PFE-561 specifications

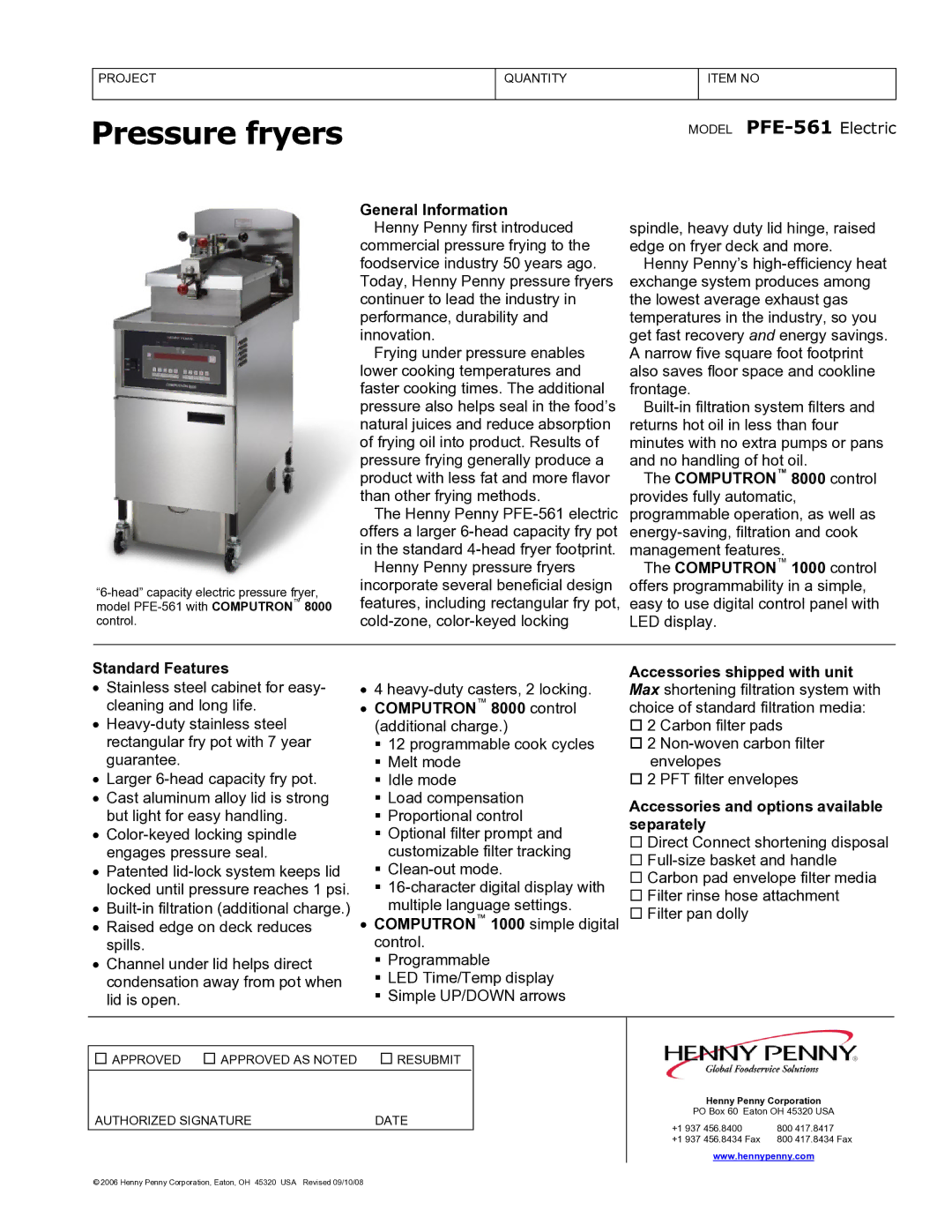

The Henny Penny PFE-561 is an advanced electric pressure fryer designed to meet the demanding needs of commercial kitchens, providing an efficient solution for cooking a variety of foods. Renowned for its reliability and performance, the PFE-561 is an ideal choice for restaurants and foodservice operations looking to enhance their frying capabilities.One of the standout features of the Henny Penny PFE-561 is its high-efficiency design. The fryer utilizes a patented heat transfer system that ensures quick and even cooking, minimizing the time required to prepare chicken, fries, and other menu items. This system not only enhances cooking speed but also improves energy savings, making the unit environmentally friendly and cost-effective to operate.

The PFE-561 is equipped with a user-friendly digital control panel that allows operators to easily set cooking temperatures and times. The intuitive interface provides clear information, enabling precise control over the frying process. Additionally, the fryer includes programmable cooking cycles, which can be customized for various foods, ensuring consistent results.

Safety is a primary concern in any commercial kitchen, and the Henny Penny PFE-561 addresses this with features such as automatic lid locking and a built-in pressure relief system. These mechanisms prevent accidental openings during operation, ensuring safe handling and cooking. Furthermore, the fryer is designed with a robust construction that can withstand the rigors of daily use while ensuring safety and durability.

Another notable characteristic of the PFE-561 is its versatility. With a capacity to handle large batches, this fryer is suitable for busy kitchens that require high-volume frying. It can cook a wide range of products, from traditional fried chicken to innovative menu items, accommodating various culinary styles.

Cleaning and maintenance of the PFE-561 are simplified with removable components and an integrated filtration system that prolongs oil life and ensures food quality. This system is vital for operational efficiency, allowing kitchens to maintain high standards without excessive downtime for frying equipment.

In conclusion, the Henny Penny PFE-561 incorporates cutting-edge technologies, ensuring high performance, safety, and versatility in frying. With its energy-efficient design, user-friendly controls, and commitment to safety, it stands out as a leading choice for commercial kitchens looking to elevate their frying capabilities. Embracing the PFE-561 means investing in quality equipment that meets the dynamic needs of today’s foodservice industry.