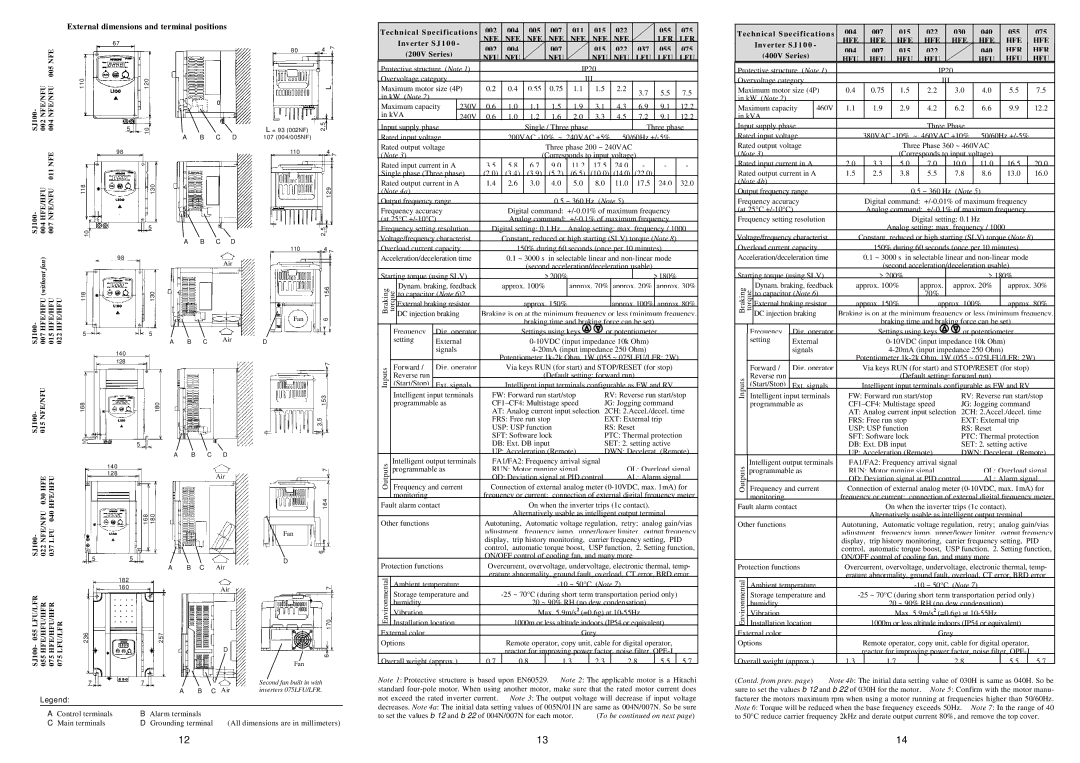

SJ100 specifications

The Hitachi SJ100 series represents a significant advancement in the field of variable frequency drives (VFDs), designed to enhance energy efficiency and operational reliability in various industrial applications. Compact in design yet powerful, the SJ100 is tailored for a wide range of tasks, making it a versatile addition to any automation system.One of the standout features of the SJ100 is its superior control technology, which utilizes advanced vector control methods to ensure optimal motor performance. This allows for precise speed and torque control, leading to enhanced responsiveness and reduced energy consumption. The drive is also capable of handling a diverse array of motor types, including induction and permanent magnet motors, making it suitable for numerous industrial sectors.

The SJ100 incorporates a robust set of built-in features designed to simplify installation and operation. With an easy-to-navigate LCD control panel, users can quickly set parameters and monitor performance. Additionally, the drive includes a variety of communication options, such as Modbus and CANopen, facilitating seamless integration into existing control systems. This adaptability ensures that the SJ100 can be utilized in various setups, from simple single-drive configurations to complex multi-drive systems.

Another notable characteristic of the SJ100 is its energy-saving capabilities. With advanced algorithms and optimized motor control, the drive significantly reduces energy consumption under varying load conditions. This feature not only helps decrease operational costs but also contributes to a more sustainable and environmentally friendly approach to industrial processes.

Moreover, the SJ100 series boasts a high degree of reliability thanks to its robust construction and protective features. It includes integrated protection against over-temperature, over-current, and voltage fluctuations, ensuring the drive operates safely in demanding environments. The SJ100 is also designed with a wide operating temperature range, allowing it to perform reliably in extreme conditions.

Additionally, the drive supports a variety of customizable functions, such as programmable logic, acceleration/deceleration control, and multi-function inputs/outputs. These features empower users to tailor the SJ100 to meet specific application requirements, enhancing productivity and operational efficiency.

In summary, the Hitachi SJ100 series stands out as a cutting-edge solution for industrial automation, combining advanced control technologies, energy efficiency, and robust reliability. Its versatility and user-friendly features make it an exceptional choice for a myriad of applications, reinforcing Hitachi's commitment to innovation in the field of industrial drives.