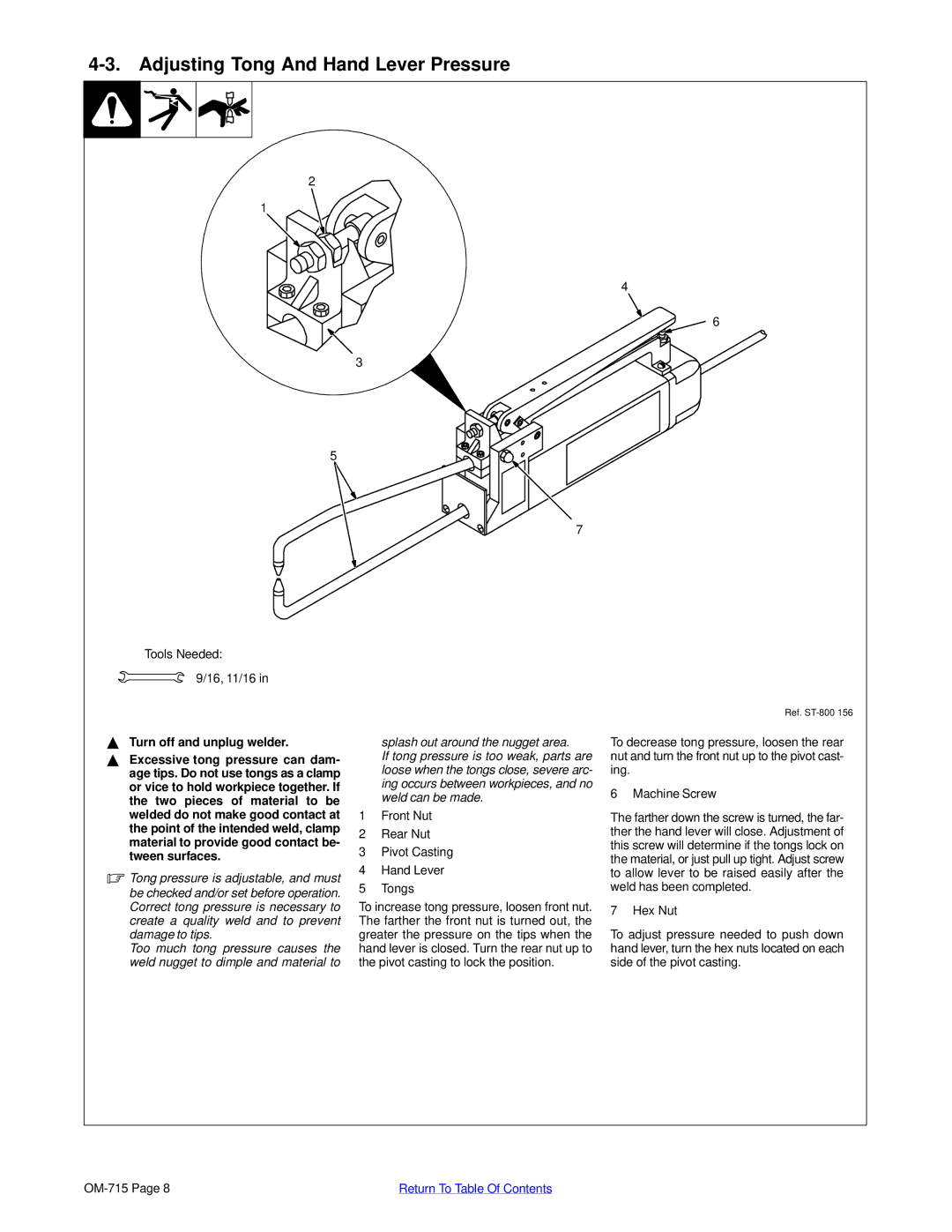

4-3. Adjusting Tong And Hand Lever Pressure

2

1

4

6

3

5

7

Tools Needed:

9/16, 11/16 in

Ref.

YTurn off and unplug welder.

YExcessive tong pressure can dam- age tips. Do not use tongs as a clamp or vice to hold workpiece together. If the two pieces of material to be welded do not make good contact at the point of the intended weld, clamp material to provide good contact be- tween surfaces.

.Tong pressure is adjustable, and must be checked and/or set before operation. Correct tong pressure is necessary to create a quality weld and to prevent damage to tips.

Too much tong pressure causes the weld nugget to dimple and material to

splash out around the nugget area.

If tong pressure is too weak, parts are loose when the tongs close, severe arc- ing occurs between workpieces, and no weld can be made.

1Front Nut

2Rear Nut

3Pivot Casting

4Hand Lever

5Tongs

To increase tong pressure, loosen front nut. The farther the front nut is turned out, the greater the pressure on the tips when the hand lever is closed. Turn the rear nut up to the pivot casting to lock the position.

To decrease tong pressure, loosen the rear nut and turn the front nut up to the pivot cast- ing.

6 Machine Screw

The farther down the screw is turned, the far- ther the hand lever will close. Adjustment of this screw will determine if the tongs lock on the material, or just pull up tight. Adjust screw to allow lever to be raised easily after the weld has been completed.

7 Hex Nut

To adjust pressure needed to push down hand lever, turn the hex nuts located on each side of the pivot casting.

Return To Table Of Contents |