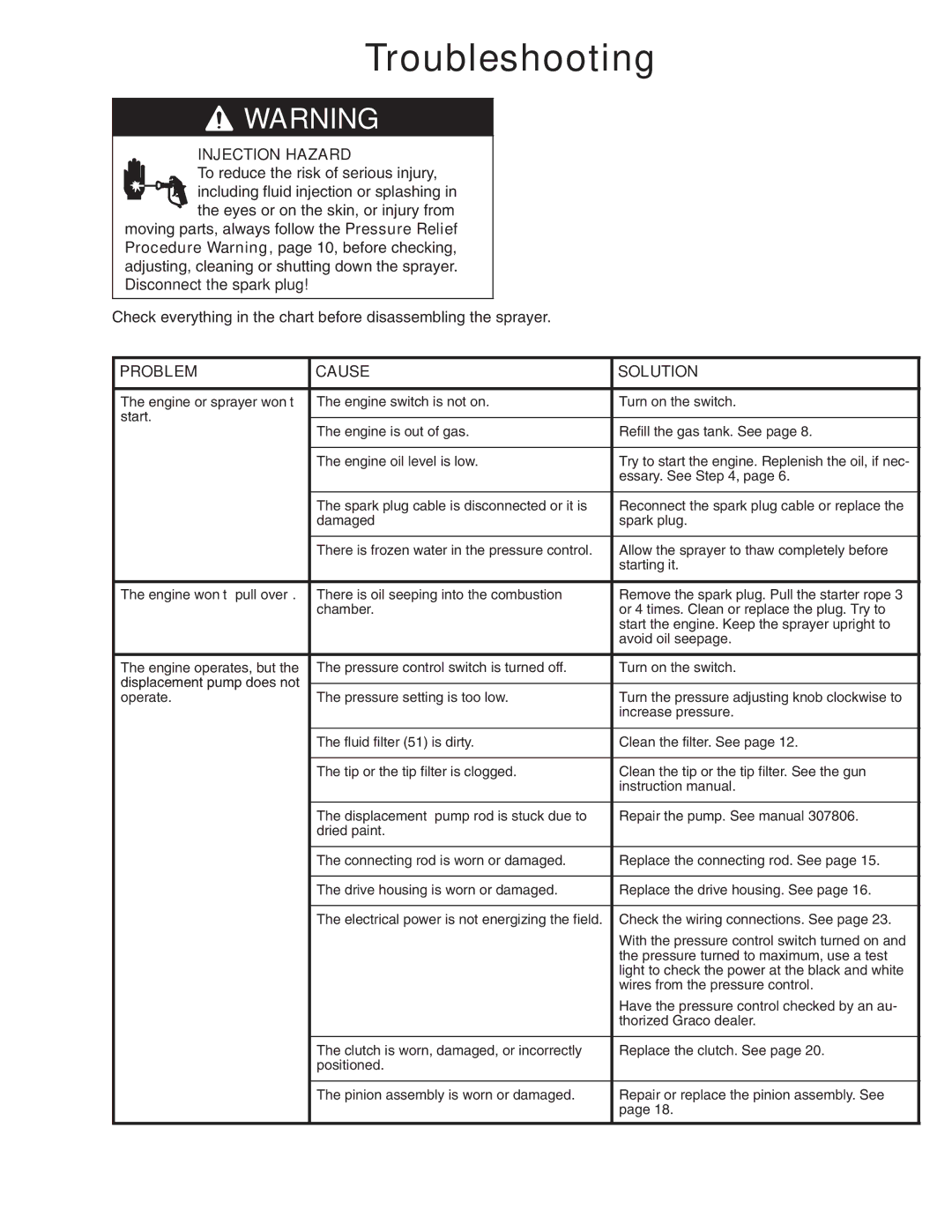

Troubleshooting

![]() WARNING

WARNING

INJECTION HAZARD

To reduce the risk of serious injury, including fluid injection or splashing in

the eyes or on the skin, or injury from moving parts, always follow the Pressure Relief Procedure Warning, page 10, before checking, adjusting, cleaning or shutting down the sprayer. Disconnect the spark plug!

Check everything in the chart before disassembling the sprayer.

PROBLEM | CAUSE | SOLUTION | |

|

|

| |

The engine or sprayer won’t | The engine switch is not on. | Turn on the switch. | |

start. |

|

| |

The engine is out of gas. | Refill the gas tank. See page 8. | ||

| |||

|

|

| |

| The engine oil level is low. | Try to start the engine. Replenish the oil, if nec- | |

|

| essary. See Step 4, page 6. | |

|

|

| |

| The spark plug cable is disconnected or it is | Reconnect the spark plug cable or replace the | |

| damaged | spark plug. | |

|

|

| |

| There is frozen water in the pressure control. | Allow the sprayer to thaw completely before | |

|

| starting it. | |

|

|

| |

The engine won’t “pull over”. | There is oil seeping into the combustion | Remove the spark plug. Pull the starter rope 3 | |

| chamber. | or 4 times. Clean or replace the plug. Try to | |

|

| start the engine. Keep the sprayer upright to | |

|

| avoid oil seepage. | |

|

|

| |

The engine operates, but the | The pressure control switch is turned off. | Turn on the switch. | |

displacement pump does not |

|

| |

|

| ||

operate. | The pressure setting is too low. | Turn the pressure adjusting knob clockwise to | |

|

| increase pressure. | |

|

|

| |

| The fluid filter (51) is dirty. | Clean the filter. See page 12. | |

|

|

| |

| The tip or the tip filter is clogged. | Clean the tip or the tip filter. See the gun | |

|

| instruction manual. | |

|

|

| |

| The | Repair the pump. See manual 307806. | |

| dried paint. |

| |

|

|

| |

| The connecting rod is worn or damaged. | Replace the connecting rod. See page 15. | |

|

|

| |

| The drive housing is worn or damaged. | Replace the drive housing. See page 16. | |

|

|

| |

| The electrical power is not energizing the field. | Check the wiring connections. See page 23. | |

|

| With the pressure control switch turned on and | |

|

| the pressure turned to maximum, use a test | |

|

| light to check the power at the black and white | |

|

| wires from the pressure control. | |

|

| Have the pressure control checked by an au- | |

|

| thorized Graco dealer. | |

|

|

| |

| The clutch is worn, damaged, or incorrectly | Replace the clutch. See page 20. | |

| positioned. |

| |

|

|

| |

| The pinion assembly is worn or damaged. | Repair or replace the pinion assembly. See | |

|

| page 18. | |

|

|

|

308398 13