Operation

1.Install a standard 1/4” Air Connector (not included) to the Air Inlet (36). First wrap the threaded portion of the 1/4” air connector with pipe thread seal tape before threading it into the Air Inlet (36). Tighten securely.

2.Attach a standard quick connector (not included) to your 3/8” air pressure source hose. Then attach the air hose to the Air Impact Wrench.

NOTE: If you are not using an automatic

3.Set the air pressure regulator on your air compressor at 90 psi.

WARNING: Do not exceed the recommended pressure of 90 psi. Damage to your tool, and possible personal injury and/or property damage may result.

4.Check the air line and its connections for air leaks. Make note of these, and repair them before using this tool.

NOTE: Turn off your air compressor and disconnect the air pressure hose before changing sockets or making any adjustments to this tool. Severe injury or property damage may otherwise result.

WARNING: This tool generates considerable torque when in use. Always hold the tool with both hands when using, and brace yourself to resist the torque which will be delivered to the work piece.

5.Select the appropriate size 3/8” square drive impact socket (not included) for your needs. Push and snap the socket onto the Anvil (9).

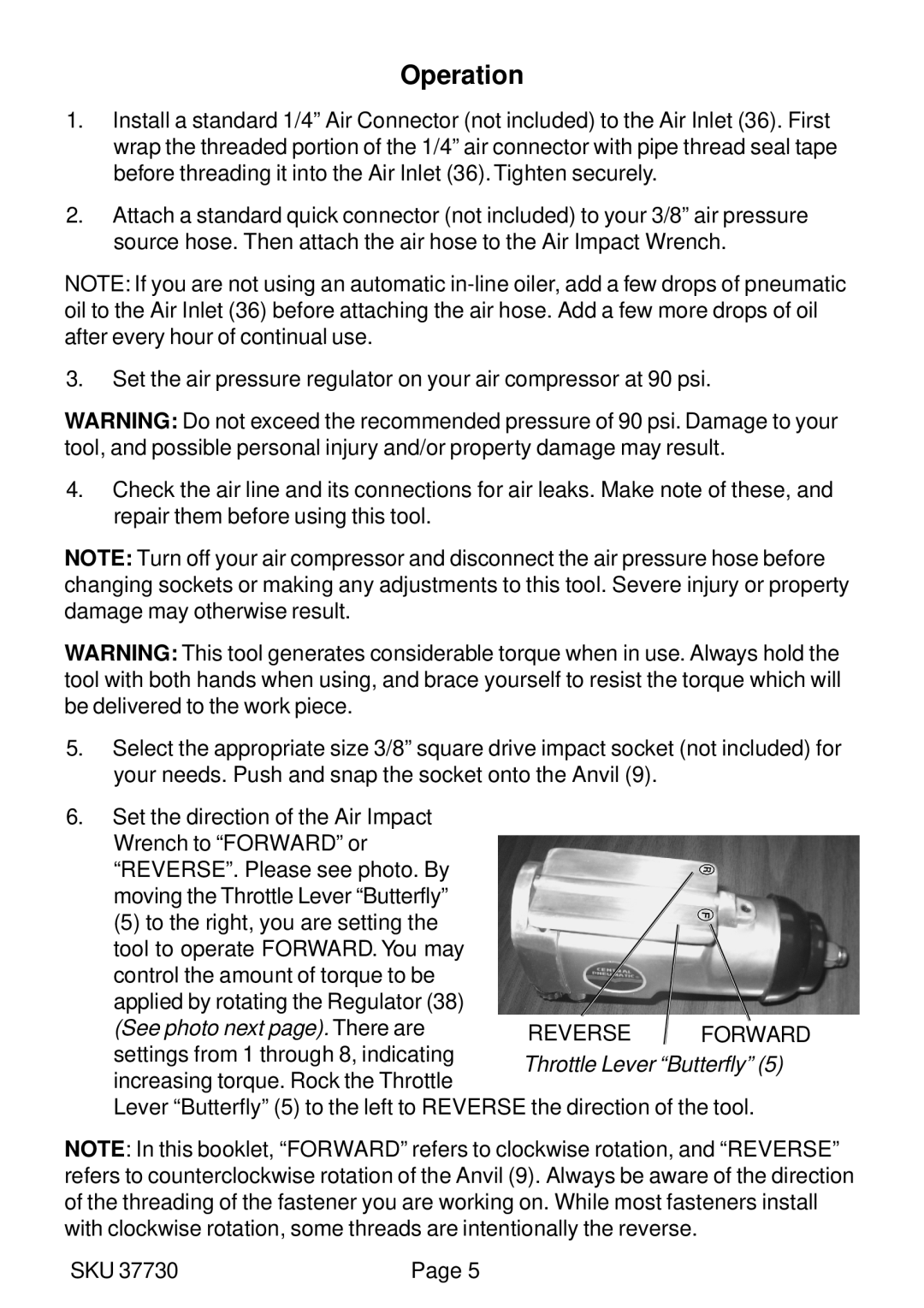

6.Set the direction of the Air Impact Wrench to “FORWARD” or “REVERSE”. Please see photo. By moving the Throttle Lever “Butterfly”

(5) to the right, you are setting the

tool to operate FORWARD. You may control the amount of torque to be applied by rotating the Regulator (38)

(See photo next page). There are REVERSE FORWARD settings from 1 through 8, indicating

increasing torque. Rock the Throttle

Lever “Butterfly” (5) to the left to REVERSE the direction of the tool.

NOTE: In this booklet, “FORWARD” refers to clockwise rotation, and “REVERSE” refers to counterclockwise rotation of the Anvil (9). Always be aware of the direction of the threading of the fastener you are working on. While most fasteners install with clockwise rotation, some threads are intentionally the reverse.

SKU 37730 | Page 5 |