structure, as in walls or ceilings, without an approved method for eliminating the hazard. Do not dispose of hot slag in containers holding combustible materials. Keep a fire extinguisher nearby and know how to use it. After welding or cutting, make a thorough examination for evidence of fire. Be aware that easily visible smoke or flame may not be present for some time after the fire has started. Do not weld or cut in atmospheres containing dangerously reactive or flammable gases, vapors, liquids, and dust. Provide adequate ventilation in work areas to prevent accumulation of flammable gases, vapors, and dust. Do not apply heat to a container that has held an unknown substance or a combustible material whose contents, when heated, can produce flammable or explosive vapors. Clean and purge containers before applying heat. Vent closed containers, including castings, before preheating, welding, or cutting.

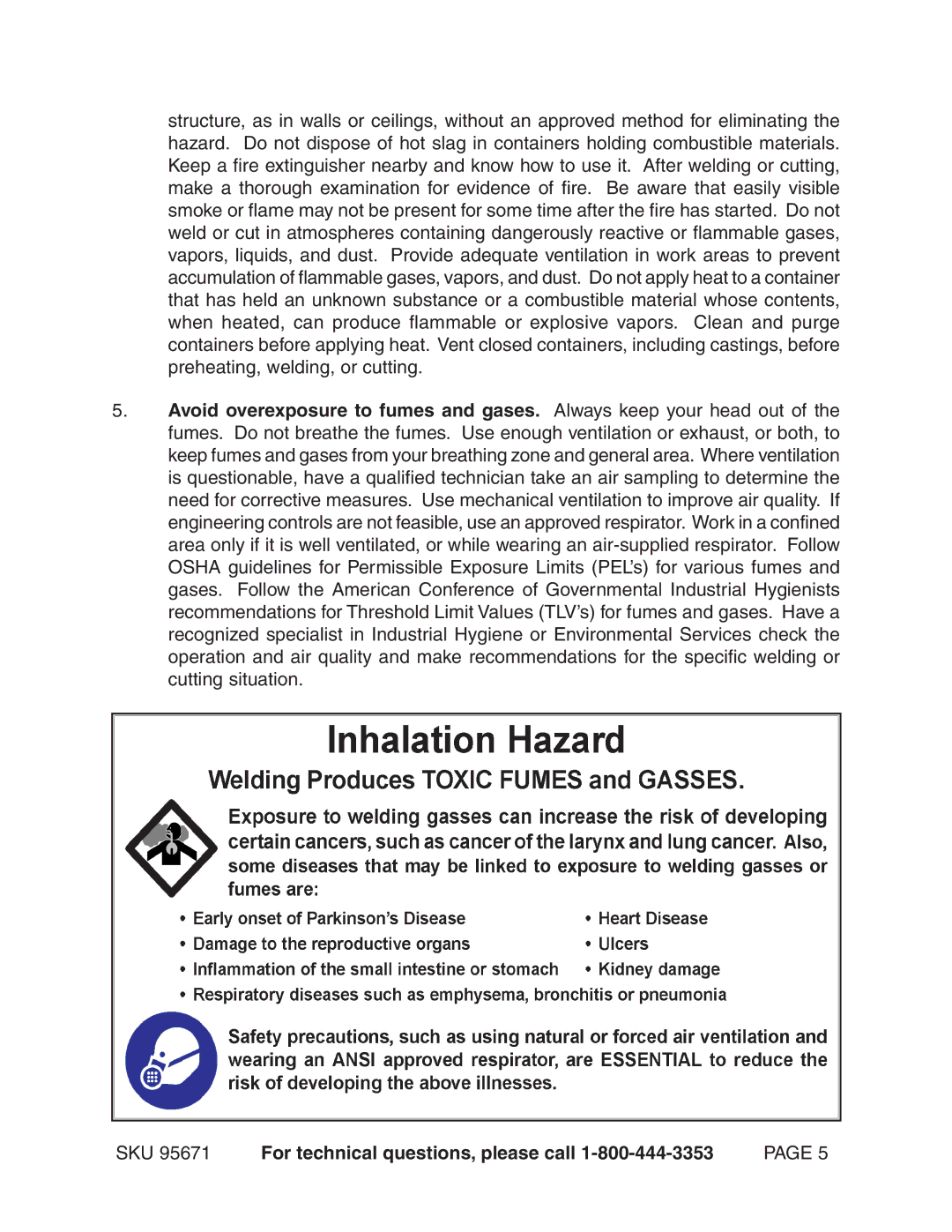

5.Avoid overexposure to fumes and gases. Always keep your head out of the fumes. Do not breathe the fumes. Use enough ventilation or exhaust, or both, to keep fumes and gases from your breathing zone and general area. Where ventilation is questionable, have a qualified technician take an air sampling to determine the need for corrective measures. Use mechanical ventilation to improve air quality. If engineering controls are not feasible, use an approved respirator. Work in a confined area only if it is well ventilated, or while wearing an

SKU 95671 | For technical questions, please call | PAGE 5 |