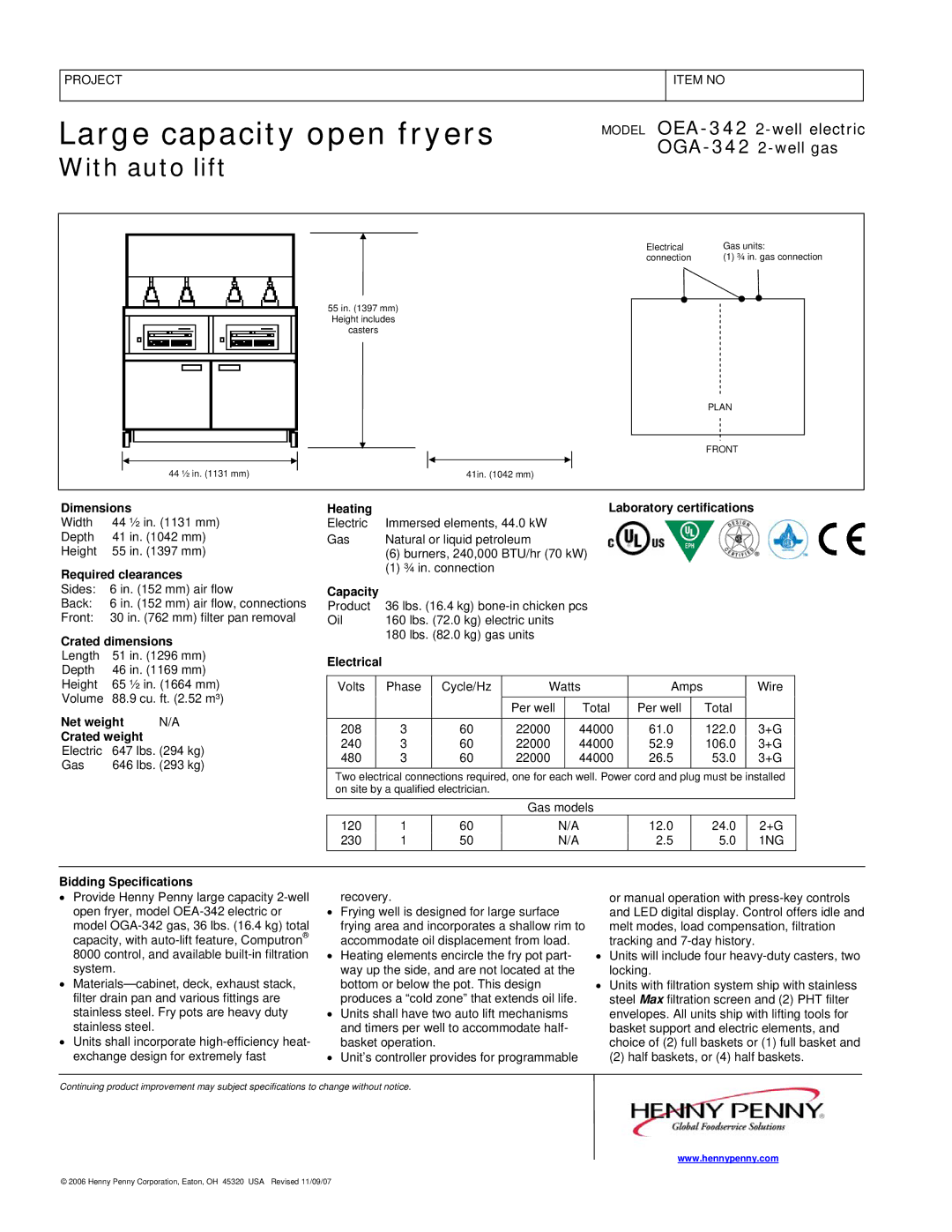

OEA-342, OGA-342 specifications

Henny Penny OEA-342 and OGA-342 are advanced cooking solutions designed for commercial kitchens, renowned for their efficiency, versatility, and innovative technology. These models reflect the commitment of Henny Penny to provide high-quality equipment that meets the diverse needs of the foodservice industry.One of the standout features of the OEA-342 is its unique design that combines a convection oven with a combi-steamer. This dual functionality allows chefs to utilize dry heat, steam, or a combination of both, offering unparalleled cooking flexibility. The OGA-342, on the other hand, focuses more on focused air circulation and precise temperature control, making it ideal for baking and roasting applications.

Both models boast advanced control systems featuring user-friendly digital displays that simplify operation. The intuitive interface allows operators to program different cooking profiles, tailoring settings for various menu items. This ease of use minimizes training time for staff, ensuring a smooth workflow in busy kitchen environments.

Energy efficiency is a hallmark of both the OEA-342 and OGA-342. These units utilize advanced insulation technologies that minimize heat loss, allowing them to maintain consistent temperatures while consuming less energy. This not only reduces operational costs but also contributes to a more sustainable kitchen environment.

Safety is prioritized in the design of Henny Penny's cooking equipment. The OEA-342 and OGA-342 are equipped with multiple safety features, including automatic shut-off mechanisms and cool-touch exteriors to minimize the risk of burns. Additionally, the units are constructed from high-quality materials that ensure durability and longevity, making them a sound investment for any commercial kitchen.

Cleaning and maintenance are essential considerations for busy foodservice operations. Both models are designed with ease of cleaning in mind, featuring removable components and smooth surfaces that prevent the buildup of grease and residues. This focus on hygiene not only helps maintain food quality but also ensures compliance with health regulations.

In summary, the Henny Penny OEA-342 and OGA-342 represent the pinnacle of modern cooking technology in commercial kitchens. Their blend of versatility, energy efficiency, safety, and ease of use makes them indispensable tools for chefs aiming to deliver exceptional dining experiences. Whether it's baking, roasting, or steaming, these units stand out as reliable solutions to meet the evolving demands of the foodservice industry.