#13070100 - COMPTIPTM RETROFIT INSTRUCTIONS | #13070100 / Page 1 of 1 | |||||

| HOBIE 14, 16, 18 AND HR14 |

| ||||

1) REMOVE MAST TANG OR TANGS (HR14) BY DRILLING OFF RIVET |

|

| ||||

|

| |||||

HEADS W/ A 13/64” (4 MM) DRILL BIT AND PUNCHING RIVET CASINGS |

|

| ||||

AND CAPS THROUGH. |

|

|

|

|

|

|

2) MEASURE FROM THE BOTTOM OF THE |

|

|

|

| ||

CUT LENGTHS ARE: |

|

|

| |||

MAST EXTRUSION (NOT INCLUDING MAST | H14 | I5' | 1 1/8" |

|

|

|

BASE). NOTE: CUT SHOULD BE ABOVE | H16 | 18’ | 3 3/4" |

|

|

|

TANG RIVET HOLES! | H18 | 20’ | 5 3/8" |

|

|

|

MARK AND CUT OFF MAST SQUARE AT THE | HR14 14' | 4 3/8" |

|

|

| |

|

|

|

|

|

| |

APPROPRIATE LENGTH. (HINT: WRAP A |

|

|

|

|

|

|

SHEET OF PAPER AROUND THE MAST AND LINE UP EDGES TO MAKE |

|

| ||||

A PERFECTLY SQUARE MARK ALL AROUND THE MAST. TAPE IN |

|

| ||||

PLACE AT THE CUT POINT. PENCIL A THICK LINE ALL AROUND THE |

|

| ||||

MAST FOLLOWING THE PAPERS EDGE. WITH A HACK SAW, START |

|

| ||||

CUTTING ON THE LINE AND ROLL THE MAST OVER AS YOU CUT. CUT |

|

| ||||

A “TRENCH” ALL AROUND THE MAST BEFORE CUTTING THROUGH |

|

| ||||

WHILE ROLLING THE MAST SLOWLY OVER. (STARTING A CUT AND |

|

| ||||

|

| |||||

CONTINUING STRAIGHT THROUGH MAY NOT CUT STRAIGHT.) |

| |||||

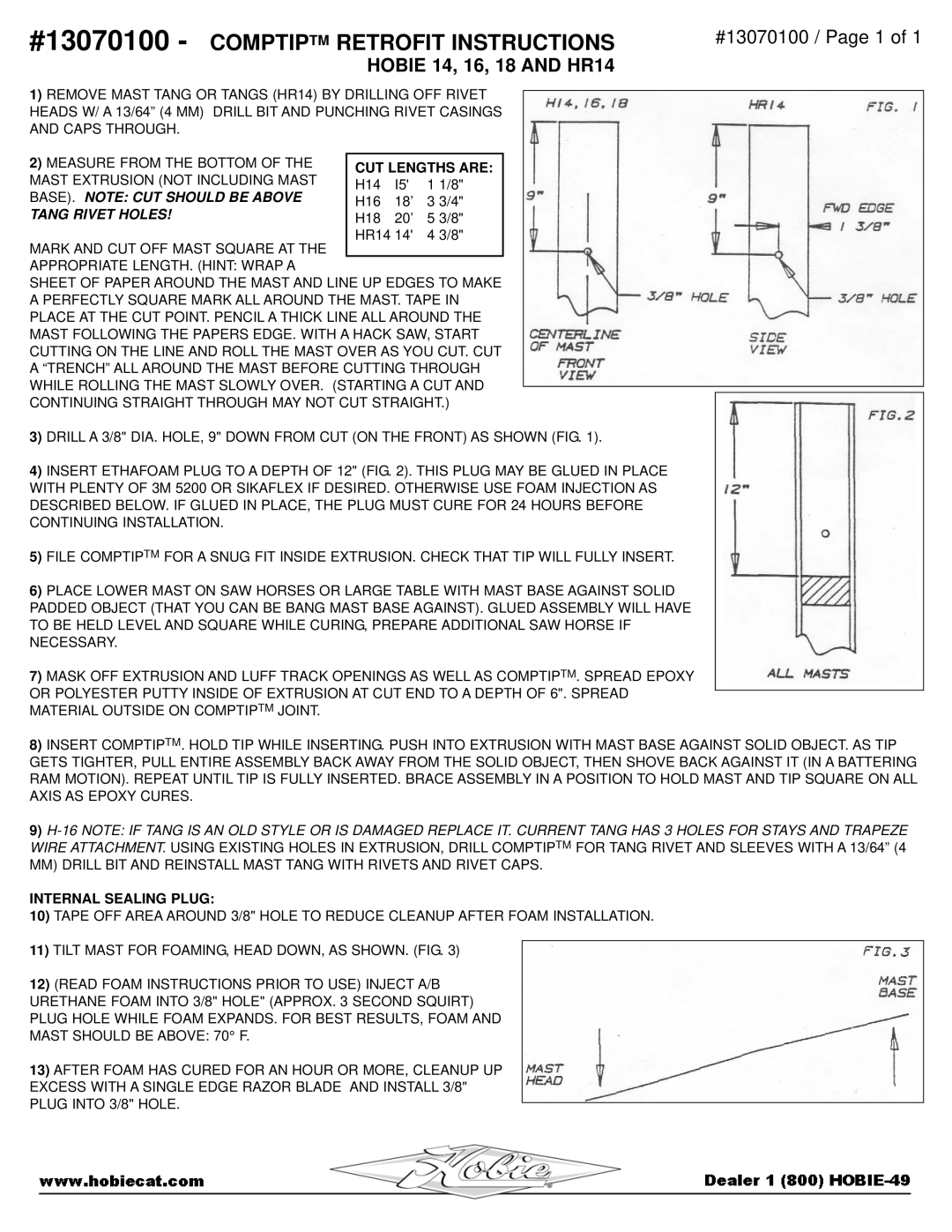

3)DRILL A 3/8" DIA. HOLE, 9" DOWN FROM CUT (ON THE FRONT) AS SHOWN (FIG. 1).

