Using the Drilling Template.

- To trace the positions of the holes on the left- hand side of the panel, align the drilling tem- plate to the top left side of the panel using the lines traced on the extremities as a reference. - To trace the positions of the holes on the

- Use an appropriately sized router to mill the holes for the two hinges, the rubber plug and the magnet.

Mounding the Parts onto the Wooden Panel (Door).

- Insert the hinges into the holes (the movable part of the hinge must be positioned facing away from the panel) and fasten them with the 4 type A screws.

- Insert the magnet into the top hole on the opposite side of the hinges and fasten it with the two type B screws.

- Insert the rubber plug into the bottom hole. The panel is now ready to be mounted onto the machine.

Mounting the Panel into the machine. Insert the nib of the hinge (indicated by the arrow in fig. 2) into the hole for the hinge and push the panel towards the front of the machine. Fasten the two hinges with the type D screws.

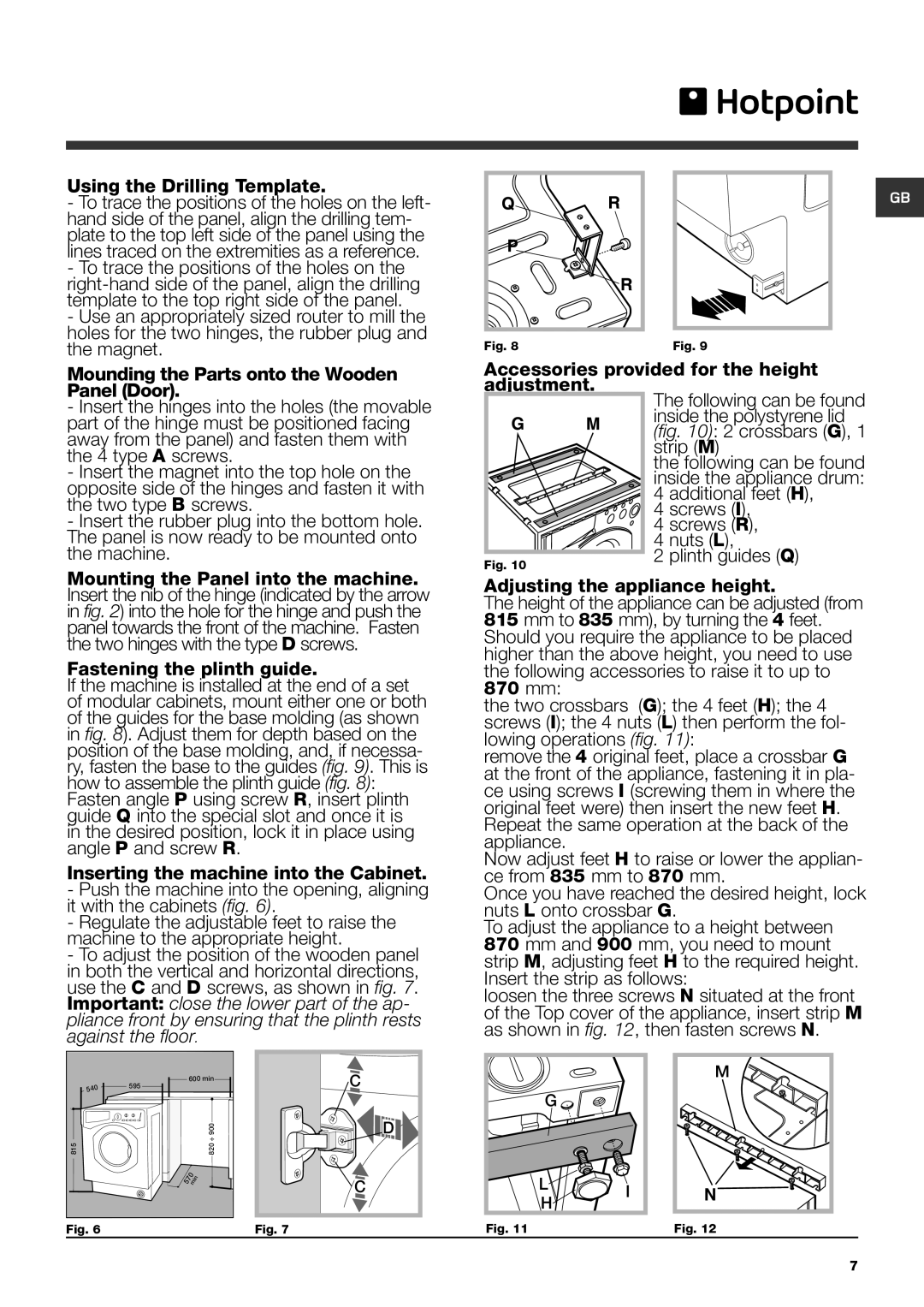

Fastening the plinth guide.

If the machine is installed at the end of a set of modular cabinets, mount either one or both of the guides for the base molding (as shown in fig. 8). Adjust them for depth based on the position of the base molding, and, if necessa- ry, fasten the base to the guides (fig. 9). This is how to assemble the plinth guide (fig. 8): Fasten angle P using screw R, insert plinth guide Q into the special slot and once it is in the desired position, lock it in place using angle P and screw R.

Inserting the machine into the Cabinet. - Push the machine into the opening, aligning it with the cabinets (fig. 6).

- Regulate the adjustable feet to raise the machine to the appropriate height.

- To adjust the position of the wooden panel in both the vertical and horizontal directions, use the C and D screws, as shown in fig. 7. Important: close the lower part of the ap- pliance front by ensuring that the plinth rests against the floor.

GB

Fig. 8 | Fig. 9 |

Accessories provided for the height adjustment.

The following can be found inside the polystyrene lid (fig. 10): 2 crossbars (G), 1 strip (M)

the following can be found inside the appliance drum:

4 additional feet (H),

4 screws (I),

4 screws (R),

4 nuts (L),

2 plinth guides (Q)

Adjusting the appliance height.

The height of the appliance can be adjusted (from 815 mm to 835 mm), by turning the 4 feet. Should you require the appliance to be placed higher than the above height, you need to use the following accessories to raise it to up to

870 mm:

the two crossbars (G); the 4 feet (H); the 4 screws (I); the 4 nuts (L) then perform the fol- lowing operations (fig. 11):

remove the 4 original feet, place a crossbar G at the front of the appliance, fastening it in pla- ce using screws I (screwing them in where the original feet were) then insert the new feet H.

Repeat the same operation at the back of the appliance.

Now adjust feet H to raise or lower the applian- ce from 835 mm to 870 mm.

Once you have reached the desired height, lock nuts L onto crossbar G.

To adjust the appliance to a height between 870 mm and 900 mm, you need to mount strip M, adjusting feet H to the required height. Insert the strip as follows:

loosen the three screws N situated at the front of the Top cover of the appliance, insert strip M as shown in fig. 12, then fasten screws N.

| 600 min | ||

540 | 595 |

|

|

|

|

| |

581 |

|

| 900÷ 820 |

| 570 | mi | n |

|

| ||

Fig. 6

C |

D |

C |

Fig. 7

G |

| |

L | I | |

H | ||

|

Fig. 11

M |

Fig. 12

7