PFG-600 Gas specifications

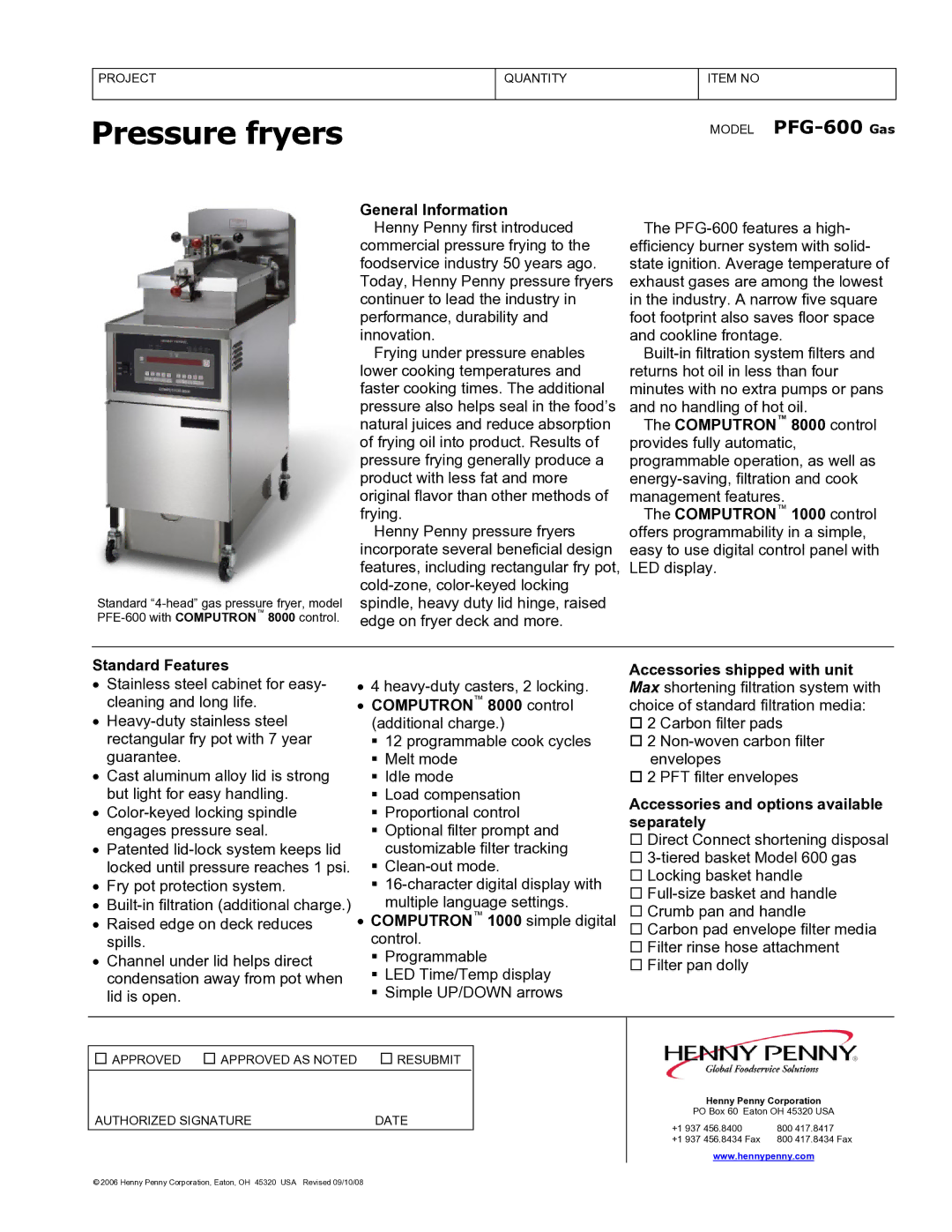

The Henny Penny PFG-600 Gas is a state-of-the-art pressure fryer designed to meet the demands of high-volume food service operations. This advanced frying solution stands out for its efficiency, innovative technologies, and ability to produce consistently crispy and flavorful fried foods.At the heart of the PFG-600 is its high-capacity frying capability, allowing operators to cook large batches of food in a single cycle. This is particularly beneficial for restaurants, catering services, and large kitchens that require fast service without compromising on quality. The fryer can accommodate a variety of products, from chicken and fish to vegetables and desserts, making it versatile for diverse menus.

One of the main features of the Henny Penny PFG-600 is its precise temperature control. The fryer utilizes advanced digital controls to maintain consistent oil temperature, ensuring optimal cooking every time. This precision not only enhances food quality but also improves oil efficiency, prolonging the life of the oil and reducing operational costs.

The PFG-600 is designed with an innovative oil filtration system that allows for easy maintenance and extended oil life. This system enables continuous frying without needing to frequently change out oil, which is a significant advantage in busy kitchens. The automated filtration process conveniently removes food particles and impurities from the oil, ensuring a clean frying environment.

Safety is also a priority with the PFG-600. It features built-in safety mechanisms such as a pressure relief valve and a secure locking lid, minimizing the risk of accidents during operation. Additionally, the fryer is equipped with an easy-to-read pressure gauge, allowing operators to monitor the frying process with confidence.

Durability is another characteristic of the Henny Penny PFG-600, constructed from high-grade stainless steel to withstand the rigors of a busy kitchen. The fryer’s robust design ensures longevity and reliable performance, making it a smart investment for food service operations.

Moreover, the PFG-600 is designed for ease of use, featuring user-friendly controls that simplify operation for staff. This intuitive interface allows for quicker training and minimizes the potential for errors, enhancing overall kitchen efficiency.

In conclusion, the Henny Penny PFG-600 Gas fryer combines high capacity, advanced technologies, and a focus on safety and durability, making it an essential tool for any high-volume kitchen. Its ability to deliver top-quality fried foods consistently, along with easy maintenance and operator-friendly features, solidifies its position as a leading choice in commercial frying equipment.