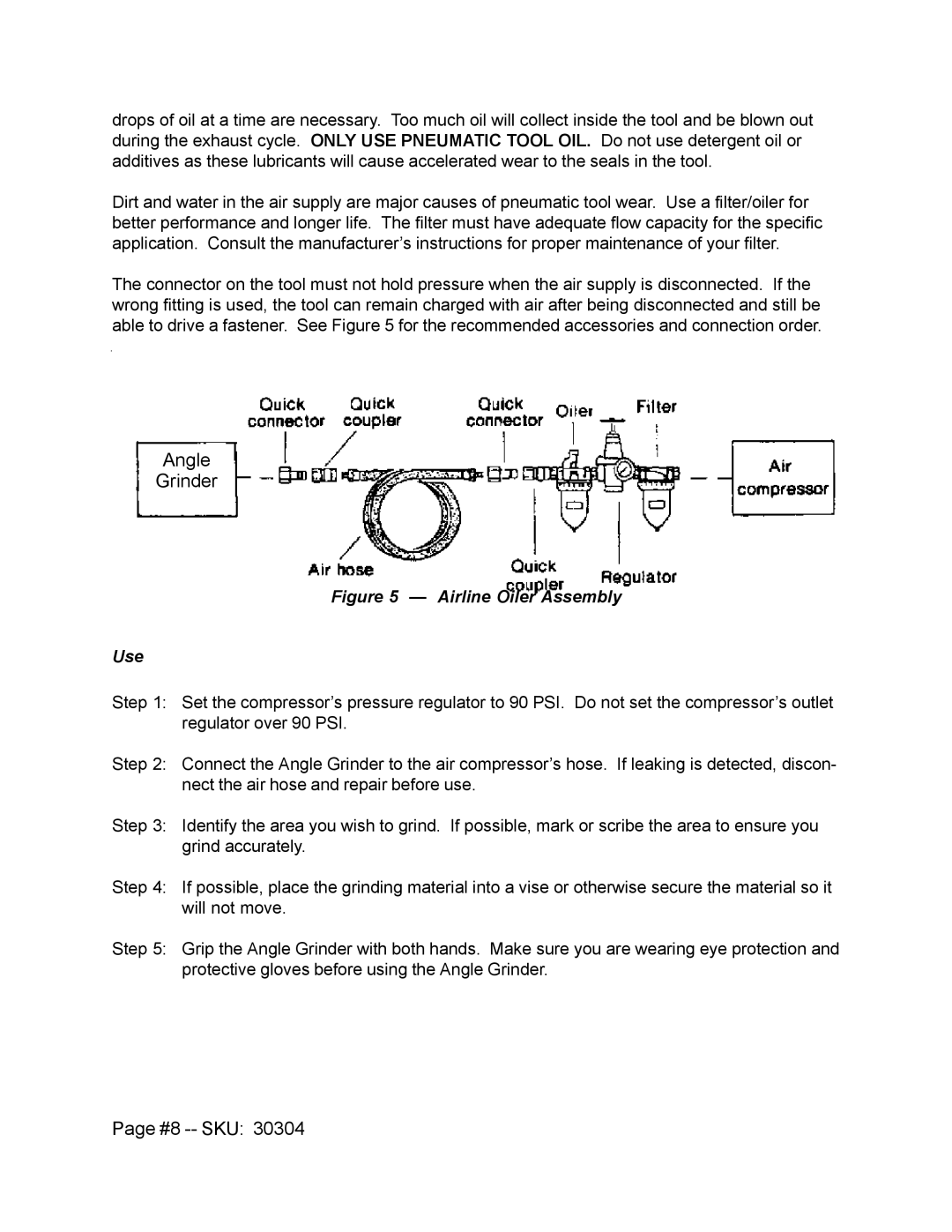

The connector on the tool must not hold pressure when the air supply is disconnected. If the wrong fitting is used, the tool can remain charged with air after being disconnected and still be able to drive a fastener. See Figure 5 for the recommended accessories and connection order.

Angle

Grinder

Figure 5 — Airline Oiler Assembly

Use

Step 1: Set the compressor’s pressure regulator to 90 PSI. Do not set the compressor’s outlet regulator over 90 PSI.

Step 2: Connect the Angle Grinder to the air compressor’s hose. If leaking is detected, discon- nect the air hose and repair before use.

Step 3: Identify the area you wish to grind. If possible, mark or scribe the area to ensure you grind accurately.

Step 4: If possible, place the grinding material into a vise or otherwise secure the material so it will not move.

Step 5: Grip the Angle Grinder with both hands. Make sure you are wearing eye protection and protective gloves before using the Angle Grinder.