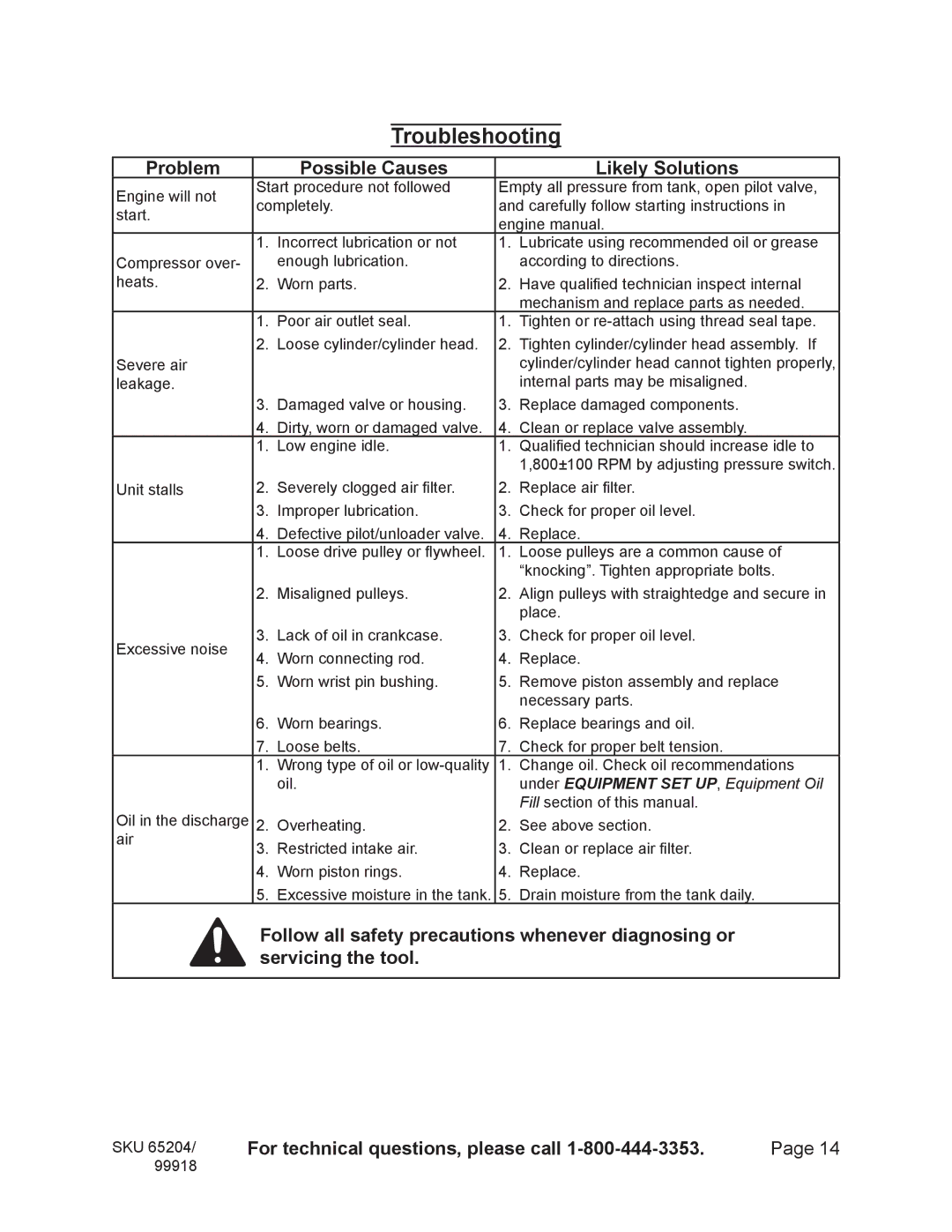

Troubleshooting

Problem |

| Possible Causes |

| Likely Solutions | |

Engine will not | Start procedure not followed | Empty all pressure from tank, open pilot valve, | |||

completely. | and carefully follow starting instructions in | ||||

start. | |||||

|

| engine manual. | |||

|

|

| |||

| 1. | Incorrect lubrication or not | 1. | Lubricate using recommended oil or grease | |

Compressor over- |

| enough lubrication. |

| according to directions. | |

heats. | 2. | Worn parts. | 2. | Have qualified technician inspect internal | |

|

|

|

| mechanism and replace parts as needed. | |

| 1. | Poor air outlet seal. | 1. | Tighten or | |

| 2. | Loose cylinder/cylinder head. | 2. | Tighten cylinder/cylinder head assembly. If | |

Severe air |

|

|

| cylinder/cylinder head cannot tighten properly, | |

leakage. |

|

|

| internal parts may be misaligned. | |

| 3. | Damaged valve or housing. | 3. | Replace damaged components. | |

| 4. | Dirty, worn or damaged valve. | 4. | Clean or replace valve assembly. | |

| 1. | Low engine idle. | 1. | Qualified technician should increase idle to | |

|

|

|

| 1,800±100 RPM by adjusting pressure switch. | |

Unit stalls | 2. | Severely clogged air filter. | 2. | Replace air filter. | |

| 3. | Improper lubrication. | 3. | Check for proper oil level. | |

| 4. | Defective pilot/unloader valve. | 4. | Replace. | |

| 1. | Loose drive pulley or flywheel. | 1. | Loose pulleys are a common cause of | |

|

|

|

| “knocking”. Tighten appropriate bolts. | |

| 2. | Misaligned pulleys. | 2. | Align pulleys with straightedge and secure in | |

|

|

|

| place. | |

Excessive noise | 3. | Lack of oil in crankcase. | 3. | Check for proper oil level. | |

4. | Worn connecting rod. | 4. | Replace. | ||

| |||||

| 5. | Worn wrist pin bushing. | 5. | Remove piston assembly and replace | |

|

|

|

| necessary parts. | |

| 6. | Worn bearings. | 6. | Replace bearings and oil. | |

| 7. | Loose belts. | 7. | Check for proper belt tension. | |

| 1. | Wrong type of oil or | 1. | Change oil. Check oil recommendations | |

|

| oil. |

| under Equipment Set Up, Equipment Oil | |

Oil in the discharge |

|

|

| Fill section of this manual. | |

2. | Overheating. | 2. | See above section. | ||

air | 3. | Restricted intake air. | 3. | Clean or replace air filter. | |

| |||||

| 4. | Worn piston rings. | 4. | Replace. | |

| 5. | Excessive moisture in the tank. | 5. | Drain moisture from the tank daily. | |

Follow all safety precautions whenever diagnosing or servicing the tool.

SKU 65204/ 99918

For technical questions, please call | Page 14 |