5-5. GMAW (MIG) Aluminum Welding Hints

Here are several hints to help you be more successful with your new aluminum feed system.

MIG welding aluminum requires different techniques than MIG welding mild steel.

A. Before You Start Welding

SMaterial thickness that can be welded with MIG process or aluminum are 14 ga. [0.074 in. (1.9 mm)] or heavier. (How heavy depends on the output capacity of the welder being used.) To MIG weld aluminum thinner than 14 ga. either specialized pulsed MIG or AC TIG welding equipment may be necessary.

SThe removal of lubricants from the aluminum base material may be necessary. Consult with your local welding distributor for their recommendation on aluminum cleaners.

SOxide removal should be done after degreasing. This should be done with a stainless steel wire brush. This can be done with a hand wire brush or with a cup wire brush. If a power wire brush is used, keep the RPM’s and pressures low to reduce smearing the surface of the material, which could entrap oxides and impurities under the surface. Always use a wire brush that is used only on aluminum to keep from contaminating the base material.

SContact you local welding distributor or aluminum filler metal representative for recommendations on wire alloys that fit your application. Know the alloy of your base aluminum and what conditions the finished part will be subjected to. The two most readily available aluminum filler wires are ER4043 and ER5356.

B. Welding Techniques

SMake sure the welding power source is set up to weld DCEP (DC Electrode Positive).

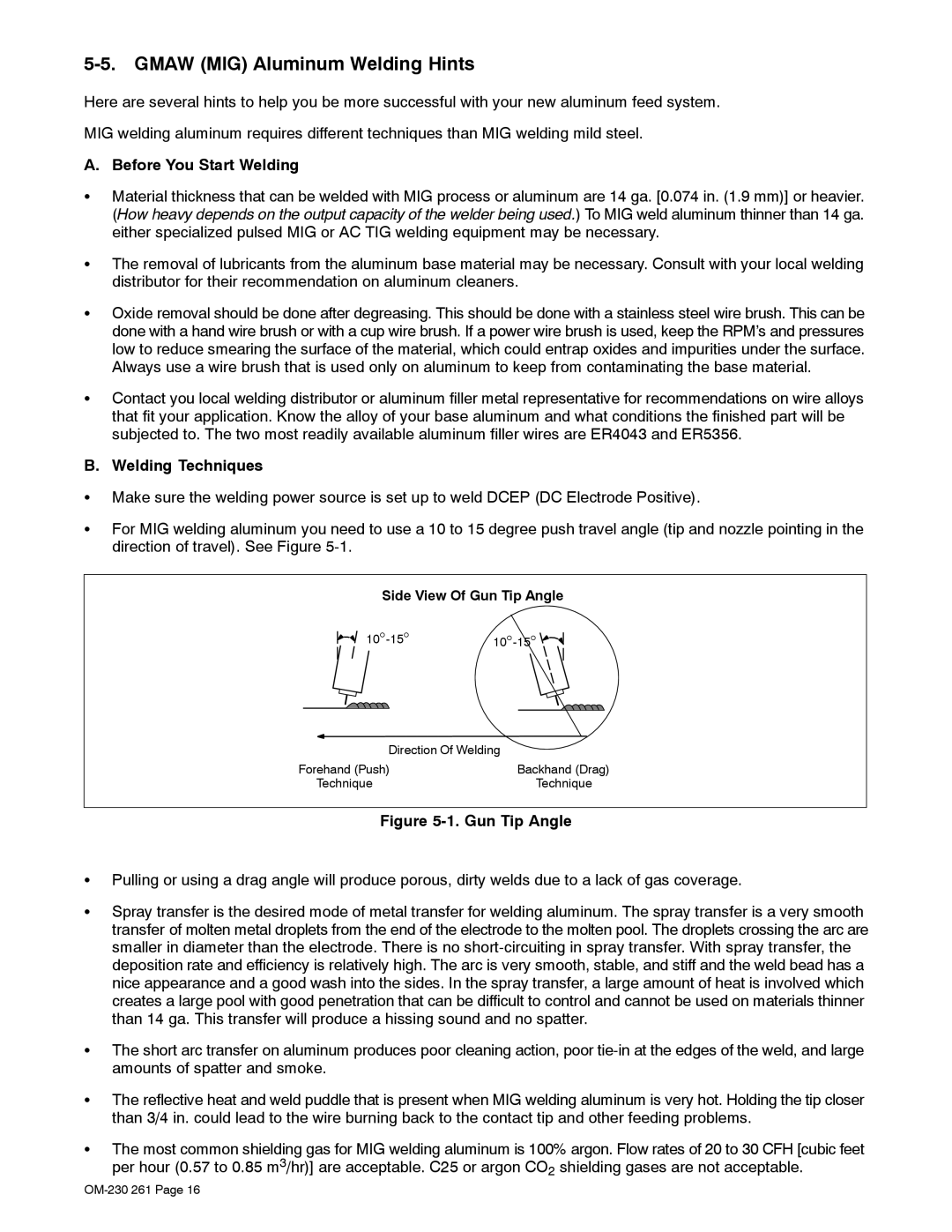

SFor MIG welding aluminum you need to use a 10 to 15 degree push travel angle (tip and nozzle pointing in the direction of travel). See Figure

Side View Of Gun Tip Angle

![]()

![]()

Direction Of Welding |

|

Forehand (Push) | Backhand (Drag) |

Technique | Technique |

Figure 5-1. Gun Tip Angle

SPulling or using a drag angle will produce porous, dirty welds due to a lack of gas coverage.

SSpray transfer is the desired mode of metal transfer for welding aluminum. The spray transfer is a very smooth transfer of molten metal droplets from the end of the electrode to the molten pool. The droplets crossing the arc are smaller in diameter than the electrode. There is no

SThe short arc transfer on aluminum produces poor cleaning action, poor

SThe reflective heat and weld puddle that is present when MIG welding aluminum is very hot. Holding the tip closer than 3/4 in. could lead to the wire burning back to the contact tip and other feeding problems.

SThe most common shielding gas for MIG welding aluminum is 100% argon. Flow rates of 20 to 30 CFH [cubic feet per hour (0.57 to 0.85 m3/hr)] are acceptable. C25 or argon CO2 shielding gases are not acceptable.