Electrical Installation (continued) Refer to FIGURE 2 on page 5.

Note: Wiring must be done by a professionally certified electrician.

1.Remove the side panel.

2.The top three wires of the electrical box are

3.The wires from the electrical cord (not included) must be rated for a minimum of

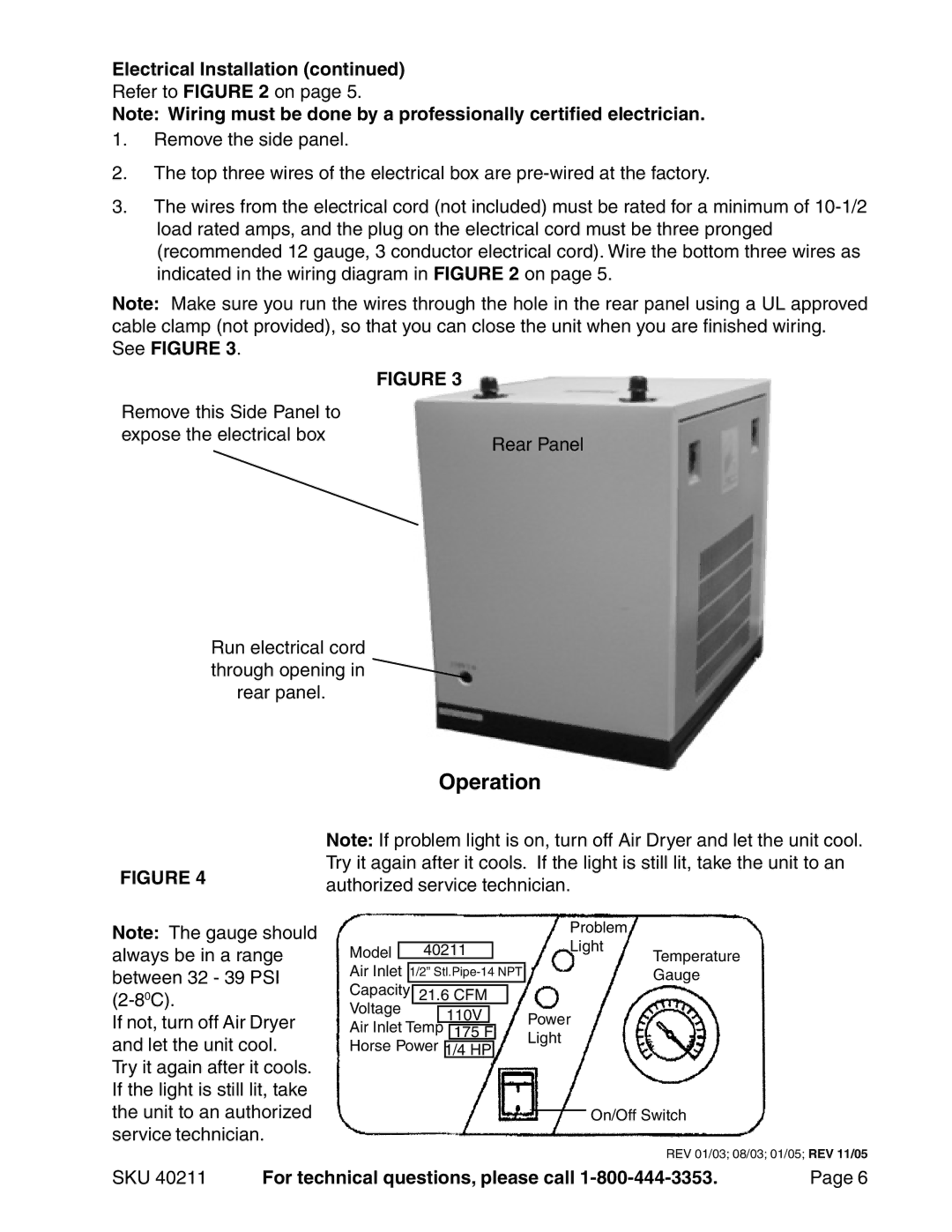

Note: Make sure you run the wires through the hole in the rear panel using a UL approved cable clamp (not provided), so that you can close the unit when you are finished wiring. See FIGURE 3.

FIGURE 3

Remove this Side Panel to

expose the electrical box

Rear Panel

Run electrical cord

through opening in ![]() rear panel.

rear panel.

Operation

FIGURE 4

Note: If problem light is on, turn off Air Dryer and let the unit cool. Try it again after it cools. If the light is still lit, take the unit to an authorized service technician.

Note: The gauge should always be in a range between 32 - 39 PSI

If not, turn off Air Dryer and let the unit cool. Try it again after it cools. If the light is still lit, take

Model 40211

Air Inlet 1/2”

Capacity 21.6 CFM

Voltage 110V

Air Inlet Temp 175 F

Horse Power 1/4 HP

Problem

Light

Power

Light

Temperature Gauge

the unit to an authorized service technician.

On/Off Switch

REV 01/03; 08/03; 01/05; REV 11/05

SKU 40211 | For technical questions, please call | Page 6 |