clean and wipe down Airbrush and all that were used during operation.

3.AFTER EVERY 500 HOURS OF REGULAR USE, replace Compression

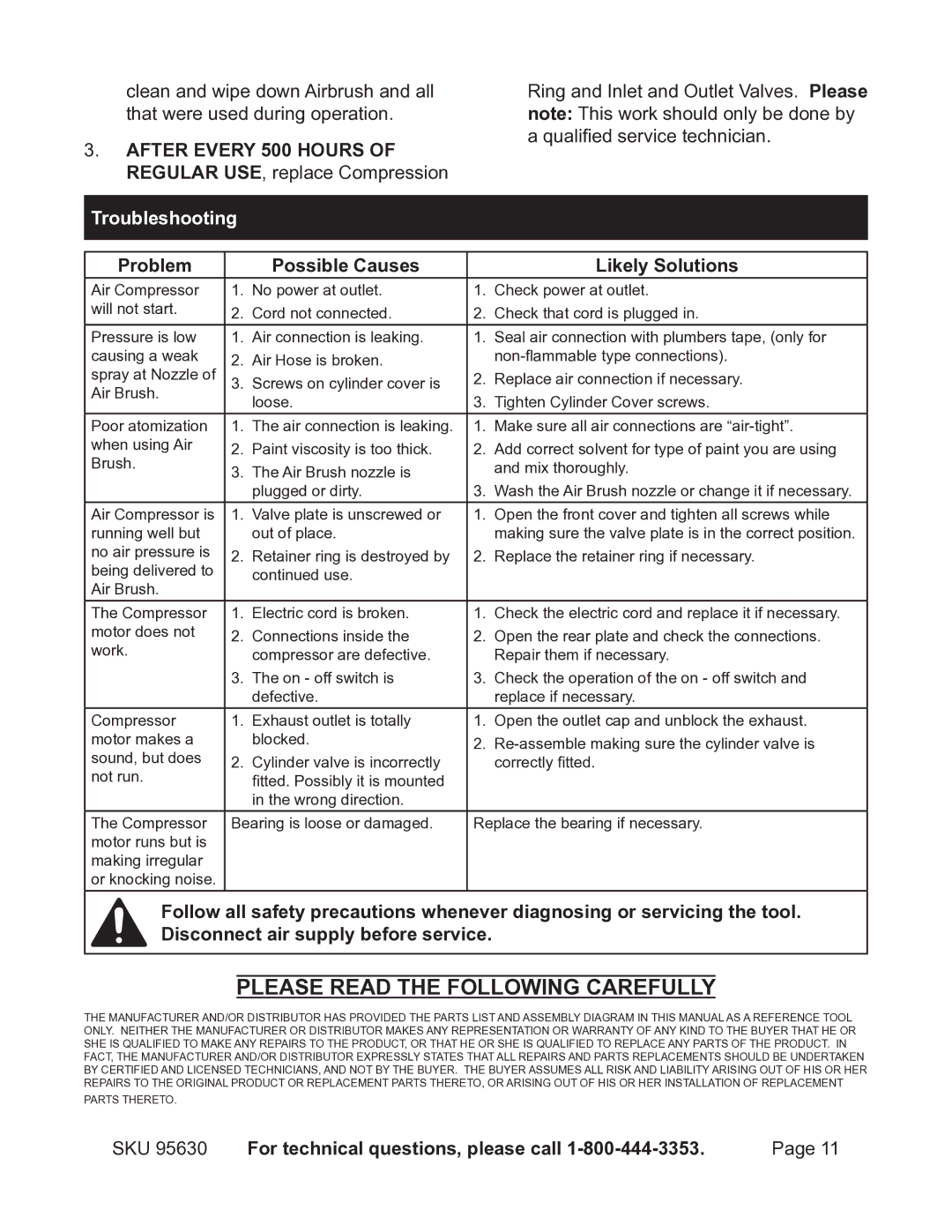

Troubleshooting

Ring and Inlet and Outlet Valves. Please note: This work should only be done by a qualified service technician.

Problem |

| Possible Causes |

| Likely Solutions |

Air Compressor | 1. | No power at outlet. | 1. | Check power at outlet. |

will not start. | 2. | Cord not connected. | 2. | Check that cord is plugged in. |

Pressure is low | 1. | Air connection is leaking. | 1. | Seal air connection with plumbers tape, (only for |

causing a weak | 2. | Air Hose is broken. |

| |

spray at Nozzle of | 3. | Screws on cylinder cover is | 2. | Replace air connection if necessary. |

Air Brush. |

| loose. | 3. | Tighten Cylinder Cover screws. |

|

| |||

Poor atomization | 1. | The air connection is leaking. | 1. | Make sure all air connections are |

when using Air | 2. | Paint viscosity is too thick. | 2. | Add correct solvent for type of paint you are using |

Brush. | 3. | The Air Brush nozzle is |

| and mix thoroughly. |

|

| plugged or dirty. | 3. | Wash the Air Brush nozzle or change it if necessary. |

Air Compressor is | 1. | Valve plate is unscrewed or | 1. | Open the front cover and tighten all screws while |

running well but |

| out of place. |

| making sure the valve plate is in the correct position. |

no air pressure is | 2. | Retainer ring is destroyed by | 2. | Replace the retainer ring if necessary. |

being delivered to |

| continued use. |

|

|

Air Brush. |

|

|

|

|

The Compressor | 1. | Electric cord is broken. | 1. | Check the electric cord and replace it if necessary. |

motor does not | 2. | Connections inside the | 2. | Open the rear plate and check the connections. |

work. |

| compressor are defective. |

| Repair them if necessary. |

| 3. | The on - off switch is | 3. | Check the operation of the on - off switch and |

|

| defective. |

| replace if necessary. |

Compressor | 1. | Exhaust outlet is totally | 1. | Open the outlet cap and unblock the exhaust. |

motor makes a |

| blocked. | 2. | |

sound, but does | 2. | Cylinder valve is incorrectly |

| correctly fitted. |

not run. |

| fitted. Possibly it is mounted |

|

|

|

| in the wrong direction. |

|

|

The Compressor | Bearing is loose or damaged. | Replace the bearing if necessary. | ||

motor runs but is |

|

|

|

|

making irregular |

|

|

|

|

or knocking noise. |

|

|

|

|

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect air supply before service.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT

PARTS THERETO.

SKU 95630 | For technical questions, please call | Page 11 |