The image processing pipeline for HP Designjet T1100-series printers features a 40GB hard disk drive. This allows in-printer image processing to be segmented into three stages that can run independently and simultaneously:

•parsing and building an Object List;

•rendering and storing a Virtual Page;

•composing and printing a page.

With this architecture, HP Designjet T1100-series printers can process up to three different jobs at the same time to deliver high printing productivity for workgroups.

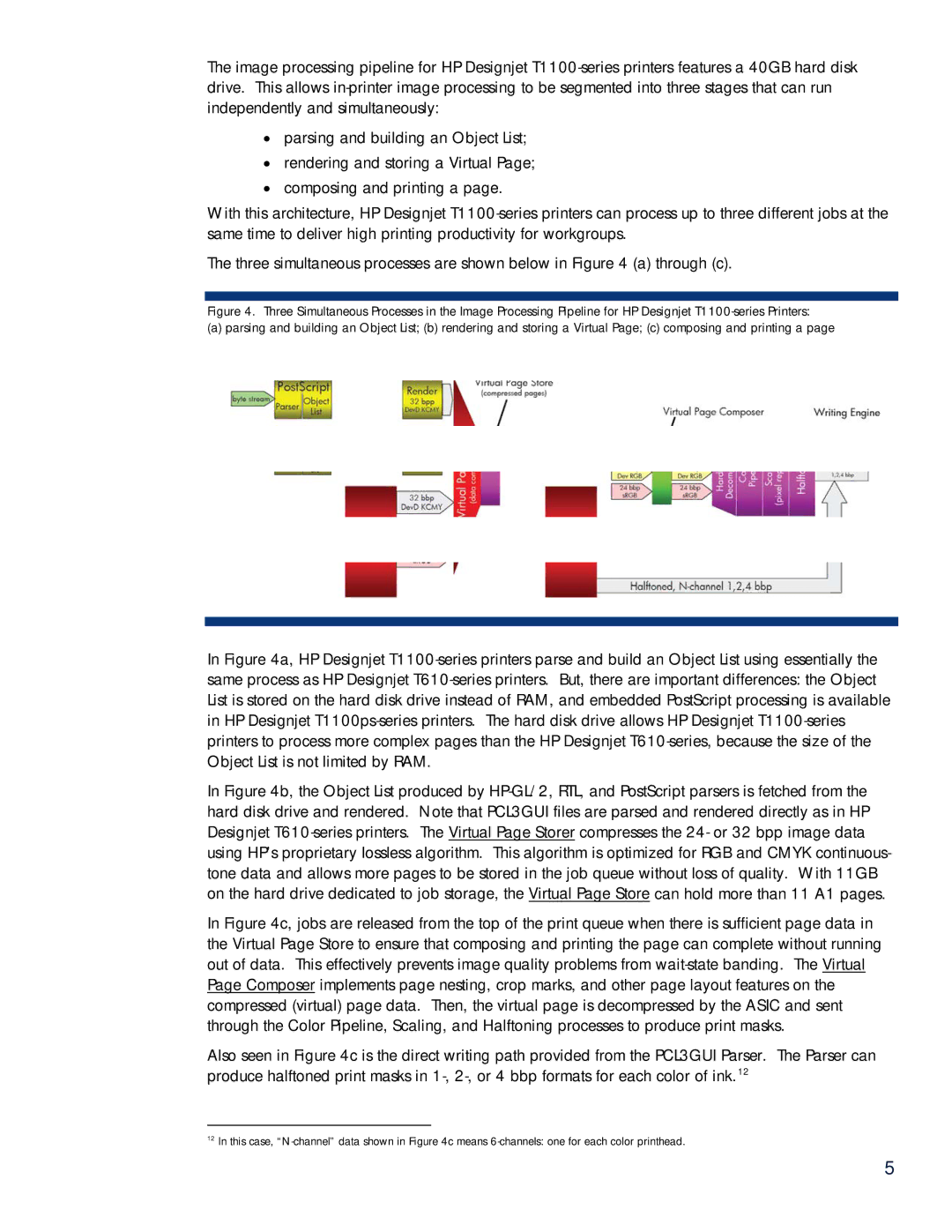

The three simultaneous processes are shown below in Figure 4 (a) through (c).

Figure 4. Three Simultaneous Processes in the Image Processing Pipeline for HP Designjet T1100-series Printers:

(a) parsing and building an Object List; (b) rendering and storing a Virtual Page; (c) composing and printing a page

In Figure 4a, HP Designjet T1100-series printers parse and build an Object List using essentially the same process as HP Designjet T610-series printers. But, there are important differences: the Object List is stored on the hard disk drive instead of RAM, and embedded PostScript processing is available in HP Designjet T1100ps-series printers. The hard disk drive allows HP Designjet T1100-series printers to process more complex pages than the HP Designjet T610-series, because the size of the Object List is not limited by RAM.

In Figure 4b, the Object List produced by HP-GL/2, RTL, and PostScript parsers is fetched from the hard disk drive and rendered. Note that PCL3GUI files are parsed and rendered directly as in HP Designjet T610-series printers. The Virtual Page Storer compresses the 24- or 32 bpp image data using HP’s proprietary lossless algorithm. This algorithm is optimized for RGB and CMYK continuous- tone data and allows more pages to be stored in the job queue without loss of quality. With 11GB on the hard drive dedicated to job storage, the Virtual Page Store can hold more than 11 A1 pages.

In Figure 4c, jobs are released from the top of the print queue when there is sufficient page data in the Virtual Page Store to ensure that composing and printing the page can complete without running out of data. This effectively prevents image quality problems from wait-state banding. The Virtual Page Composer implements page nesting, crop marks, and other page layout features on the compressed (virtual) page data. Then, the virtual page is decompressed by the ASIC and sent through the Color Pipeline, Scaling, and Halftoning processes to produce print masks.

Also seen in Figure 4c is the direct writing path provided from the PCL3GUI Parser. The Parser can produce halftoned print masks in 1-, 2-, or 4 bbp formats for each color of ink.12

12In this case, “N-channel” data shown in Figure 4c means 6-channels: one for each color printhead.