IMPORTANT: The Spray Gun must be cleaned immediately after use. Improper cleaning is a common reason for the Spray Gun not to work.

Fan Direction and Pattern Adjustment (continued)

3.Turn the Fluid Control Knob (13A) clockwise until it is fully closed. See FIG 1 on page 6.

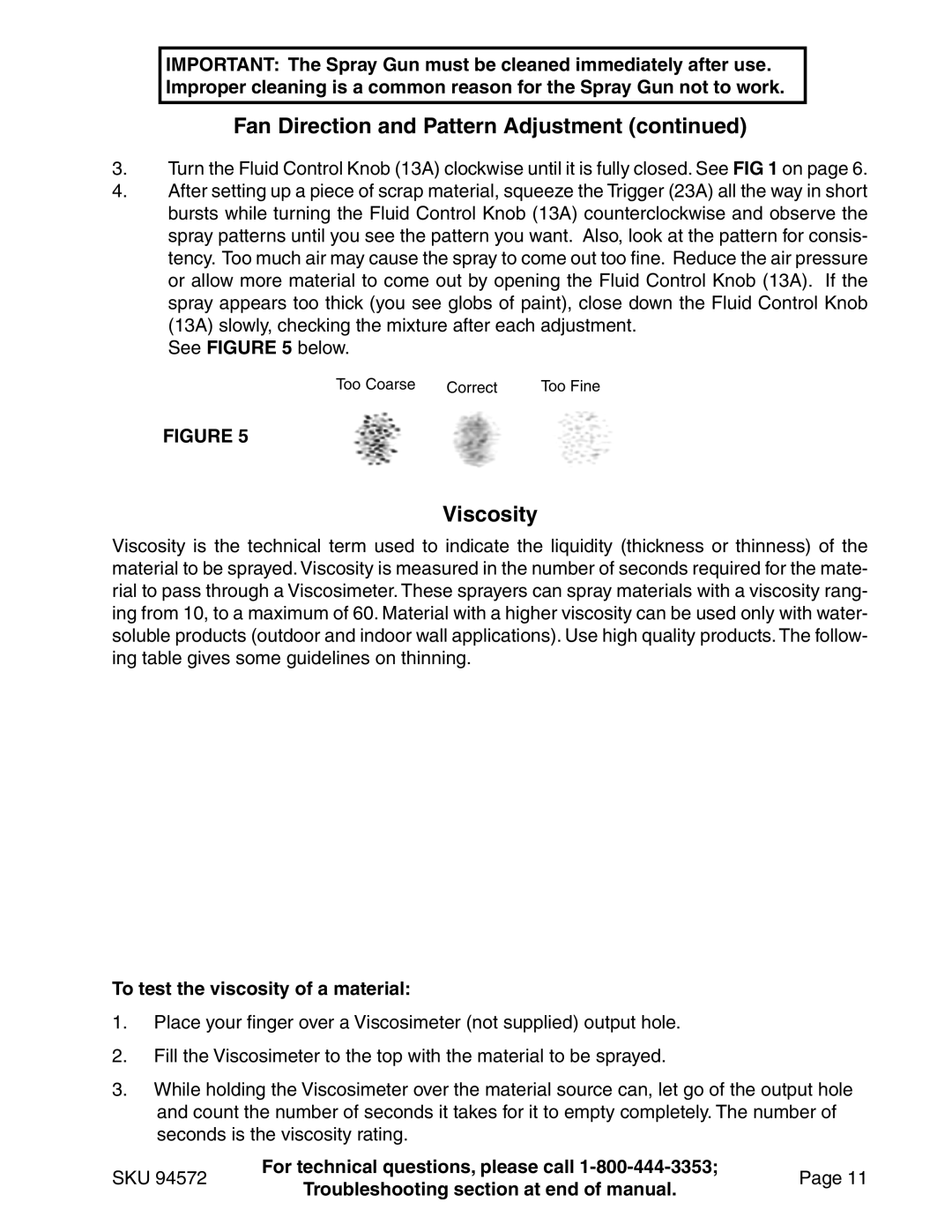

4.After setting up a piece of scrap material, squeeze the Trigger (23A) all the way in short bursts while turning the Fluid Control Knob (13A) counterclockwise and observe the spray patterns until you see the pattern you want. Also, look at the pattern for consis- tency. Too much air may cause the spray to come out too fine. Reduce the air pressure or allow more material to come out by opening the Fluid Control Knob (13A). If the spray appears too thick (you see globs of paint), close down the Fluid Control Knob (13A) slowly, checking the mixture after each adjustment.

See FIGURE 5 below.

Too Coarse | Correct | Too Fine |

FIGURE 5

Viscosity

Viscosity is the technical term used to indicate the liquidity (thickness or thinness) of the material to be sprayed. Viscosity is measured in the number of seconds required for the mate- rial to pass through a Viscosimeter. These sprayers can spray materials with a viscosity rang- ing from 10, to a maximum of 60. Material with a higher viscosity can be used only with water- soluble products (outdoor and indoor wall applications). Use high quality products. The follow- ing table gives some guidelines on thinning.

To test the viscosity of a material:

1.Place your finger over a Viscosimeter (not supplied) output hole.

2.Fill the Viscosimeter to the top with the material to be sprayed.

3.While holding the Viscosimeter over the material source can, let go of the output hole and count the number of seconds it takes for it to empty completely. The number of seconds is the viscosity rating.

SKU 94572 | For technical questions, please call | Page 11 | |

Troubleshooting section at end of manual. | |||

|

|