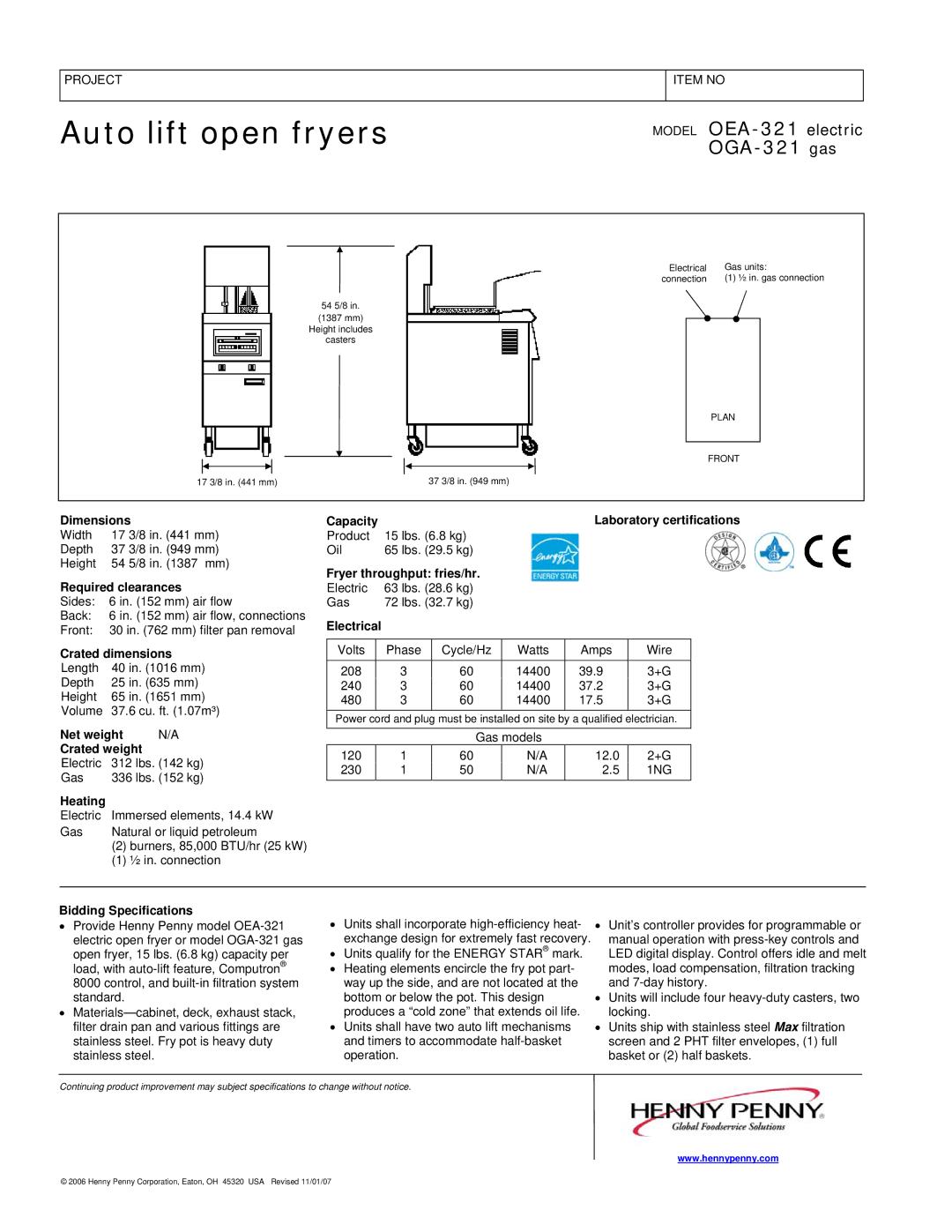

OGA-321, OEA-321, OGA-321 gas specifications

Henny Penny is a well-known name in the commercial cooking equipment industry, specializing in innovative frying solutions. Among its top offerings are the OGA-321, OEA-321, and OGA-321 gas fryers. Each model is designed to enhance cooking efficiency while ensuring consistent food quality, making them ideal for various food service operations.The OGA-321 model is particularly notable for its advanced gas heating technology, which optimizes performance while minimizing energy consumption. This fryer utilizes a unique high-efficiency burner system that directs heat more effectively. This efficiency not only speeds up cooking times but also reduces fuel costs, making it an economical choice for busy kitchen environments.

Additionally, the OGA-321 is equipped with a digital control panel that allows for precise temperature regulation, ensuring that oil remains at the ideal frying temperature. This technology also includes automated shut-off features that enhance safety and prevent overheating, making it user-friendly for kitchen staff.

Next in line, the OEA-321 fryer is engineered with a different focus, emphasizing electric frying capabilities without sacrificing quality or performance. This model is known for its rapid recovery times, which ensures that even during peak hours, the cooking process remains uninterrupted. The OEA-321 is designed with a user-friendly interface that simplifies operation and promotes efficient cooking workflows.

One of the distinguishing features of both the OGA-321 and OEA-321 is the patented filtration system. This system significantly extends the life of the cooking oil by removing food particles and impurities during the frying process. The filtration features are easy to access, allowing for quick maintenance routines that are vital in a high-paced kitchen.

Lastly, ergonomic design is a hallmark of the Henny Penny fryers. The OGA-321 and OEA-321 models include convenient access points for oil and food handling, reducing the risk of accidents and promoting worker efficiency.

In conclusion, whether you choose gas or electric, the Henny Penny OGA-321 and OEA-321 offer advanced technology and reliable features tailored to meet the demands of modern commercial kitchens. These fryers stand out for their energy efficiency, user-friendly controls, and commitment to food quality, making them excellent investments for any food service operation.