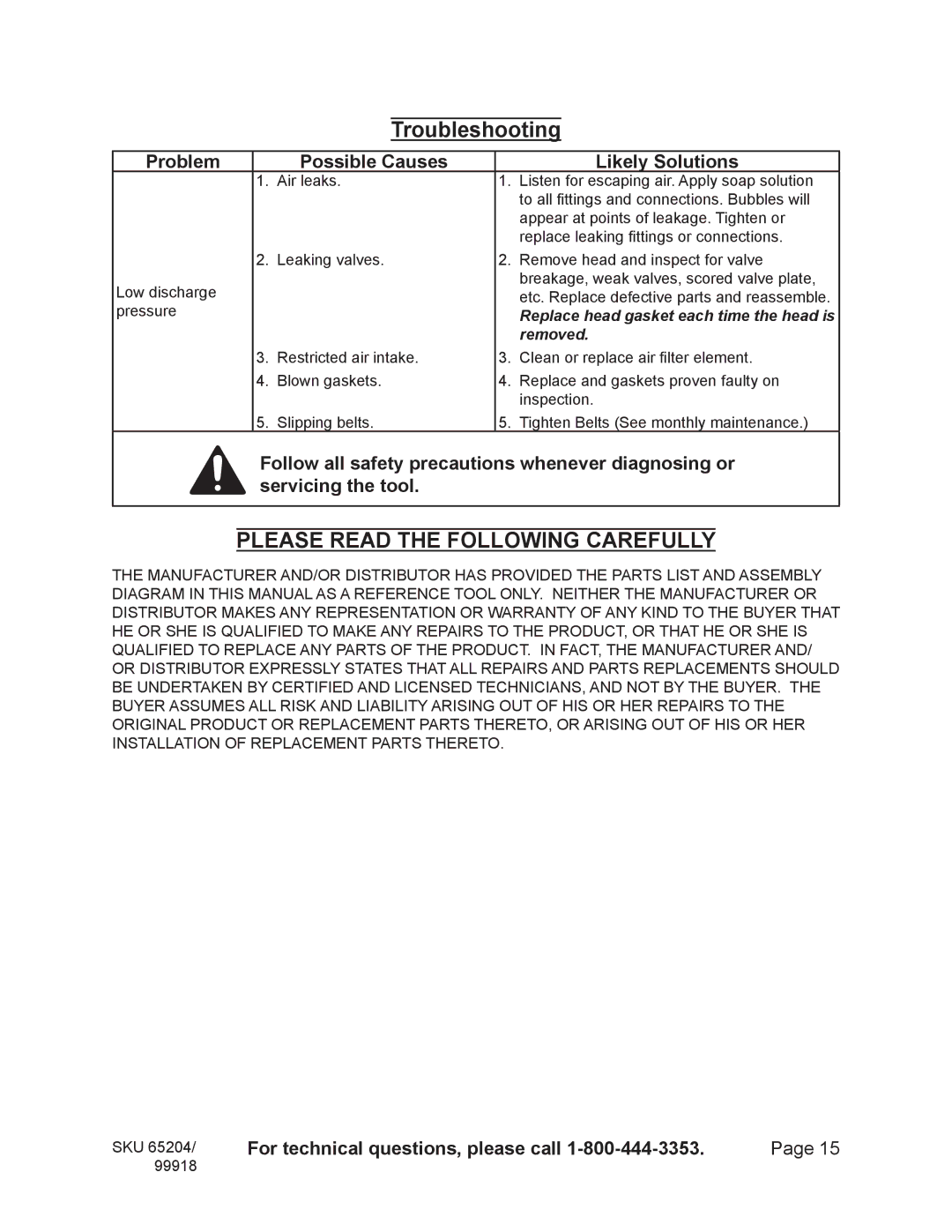

Troubleshooting

Problem |

| Possible Causes |

| Likely Solutions |

| 1. | Air leaks. | 1. | Listen for escaping air. Apply soap solution |

|

|

|

| to all fittings and connections. Bubbles will |

|

|

|

| appear at points of leakage. Tighten or |

|

|

|

| replace leaking fittings or connections. |

| 2. | Leaking valves. | 2. | Remove head and inspect for valve |

Low discharge |

|

|

| breakage, weak valves, scored valve plate, |

|

|

| etc. Replace defective parts and reassemble. | |

pressure |

|

|

| Replace head gasket each time the head is |

|

|

|

| removed. |

| 3. | Restricted air intake. | 3. | Clean or replace air filter element. |

| 4. | Blown gaskets. | 4. | Replace and gaskets proven faulty on |

|

|

|

| inspection. |

| 5. | Slipping belts. | 5. | Tighten Belts (See monthly maintenance.) |

Follow all safety precautions whenever diagnosing or servicing the tool.

PLEASE READ THE FOLLOWING CAREFULLY

The manufacturer and/or distributor has provided the parts list and assembly diagram in this manual as a reference tool only. Neither the manufacturer or distributor makes any representation or warranty of any kind to the buyer that he or she is qualified to make any repairs to the product, or that he or she is qualified to replace any parts of the product. In fact, the manufacturer and/ or distributor expressly states that all repairs and parts replacements should be undertaken by certified and licensed technicians, and not by the buyer. The buyer assumes all risk and liability arising out of his or her repairs to the original product or replacement parts thereto, or arising out of his or her installation of replacement parts thereto.

SKU 65204/ 99918

For technical questions, please call | Page 15 |