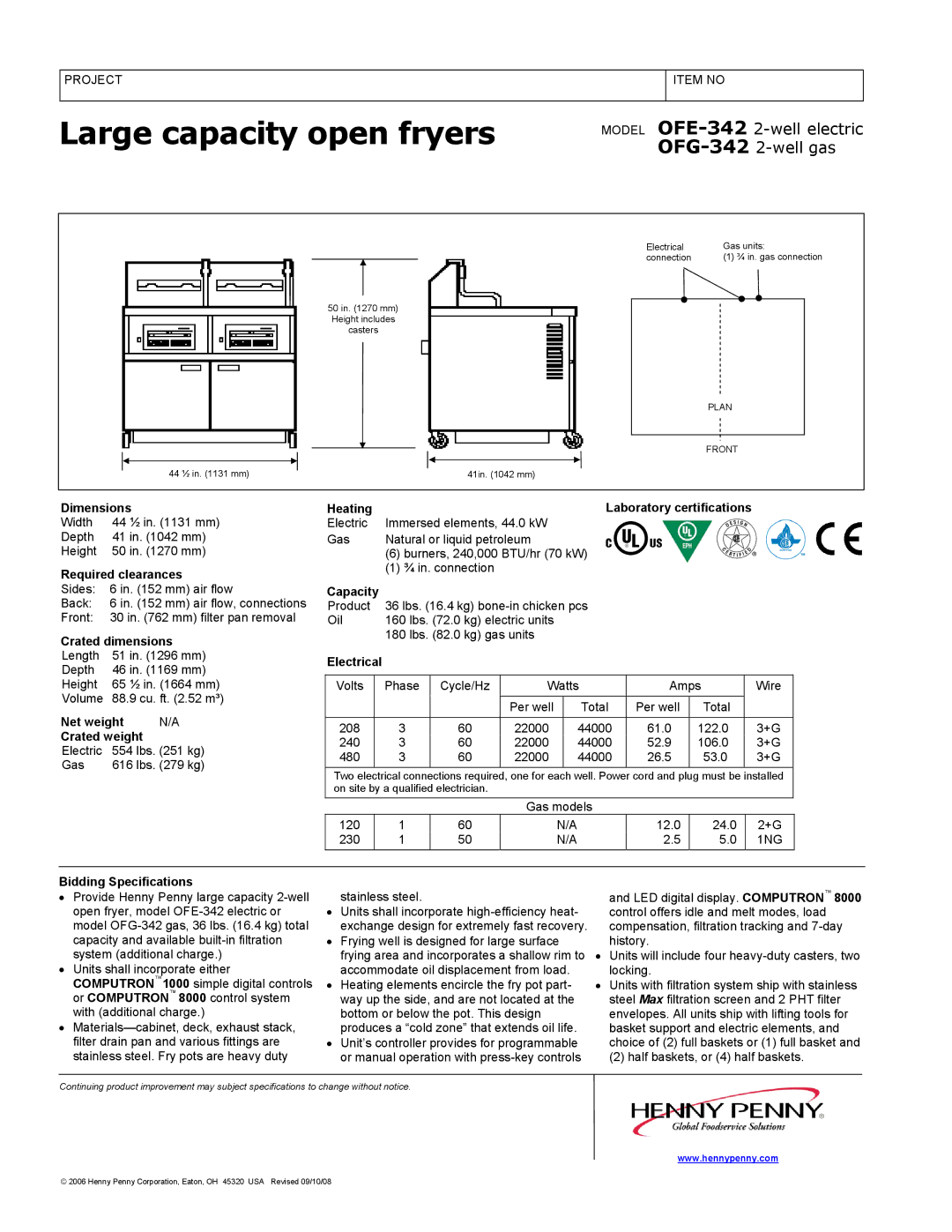

OFG-342, OFE-342 specifications

Henny Penny OFG-342 and OFE-342 represent the cutting edge of commercial cooking equipment, designed specifically to elevate food service operations in restaurants, kitchens, and catering services. Offering a perfect blend of innovation, efficiency, and versatility, these models have garnered attention from chefs and operators alike.One of the standout features of these models is their advanced cooking technology. Both the OFG-342 and OFE-342 utilize a powerful, patented cooking system that combines convection heat with a unique airflow design, ensuring even cooking and browning of food. This technology not only reduces cooking times but also enhances the overall flavor and texture of the dishes, providing customers with a superior dining experience.

Both models are equipped with digital control systems that allow for precise temperature management and cooking times. This level of control is crucial for achieving consistent results across various food items, making these ovens particularly beneficial for high-volume operations. The easy-to-use interface provides flexibility, enabling chefs to program multiple cooking cycles, which streamlines kitchen processes.

Another significant characteristic of the Henny Penny OFG-342 and OFE-342 is their energy efficiency. These models are designed to minimize energy consumption while maximizing output, helping businesses reduce operational costs without sacrificing quality. The use of high-quality insulation in the construction of the ovens ensures minimal heat loss, further contributing to energy savings.

Durability is a hallmark of the Henny Penny brand, and both the OFG-342 and OFE-342 are no exception. Constructed from robust stainless steel, these ovens are built to withstand the rigors of daily use in a busy kitchen environment. Their design not only promotes longevity but also allows for easy cleaning and maintenance, which is essential in a fast-paced food service setting.

In terms of versatility, both ovens can handle a wide range of cooking applications, from frying and baking to roasting and reheating. This flexibility makes them ideal for diverse menus, allowing restaurants to expand their offerings without the need for multiple pieces of equipment.

In summary, the Henny Penny OFG-342 and OFE-342 are exceptional cooking solutions that combine advanced technology, energy efficiency, and durable construction. Their digital controls, even cooking technology, and versatility make them indispensable tools for any food service operation aiming to enhance efficiency and elevate the quality of their offerings. As the culinary landscape continues to evolve, these ovens stand out as a reliable choice for both chefs and restaurateurs.