394XP specifications

The Husqvarna 394XP is a powerful chainsaw designed for professional use, catering to the demands of loggers and forestry workers. Launched as part of Husqvarna's XP series, the 394XP offers a perfect blend of performance, durability, and ergonomic design, making it an outstanding choice for heavy-duty cutting tasks.One of the standout features of the 394XP is its robust engine. It is equipped with a 94 cc, two-stroke engine that delivers impressive power while maintaining efficient fuel consumption. This high-output engine ensures that users can tackle demanding jobs with ease, whether it’s felling large trees or processing timber. The chainsaw also features a high chain speed, which enhances cutting performance and efficiency.

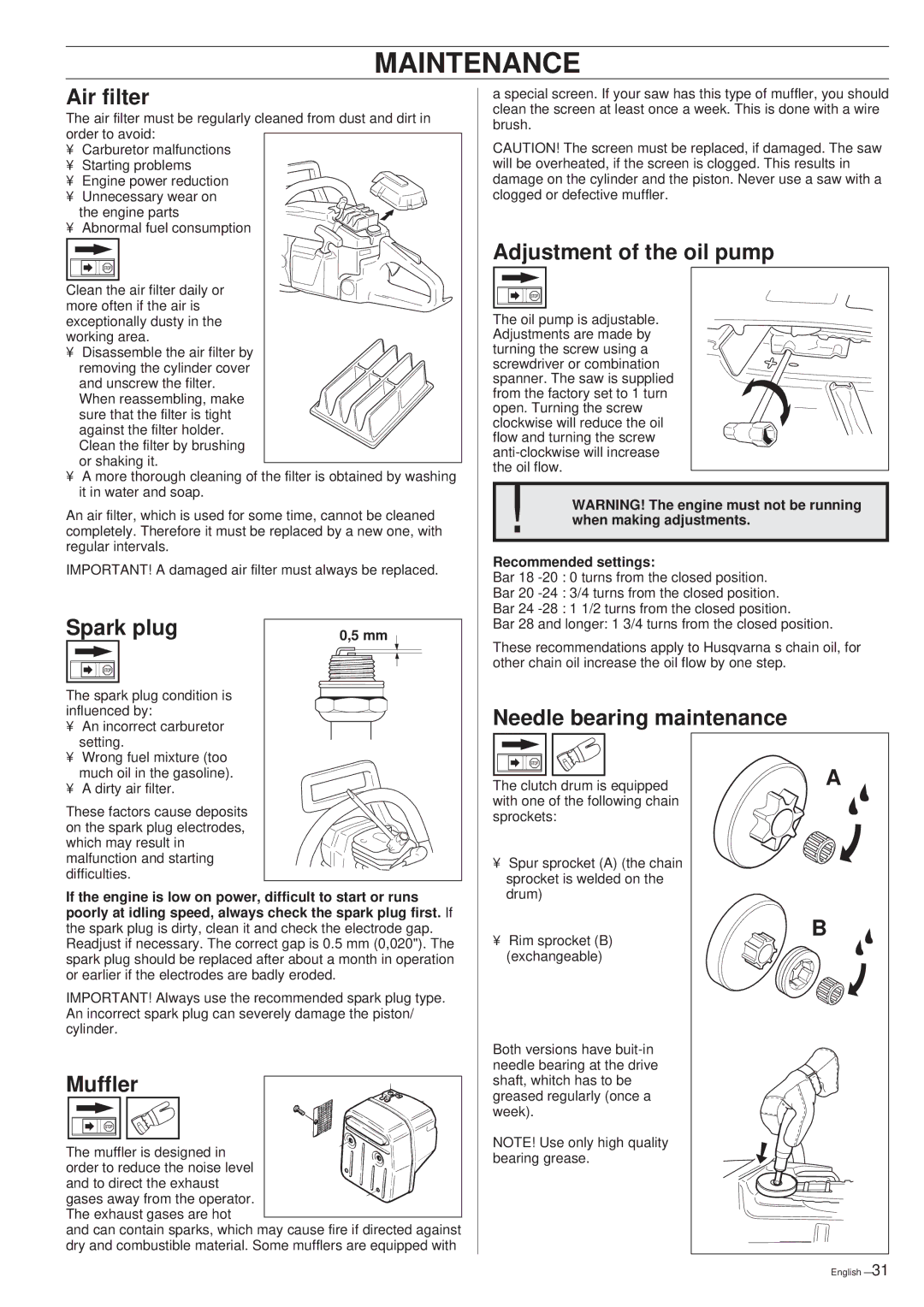

The 394XP is designed with user comfort in mind. It includes an adjustable oil pump, which allows for better control over oil flow and helps prolong the lifespan of the bar and chain. Additionally, the chainsaw boasts a lightweight design, which minimizes user fatigue during prolonged use. The ergonomic handle is designed to provide an optimal grip, ensuring maximum control and comfort during operation.

In terms of advanced technologies, the Husqvarna 394XP integrates the Air Injection system. This innovative technology helps to reduce wear and tear on the engine by separating larger dust and debris particles before they reach the air filter. This results in less frequent maintenance, ensuring the chainsaw operates smoothly over extended periods. The chainsaw also features the LowVib® system that significantly reduces vibrations, further enhancing comfort and allowing for longer usage without strain.

The chainsaw is fitted with a durable, forged cutting chain that provides sharp and precise cuts. Coupled with a guide bar that is available in various lengths, users can choose the optimal configuration for their cutting needs. The quick-release air filter makes maintenance simpler and faster, ensuring that the saw remains in peak condition.

In summary, the Husqvarna 394XP stands out in the world of professional chainsaws due to its exceptional power, innovative technologies, and user-centric design. It offers reliability and efficiency, making it an essential tool for anyone in the forestry and logging industries. Whether faced with the toughest cutting tasks or everyday maintenance work, the 394XP is engineered to perform at the highest level, empowering users to accomplish their work quickly and effectively.