4)INSERT ETHAFOAM PLUG TO A DEPTH OF 12" (FIG. 2). THIS PLUG MAY BE GLUED IN PLACE WITH PLENTY OF 3M 5200 OR SIKAFLEX IF DESIRED. OTHERWISE USE FOAM INJECTION AS DESCRIBED BELOW. IF GLUED IN PLACE, THE PLUG MUST CURE FOR 24 HOURS BEFORE CONTINUING INSTALLATION.

5)FILE COMPTIPTM FOR A SNUG FIT INSIDE EXTRUSION. CHECK THAT TIP WILL FULLY INSERT.

6)PLACE LOWER MAST ON SAW HORSES OR LARGE TABLE WITH MAST BASE AGAINST SOLID

PADDED OBJECT (THAT YOU CAN BE BANG MAST BASE AGAINST). GLUED ASSEMBLY WILL HAVE TO BE HELD LEVEL AND SQUARE WHILE CURING, PREPARE ADDITIONAL SAW HORSE IF NECESSARY.

7)MASK OFF EXTRUSION AND LUFF TRACK OPENINGS AS WELL AS COMPTIPTM. SPREAD EPOXY OR POLYESTER PUTTY INSIDE OF EXTRUSION AT CUT END TO A DEPTH OF 6". SPREAD MATERIAL OUTSIDE ON COMPTIPTM JOINT.

8)INSERT COMPTIPTM. HOLD TIP WHILE INSERTING. PUSH INTO EXTRUSION WITH MAST BASE AGAINST SOLID OBJECT. AS TIP GETS TIGHTER, PULL ENTIRE ASSEMBLY BACK AWAY FROM THE SOLID OBJECT, THEN SHOVE BACK AGAINST IT (IN A BATTERING RAM MOTION). REPEAT UNTIL TIP IS FULLY INSERTED. BRACE ASSEMBLY IN A POSITION TO HOLD MAST AND TIP SQUARE ON ALL AXIS AS EPOXY CURES.

9)

INTERNAL SEALING PLUG:

10)TAPE OFF AREA AROUND 3/8" HOLE TO REDUCE CLEANUP AFTER FOAM INSTALLATION.

11)TILT MAST FOR FOAMING, HEAD DOWN, AS SHOWN. (FIG. 3)

12)(READ FOAM INSTRUCTIONS PRIOR TO USE) INJECT A/B

URETHANE FOAM INTO 3/8" HOLE" (APPROX. 3 SECOND SQUIRT)

PLUG HOLE WHILE FOAM EXPANDS. FOR BEST RESULTS, FOAM AND

MAST SHOULD BE ABOVE: 70° F.

13)AFTER FOAM HAS CURED FOR AN HOUR OR MORE, CLEANUP UP EXCESS WITH A SINGLE EDGE RAZOR BLADE AND INSTALL 3/8" PLUG INTO 3/8" HOLE.