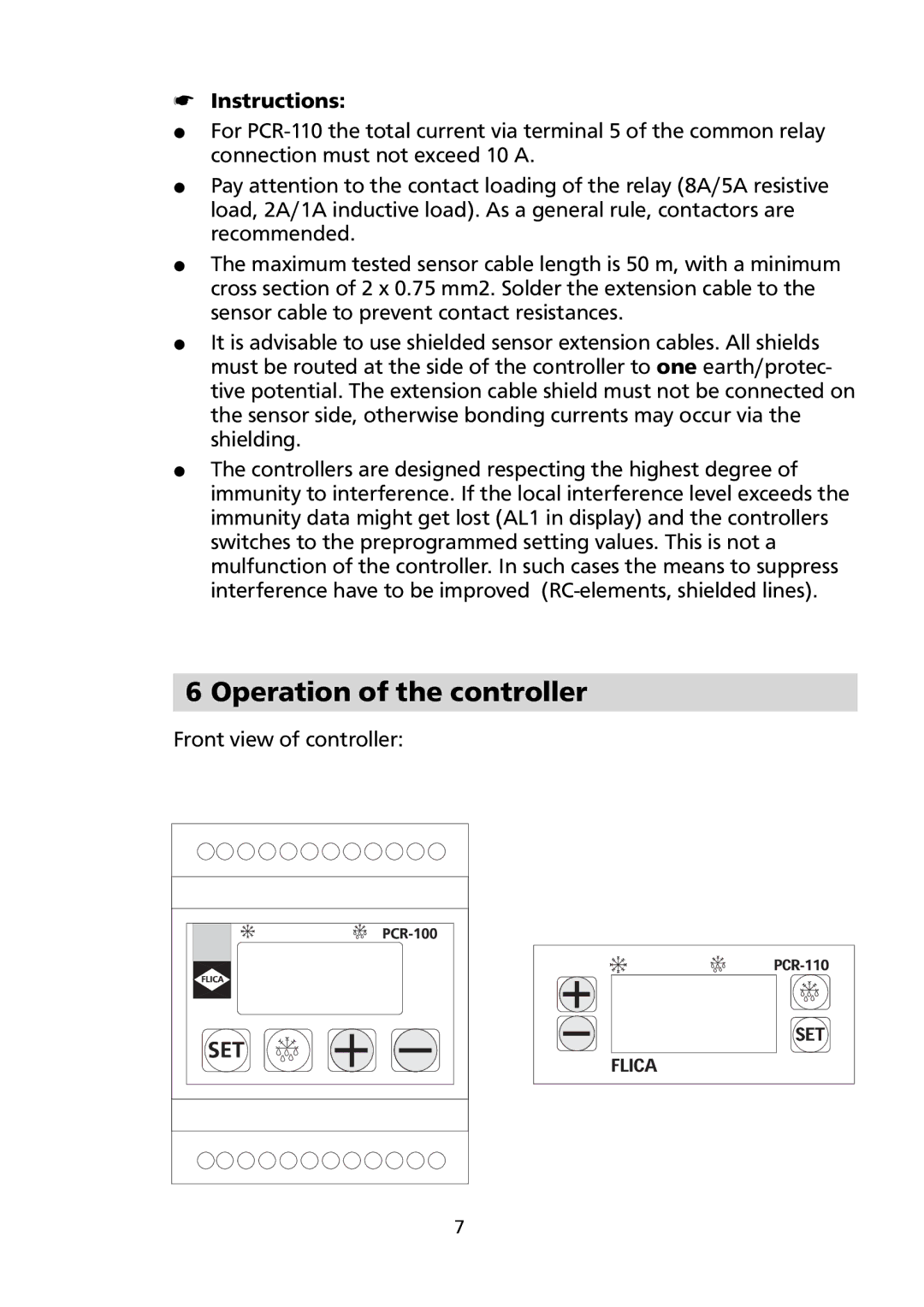

PCR-100, PCR-110 specifications

The Honeywell PCR-110 and PCR-100 are state-of-the-art portable gas detection instruments designed to meet the rigorous demands of industrial safety and environmental monitoring. These devices are part of Honeywell’s long-standing reputation for innovation in safety technology and are ideal for organizations that prioritize the health and safety of their workforce while complying with regulatory standards.The PCR-110 is specifically designed for multi-gas detection, capable of identifying a range of hazardous gases, including volatile organic compounds (VOCs), carbon monoxide, hydrogen sulfide, and methane. With its advanced sensor technology, the PCR-110 offers high sensitivity and responsiveness, providing real-time detection that is essential for prompt decision-making in hazardous situations. Furthermore, it features a user-friendly interface that allows for easy operation, ensuring that users can quickly access information and alerts.

On the other hand, the PCR-100, while similar in design, is optimized for specific applications and offers features tailored to particular industries and environments. Both models support a robust data logging capability, allowing users to store and analyze gas concentration trends over time, thus enhancing their understanding of potential risks.

A significant highlight of both models is their use of advanced wireless communication technology. The PCR-110 and PCR-100 can conveniently connect to Honeywell’s secure cloud-based platform. This connectivity enables real-time monitoring and remote access to data, facilitating efficient management and response strategies. Users can set thresholds for gas concentrations and receive immediate notifications should the levels exceed safe limits.

Durability is another critical characteristic of Honeywell’s gas detectors. Both models are constructed to withstand harsh environmental conditions, making them suitable for use in various industrial settings, including oil and gas, chemical manufacturing, and waste management. Their rugged design ensures that they can endure exposure to dust, moisture, and extreme temperatures, ensuring reliable performance in the field.

Equipped with long-lasting battery life, both the PCR-110 and PCR-100 maximize operational uptime. Moreover, their lightweight and compact form factor ensures that they can be easily carried or mounted, offering versatility in any work environment.

In conclusion, the Honeywell PCR-110 and PCR-100 provide a comprehensive solution for gas detection across multiple sectors, combining advanced technologies, durable construction, and user-focused design. Their capabilities empower organizations to enhance safety protocols and effectively manage gas-related risks, ultimately fostering a safer working environment.