Grinding with the Flex Shaft |

| Maintenance | |

Wheel Cover (14) | Dressing the Grinding Wheel | ||

Note: New wheels frequently are not | |||

| |||

|

| true and during operation will often | |

|

| become grooved, glazed (build up), | |

|

| out of round, or misshapen. You will | |

(37) |

| need a grinding wheel dresser for | |

|

| this operation. Dressers are available | |

|

| from Harbor Freight Tools. | |

1. Stand to the side of the wheel for this

Flex Shaft (32) | operation. |

|

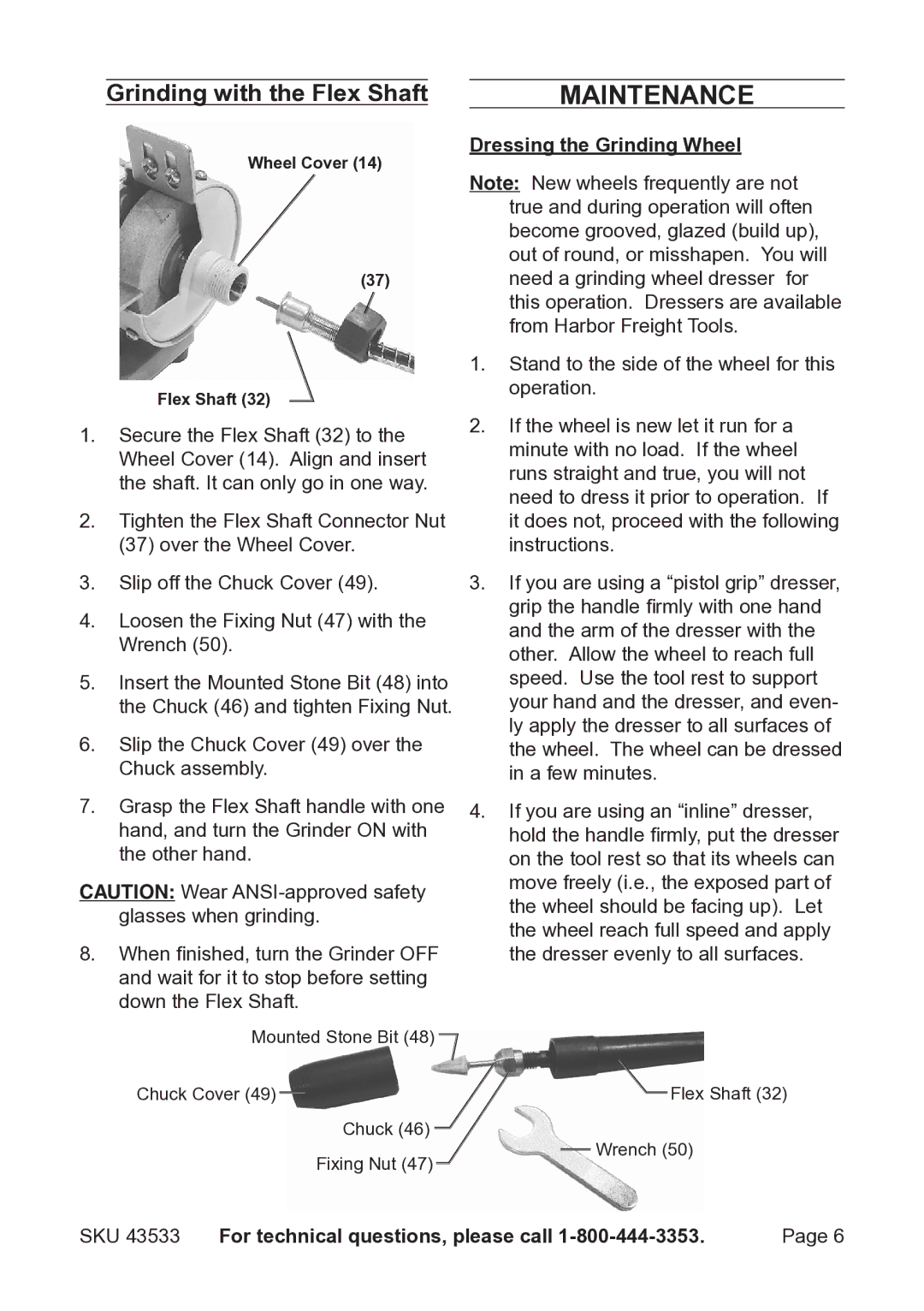

1.Secure the Flex Shaft (32) to the Wheel Cover (14). Align and insert the shaft. It can only go in one way.

2.Tighten the Flex Shaft Connector Nut (37) over the Wheel Cover.

3.Slip off the Chuck Cover (49).

4.Loosen the Fixing Nut (47) with the Wrench (50).

5.Insert the Mounted Stone Bit (48) into the Chuck (46) and tighten Fixing Nut.

6.Slip the Chuck Cover (49) over the Chuck assembly.

7.Grasp the Flex Shaft handle with one hand, and turn the Grinder ON with the other hand.

CAUTION: Wear

8.When finished, turn the Grinder OFF and wait for it to stop before setting down the Flex Shaft.

Mounted Stone Bit (48)![]()

Chuck Cover (49)

Chuck (46)

Fixing Nut (47)

2.If the wheel is new let it run for a minute with no load. If the wheel runs straight and true, you will not need to dress it prior to operation. If it does not, proceed with the following instructions.

3.If you are using a “pistol grip” dresser, grip the handle firmly with one hand and the arm of the dresser with the other. Allow the wheel to reach full speed. Use the tool rest to support your hand and the dresser, and even- ly apply the dresser to all surfaces of the wheel. The wheel can be dressed in a few minutes.

4.If you are using an “inline” dresser, hold the handle firmly, put the dresser on the tool rest so that its wheels can move freely (i.e., the exposed part of the wheel should be facing up). Let the wheel reach full speed and apply the dresser evenly to all surfaces.

![]() Flex Shaft (32)

Flex Shaft (32)

Wrench (50)

SKU 43533 | For technical questions, please call | Page 6 |