When you must turn, raise the tiller high enough to just clear the ground,

LNQEZJ DO not attempt to turn corners with the tiller in the ground as this could result in damage to the tiller and/or tractor lift linkage.

Do not attempt to till or move in the reverse direction with the tiller on the ground or damage will result to the tiller andor the tractor.

TRANSPORTING

When the tiller is in the fully raised (transport) position, the maximum operating angles of the driveline universaljoints are exceeded. Do not engage the PTO when the tiller is in the transport position.

3 Replace all damaged parts. Parts are available | I |

from your Honda | |

Dealer. |

|

4Clean any rust from the tiller and repaint as required to maintain the appearance of the tiller.

5Replace all missing, illegible, or damaged safety and warning labels. See list of labels in this manual.

6Store tiller in a clean dry area.

MAINTENANCE

BEFORE EACH USE

Check tractor tire pressure (refer to tractor preparation section of this manual). Lubricate tiller driveline as described in lubrication section of this manual.

Check tiller tines and rotor to be sure that no foreign objects such as wire or steel strapping bands are wrapped around them.

DETACHING TILLER FROM TRACTOR

1Lower the tiller to the ground. Turn off the engine, remove the key and apply the tractor brakes.

2Disconnect the hitch upper link from the tiller end.

3Disconnect the two lower hitch lift arms from the tiller.

4Disconnect the tiller driveline from the tractor PTO by pushing on the PTO locking collar and pulling back on the driveline.

TINES

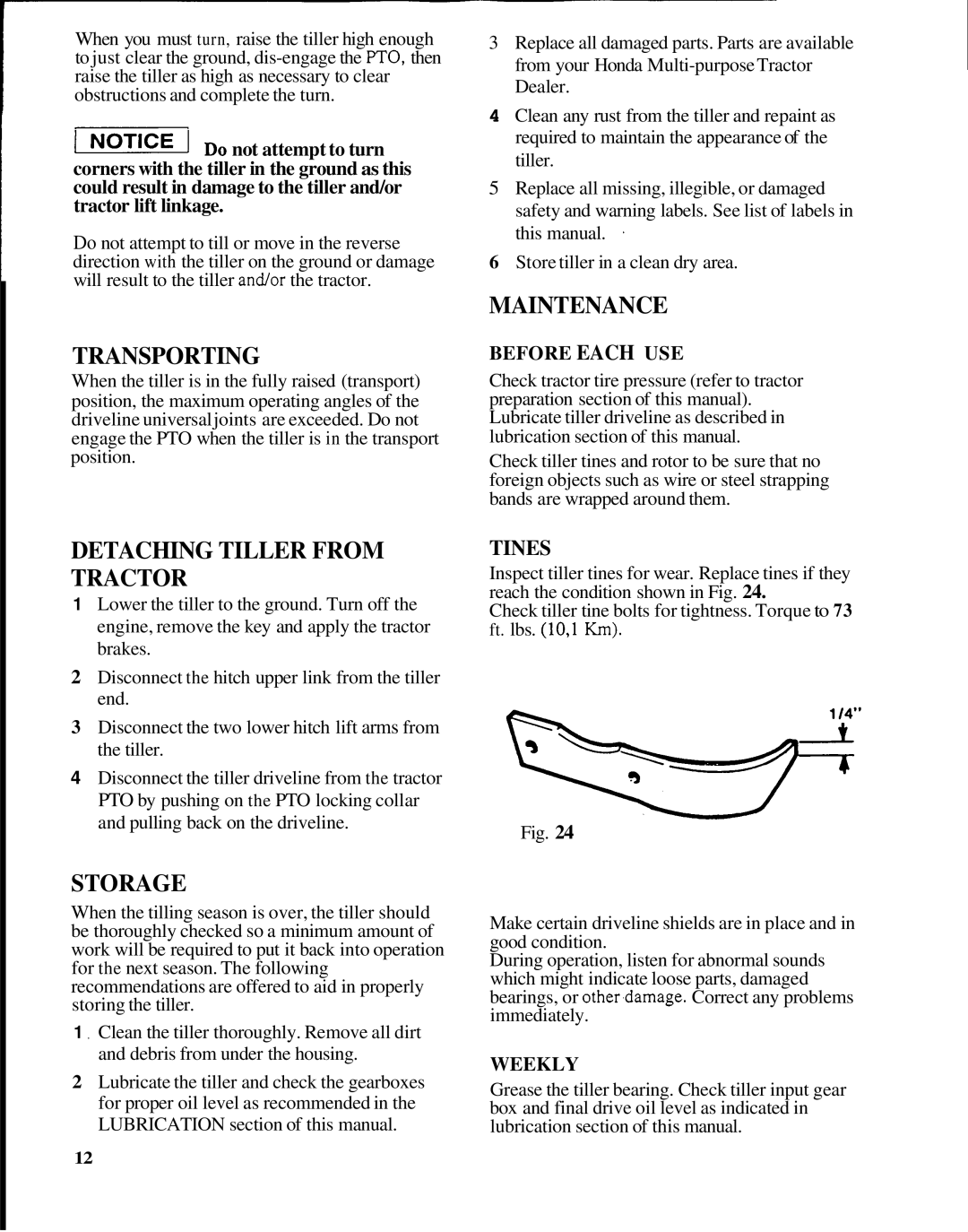

Inspect tiller tines for wear. Replace tines if they reach the condition shown in Fig. 24.

Check tiller tine bolts for tightness. Torque to 73 ft. lbs. (10,l Km).

Fig. 24

STORAGE

When the tilling season is over, the tiller should be thoroughly checked so a minimum amount of work will be required to put it back into operation for the next season. The following recommendations are offered to aid in properly storing the tiller.

1 , Clean the tiller thoroughly. Remove all dirt and debris from under the housing.

2Lubricate the tiller and check the gearboxes for proper oil level as recommended in the LUBRICATION section of this manual.

Make certain driveline shields are in place and in good condition.

During operation, listen for abnormal sounds which might indicate loose parts, damaged bearings, or otherdamage. Correct any problems immediately.

WEEKLY

Grease the tiller bearing. Check tiller input gear box and final drive oil level as indicated in lubrication section of this manual.

12