MAINTENANCE

Muffler

The muffler is designed in order to reduce the noise level and to direct the exhaust

Cooling system

To maintain as low an operating temperature as possible the power cutter is equipped with a cooling system.

gases away from the opera- tor. The exhaust gases are hot and can contain sparks, which may cause fire if directed against dry and combustible material.

Never use a saw with a clogged or defective muffler.

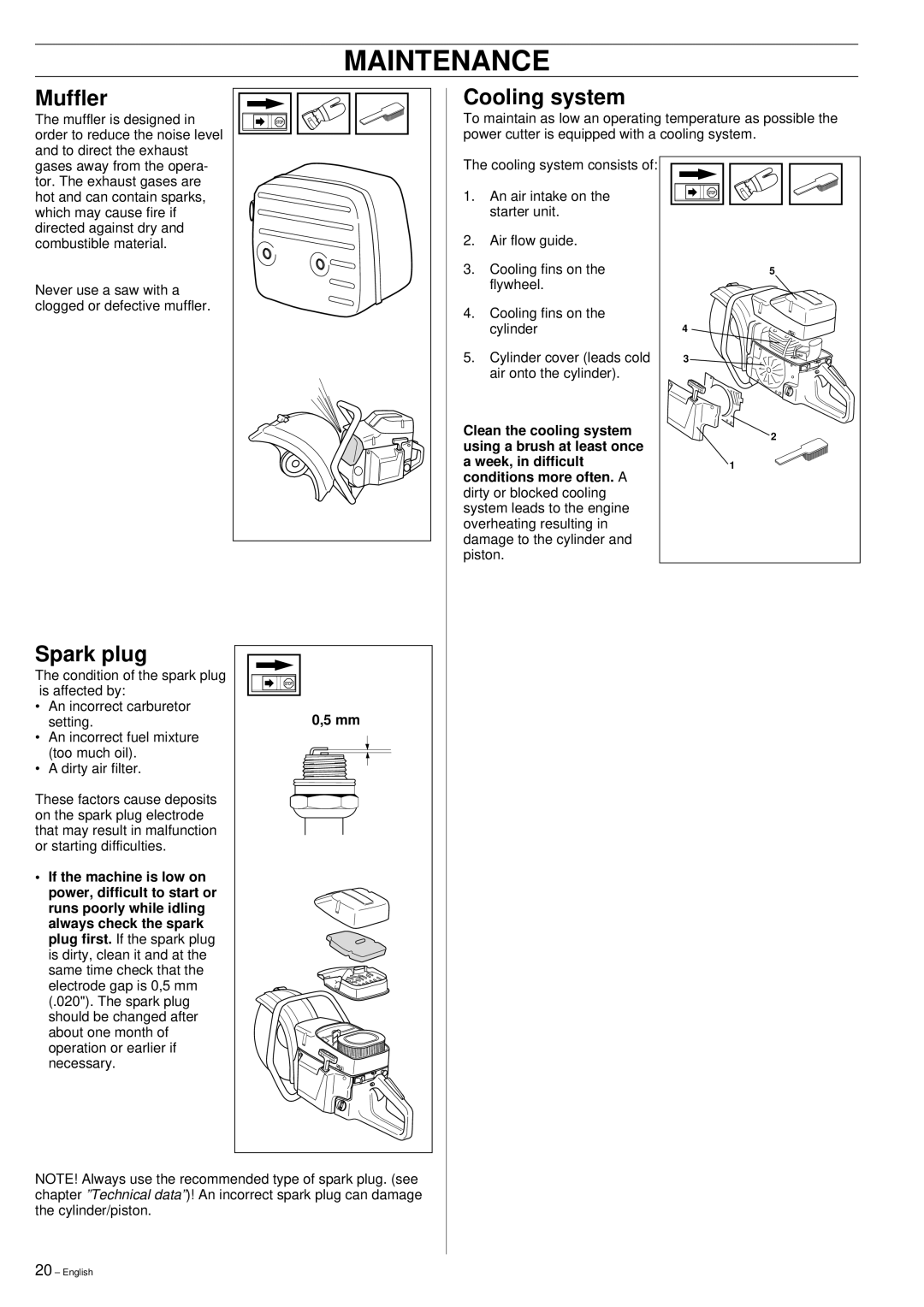

The cooling system consists of:

1.An air intake on the starter unit.

2.Air flow guide.

3.Cooling fins on the flywheel.

4.Cooling fins on the cylinder

5.Cylinder cover (leads cold air onto the cylinder).

Clean the cooling system using a brush at least once a week, in difficult conditions more often. A dirty or blocked cooling system leads to the engine overheating resulting in damage to the cylinder and piston.

5 |

4 |

3 |

2 |

1 |

Spark plug

The condition of the spark plug is affected by:

•An incorrect carburetor setting.

•An incorrect fuel mixture (too much oil).

•A dirty air filter.

These factors cause deposits on the spark plug electrode that may result in malfunction or starting difficulties.

•If the machine is low on power, difficult to start or runs poorly while idling always check the spark plug first. If the spark plug is dirty, clean it and at the same time check that the electrode gap is 0,5 mm (.020"). The spark plug should be changed after about one month of operation or earlier if necessary.

0,5 mm |

NOTE! Always use the recommended type of spark plug. (see chapter ”Technical data”)! An incorrect spark plug can damage the cylinder/piston.

20 – English