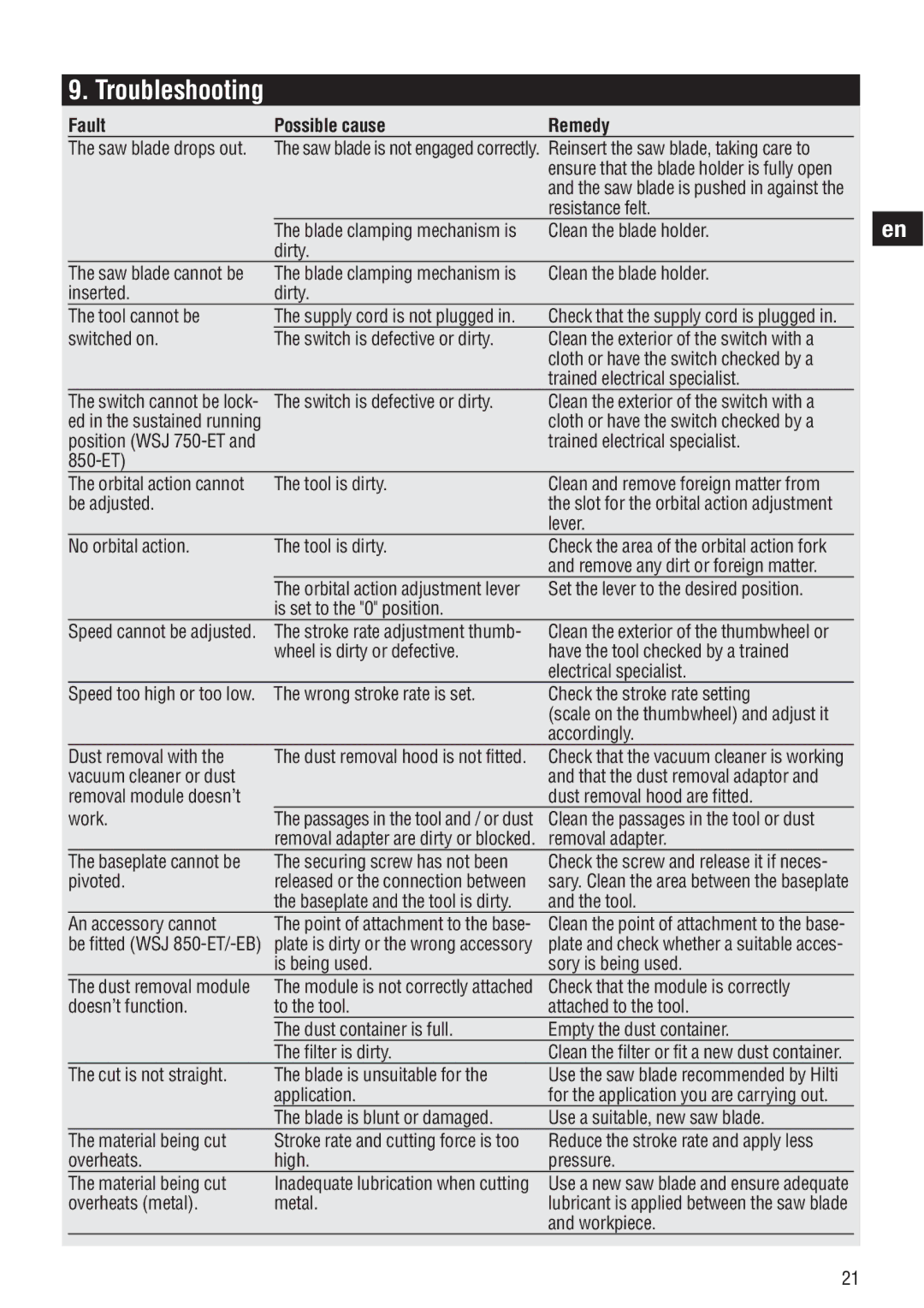

9. Troubleshooting

Fault | Possible cause | Remedy |

| ||

The saw blade drops out. | The saw blade is not engaged correctly. Reinsert the saw blade, taking care to |

|

| ||

|

|

| ensure that the blade holder is fully open |

| |

|

|

| and the saw blade is pushed in against the |

| |

|

|

| resistance felt. |

| |

|

|

| en | ||

|

| The blade clamping mechanism is | Clean the blade holder. |

| |

| dirty. |

|

|

| |

The saw blade cannot be | The blade clamping mechanism is | Clean the blade holder. |

|

| |

inserted. | dirty. |

|

|

| |

The tool cannot be | The supply cord is not plugged in. | Check that the supply cord is plugged in. |

|

| |

switched on. | The switch is defective or dirty. | Clean the exterior of the switch with a |

|

| |

|

|

| cloth or have the switch checked by a |

| |

|

|

| trained electrical specialist. |

|

|

The switch cannot be lock- The switch is defective or dirty. ed in the sustained running

position (WSJ

Clean the exterior of the switch with a cloth or have the switch checked by a trained electrical specialist.

The orbital action cannot | The tool is dirty. | Clean and remove foreign matter from |

be adjusted. |

| the slot for the orbital action adjustment |

|

| lever. |

No orbital action. | The tool is dirty. | Check the area of the orbital action fork |

|

| and remove any dirt or foreign matter. |

| The orbital action adjustment lever | Set the lever to the desired position. |

| is set to the "0" position. |

|

Speed cannot be adjusted. The stroke rate adjustment thumb- wheel is dirty or defective.

Clean the exterior of the thumbwheel or have the tool checked by a trained electrical specialist.

Speed too high or too low. | The wrong stroke rate is set. | Check the stroke rate setting | |

|

|

| (scale on the thumbwheel) and adjust it |

|

|

| accordingly. |

Dust removal with the | The dust removal hood is not fitted. | Check that the vacuum cleaner is working | |

vacuum cleaner or dust |

|

| and that the dust removal adaptor and |

removal module doesn’t |

|

| dust removal hood are fitted. |

work. |

| The passages in the tool and / or dust | Clean the passages in the tool or dust |

| removal adapter are dirty or blocked. | removal adapter. | |

The baseplate cannot be | The securing screw has not been | Check the screw and release it if neces- | |

pivoted. | released or the connection between | sary. Clean the area between the baseplate | |

| the baseplate and the tool is dirty. | and the tool. | |

An accessory cannot | The point of attachment to the base- | Clean the point of attachment to the base- | |

be fitted (WSJ | plate is dirty or the wrong accessory | plate and check whether a suitable acces- | |

| is being used. | sory is being used. | |

The dust removal module | The module is not correctly attached | Check that the module is correctly | |

doesn’t function. | to the tool. | attached to the tool. | |

| The dust container is full. | Empty the dust container. | |

| The filter is dirty. | Clean the filter or fit a new dust container. | |

The cut is not straight. | The blade is unsuitable for the | Use the saw blade recommended by Hilti | |

| application. | for the application you are carrying out. | |

| The blade is blunt or damaged. | Use a suitable, new saw blade. | |

The material being cut | Stroke rate and cutting force is too | Reduce the stroke rate and apply less | |

overheats. | high. | pressure. | |

The material being cut | Inadequate lubrication when cutting | Use a new saw blade and ensure adequate | |

overheats (metal). |

| metal. | lubricant is applied between the saw blade |

|

|

| and workpiece. |

21