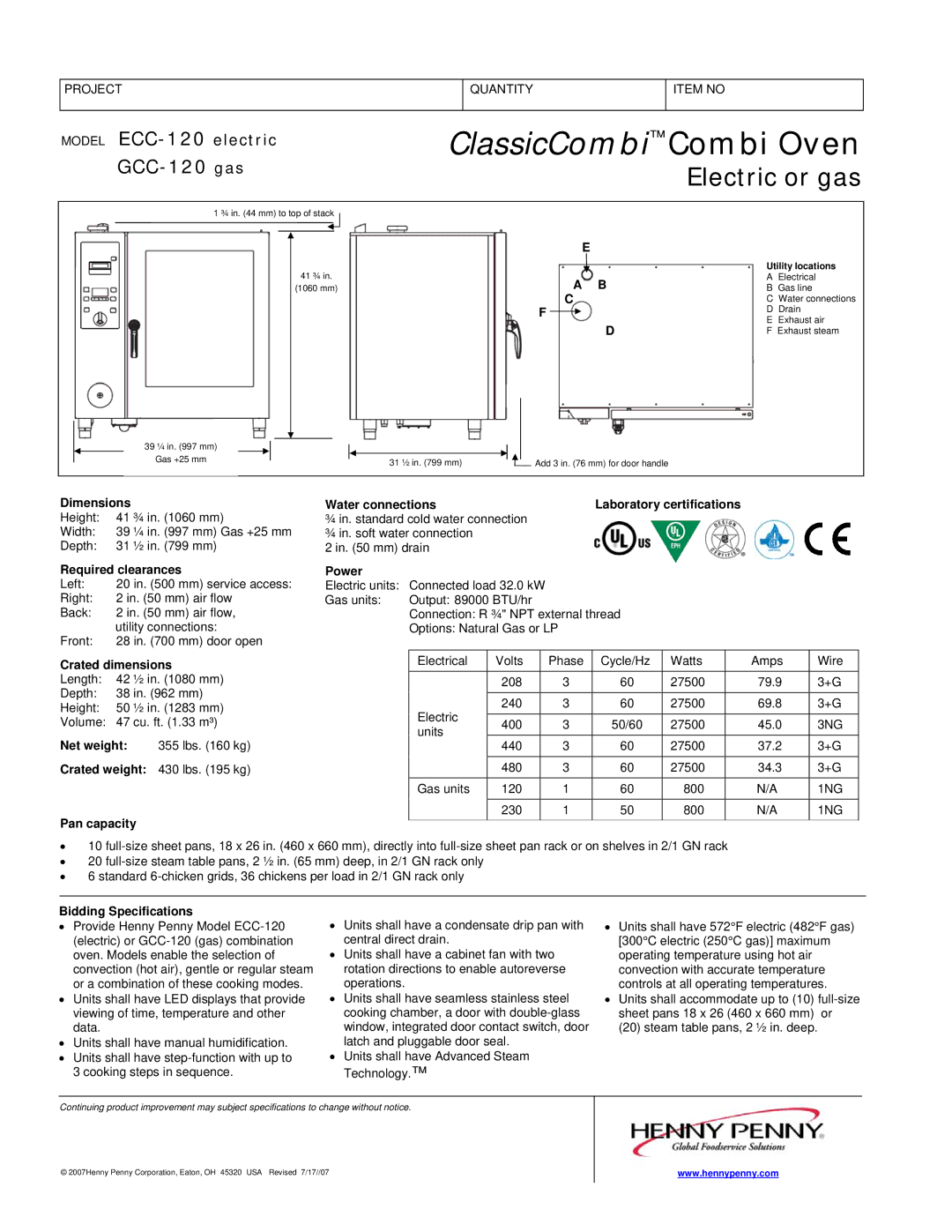

ECC-120, GCC-120, GCC-120 Gas specifications

The Henny Penny GCC-120 and ECC-120 models represent the pinnacle of gas-powered cooking technology in commercial kitchens. Designed for operators who demand efficiency without compromising quality, these units are engineered to deliver superior performance and reliability.At the heart of the GCC-120 is its advanced gas technology. The unit includes a robust gas burner system that provides consistent heat, ensuring exceptional cooking results. With precise control over cooking temperatures, chefs can achieve the perfect balance between crispy exteriors and moist interiors. The GCC-120 also features a user-friendly digital control panel, which allows for easy programming and monitoring of cooking cycles, reducing the risk of human error.

One of the standout features of the GCC-120 is its capacity. It offers ample cooking space, making it ideal for high-volume operations. The unit is designed to accommodate various food types, from fried chicken to vegetables, without compromising on quality. This versatility is essential for busy kitchens that need to cater to diverse menus.

The ECC-120 model shares many of the same features as the GCC-120, with a notable emphasis on energy efficiency and environmental responsibility. The ECC-120 employs innovative insulation technology, minimizing heat loss and improving overall energy use. This not only leads to cost savings but also contributes to a more sustainable kitchen environment.

Both models are constructed from high-quality stainless steel, ensuring durability and ease of maintenance. The smooth surfaces are designed for quick cleaning, allowing operators to maintain high hygiene standards essential in foodservice settings. The ergonomic design also helps reduce operator fatigue during long hours of cooking.

In addition to their performance capabilities, the GCC-120 and ECC-120 come equipped with safety features that are crucial in commercial kitchens. These include flame failure devices and temperature limit controls, ensuring safe operation at all times.

In summary, the Henny Penny GCC-120 and ECC-120 gas models are exemplary additions to any commercial kitchen, offering top-notch performance, energy efficiency, and a focus on safety and ease of use. Chefs can rely on these units to consistently deliver outstanding results, making them invaluable tools in the pursuit of culinary excellence.