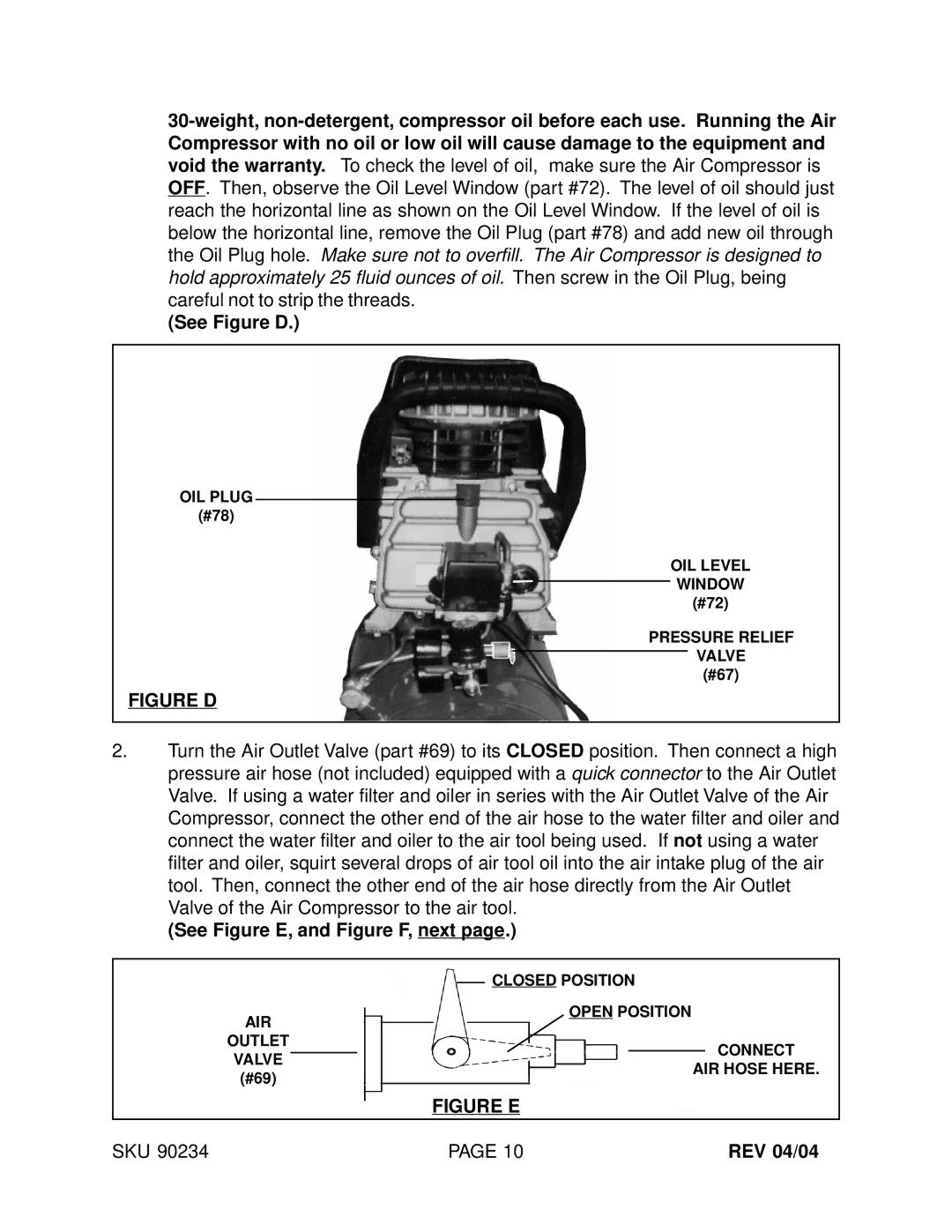

(See Figure D.)

OIL PLUG

(#78)

OIL LEVEL

WINDOW

(#72)

PRESSURE RELIEF

VALVE

(#67)

FIGURE D

2.Turn the Air Outlet Valve (part #69) to its CLOSED position. Then connect a high pressure air hose (not included) equipped with a quick connector to the Air Outlet Valve. If using a water filter and oiler in series with the Air Outlet Valve of the Air Compressor, connect the other end of the air hose to the water filter and oiler and connect the water filter and oiler to the air tool being used. If not using a water filter and oiler, squirt several drops of air tool oil into the air intake plug of the air tool. Then, connect the other end of the air hose directly from the Air Outlet Valve of the Air Compressor to the air tool.

(See Figure E, and Figure F, next page.)

CLOSED POSITION

AIR

OPEN POSITION

OUTLET

VALVE

CONNECT

(#69)

AIR HOSE HERE.

FIGURE E

SKU 90234 | PAGE 10 | REV 04/04 |