IMPORTANT: Improper cleaning is a common reason for the unit not to work properly. Most problems can be avoided or remedied with prompt, thorough cleaning.

Troubleshooting

Spray Pattern Diagnosis

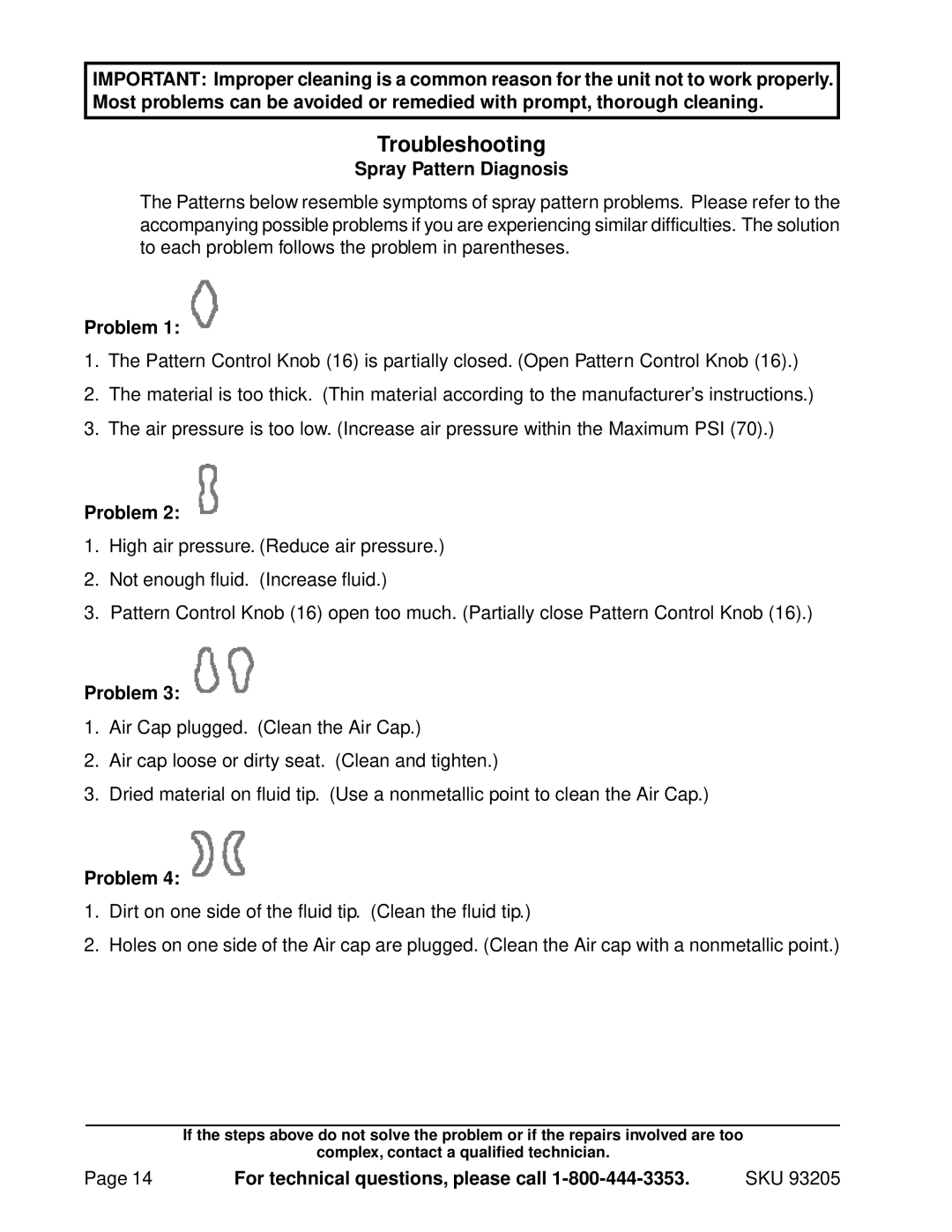

The Patterns below resemble symptoms of spray pattern problems. Please refer to the accompanying possible problems if you are experiencing similar difficulties. The solution to each problem follows the problem in parentheses.

Problem 1:

1.The Pattern Control Knob (16) is partially closed. (Open Pattern Control Knob (16).)

2.The material is too thick. (Thin material according to the manufacturer’s instructions.)

3.The air pressure is too low. (Increase air pressure within the Maximum PSI (70).)

Problem 2:

1.High air pressure. (Reduce air pressure.)

2.Not enough fluid. (Increase fluid.)

3.Pattern Control Knob (16) open too much. (Partially close Pattern Control Knob (16).)

Problem 3:

1.Air Cap plugged. (Clean the Air Cap.)

2.Air cap loose or dirty seat. (Clean and tighten.)

3.Dried material on fluid tip. (Use a nonmetallic point to clean the Air Cap.)

Problem 4:

1.Dirt on one side of the fluid tip. (Clean the fluid tip.)

2.Holes on one side of the Air cap are plugged. (Clean the Air cap with a nonmetallic point.)

If the steps above do not solve the problem or if the repairs involved are too

complex, contact a qualified technician.

Page 14 | For technical questions, please call | SKU 93205 |