DVC-500 specifications

The Harman Stove Company DVC-500, a prominent model in Harman's lineup, represents the pinnacle of modern pellet stove technology. Designed for both aesthetic appeal and high efficiency, the DVC-500 combines style and functionality to provide an exceptional heating solution for homes.One of the standout features of the DVC-500 is its user-friendly digital control board. This advanced system allows homeowners to easily adjust settings such as temperature, feed rate, and fan speed, all with the touch of a button. The intuitive interface simplifies operation and enhances the overall user experience. Additionally, the thermostat-compatible feature provides the convenience of maintaining a consistent temperature throughout the home.

The DVC-500 is equipped with a powerful and efficient combustion system that maximizes heat output while minimizing emissions. Its Smart Stove technology continuously monitors and adjusts the combustion process for optimal performance. This ensures that the stove operates at peak efficiency, utilizing less fuel while delivering more heat. As a result, homeowners can enjoy lower energy costs along with an eco-friendlier heating option.

The DVC-500 also boasts a spacious hopper capacity, allowing for extended burn times without the need for frequent refueling. With the ability to hold up to 55 pounds of pellets, users can enjoy hours of consistent warmth and comfort without interruption. The stove's attractive design, available in several finishes, enhances any living space while offering the robust performance expected from Harman products.

Another notable characteristic of the DVC-500 is its easy-to-clean design. The unit features a removable ash pan that simplifies disposal, ensuring that maintenance is hassle-free. Additionally, the heat exchanger is designed for efficient airflow, which enhances the stove's heating capacity while reducing the buildup of soot and debris.

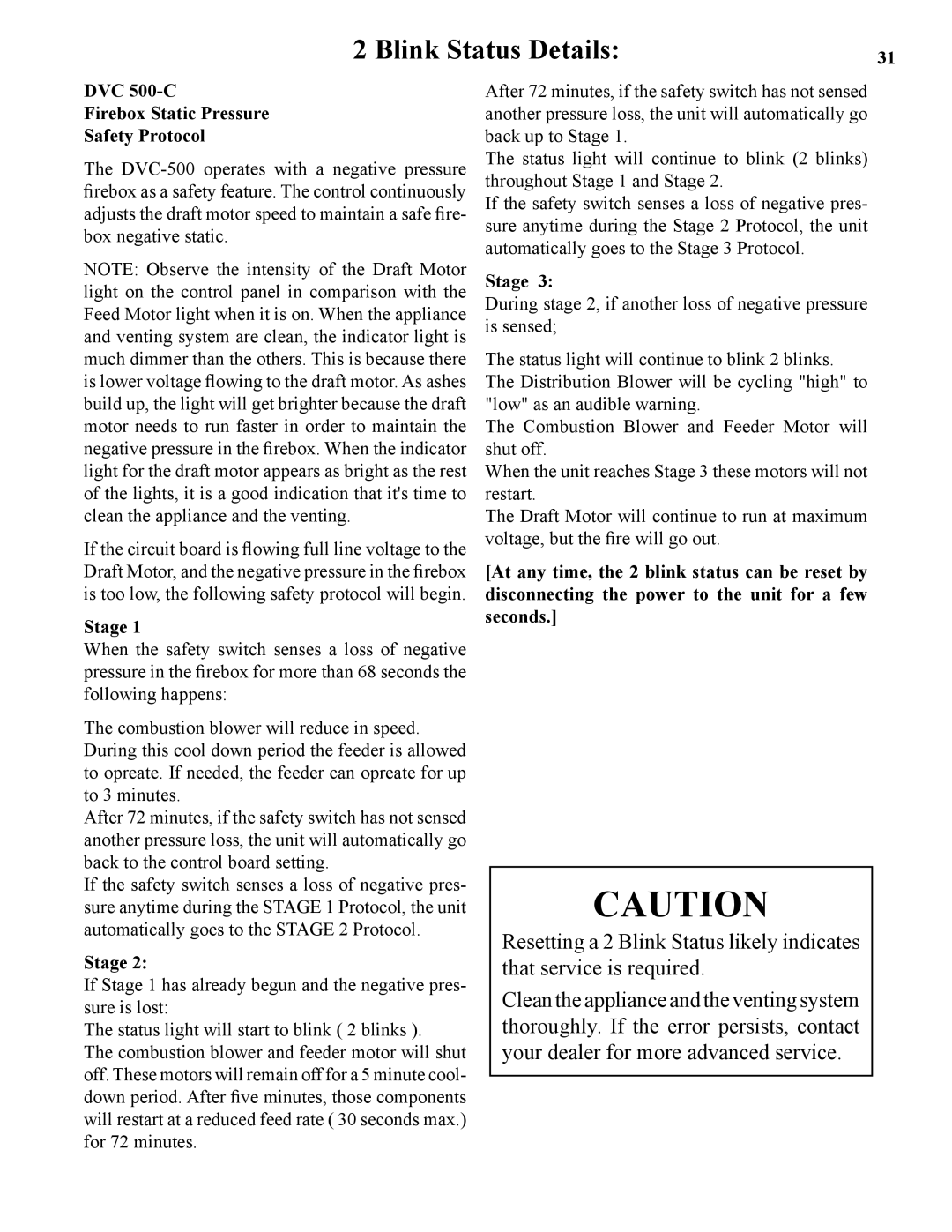

Safety is a critical consideration, and the DVC-500 incorporates several features to ensure peace of mind. The stove includes an integrated safety high-limit switch and a positive-pressure exhaust system that prevents backdraft, making it a reliable choice for any home.

In summary, the Harman Stove Company DVC-500 is a versatile, efficient, and aesthetically pleasing pellet stove that combines advanced technology with ease of use. Its intelligent control systems, high-efficiency combustion, and thoughtful design make it an excellent choice for homeowners seeking a reliable and stylish heating solution. With the DVC-500, Harman continues its legacy of quality craftsmanship and innovative heating solutions.