Safety Non Contact Switch |

Based on Magnetic Coded Technology

FEATURES

•Meets applicable parts of European EN 1088 standard for Interlocking devices associated with guards

•Permanent

•Operating range:

5 mm - 7 mm / 0.20 in - 0.27 in ON,

8 mm - 12 mm / 0.32 in - 0.47 in OFF

•High resistance to environmental influences

•ABS and Stainless Steel housings sensors available

•Sensors sealing: IP 67

•Prewired or M8 plug termination

•Supply voltage: 24 Vdc/Vac ±15 %; 110 Vac ±15 % (only available for the

•Response time of the control unit:

15 ms

•Manual or automatic restart

•LED status indicator

•

22,5 mm / 0.89 in width)

75 mm / 2.95 in width)

TYPICAL APPLICATIONS

Interlocking guard for non locked mechanical screens offering free access (machines must achieve instant stop):

•Machine door or casting "open/closed" detection

•

•Control of mechanical screens used in addition to a safety light curtain

•Food & Beverage, Packaging, Machine Tool, Automotive and Textile.

Suitable for interfaces

up to

CATEGORY 3

per EN

C U® L US LISTED

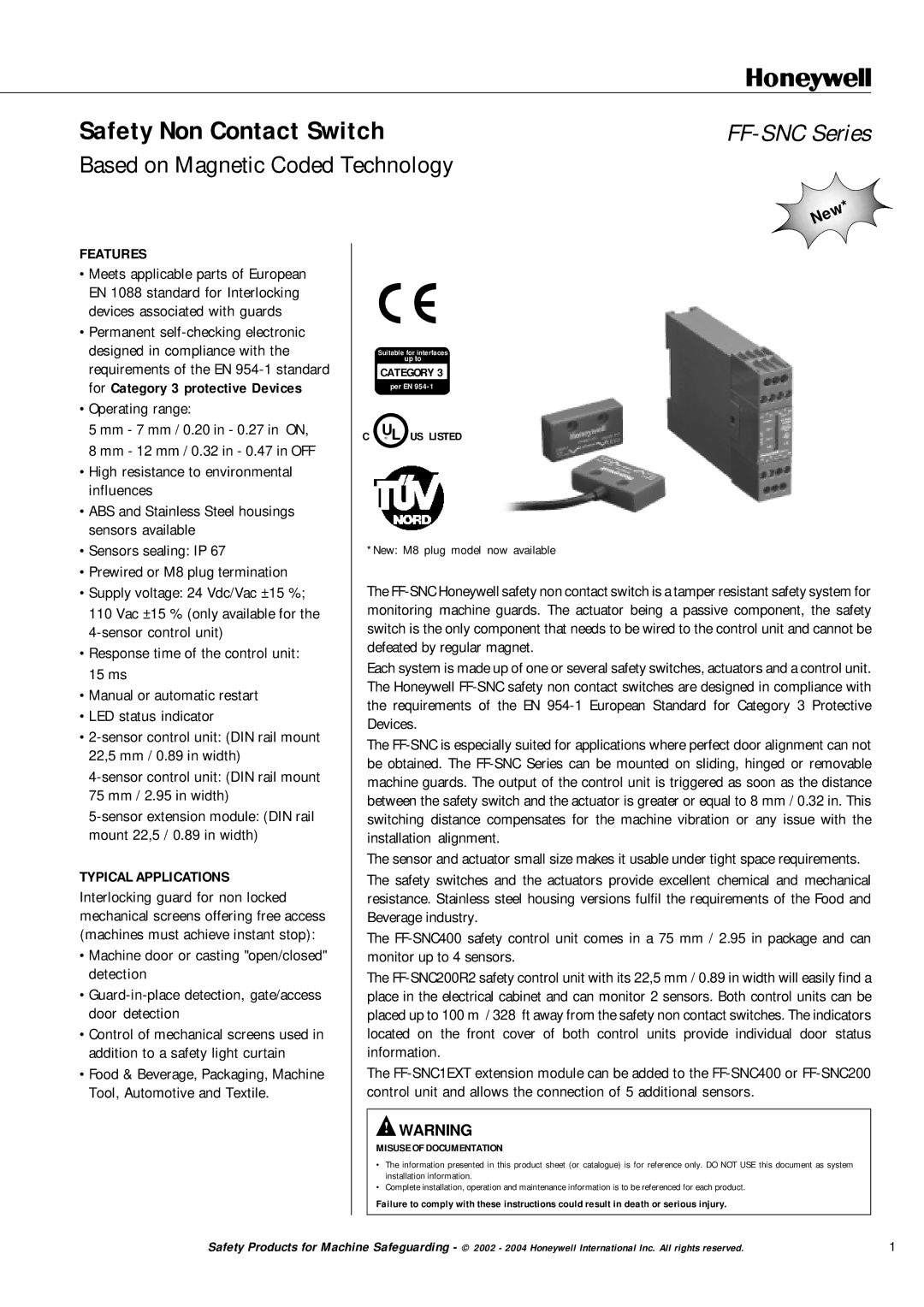

*New: M8 plug model now available

The

Each system is made up of one or several safety switches, actuators and a control unit. The Honeywell

The

The sensor and actuator small size makes it usable under tight space requirements.

The safety switches and the actuators provide excellent chemical and mechanical resistance. Stainless steel housing versions fulfil the requirements of the Food and Beverage industry.

The

The

The

!WARNING

MISUSE OF DOCUMENTATION

•The information presented in this product sheet (or catalogue) is for reference only. DO NOT USE this document as system installation information.

•Complete installation, operation and maintenance information is to be referenced for each product.

Failure to comply with these instructions could result in death or serious injury.

Safety Products for Machine Safeguarding - © 2002 - 2004 Honeywell International Inc. All rights reserved. | 1 |