GENERAL SAFETY PRECAUTIONS

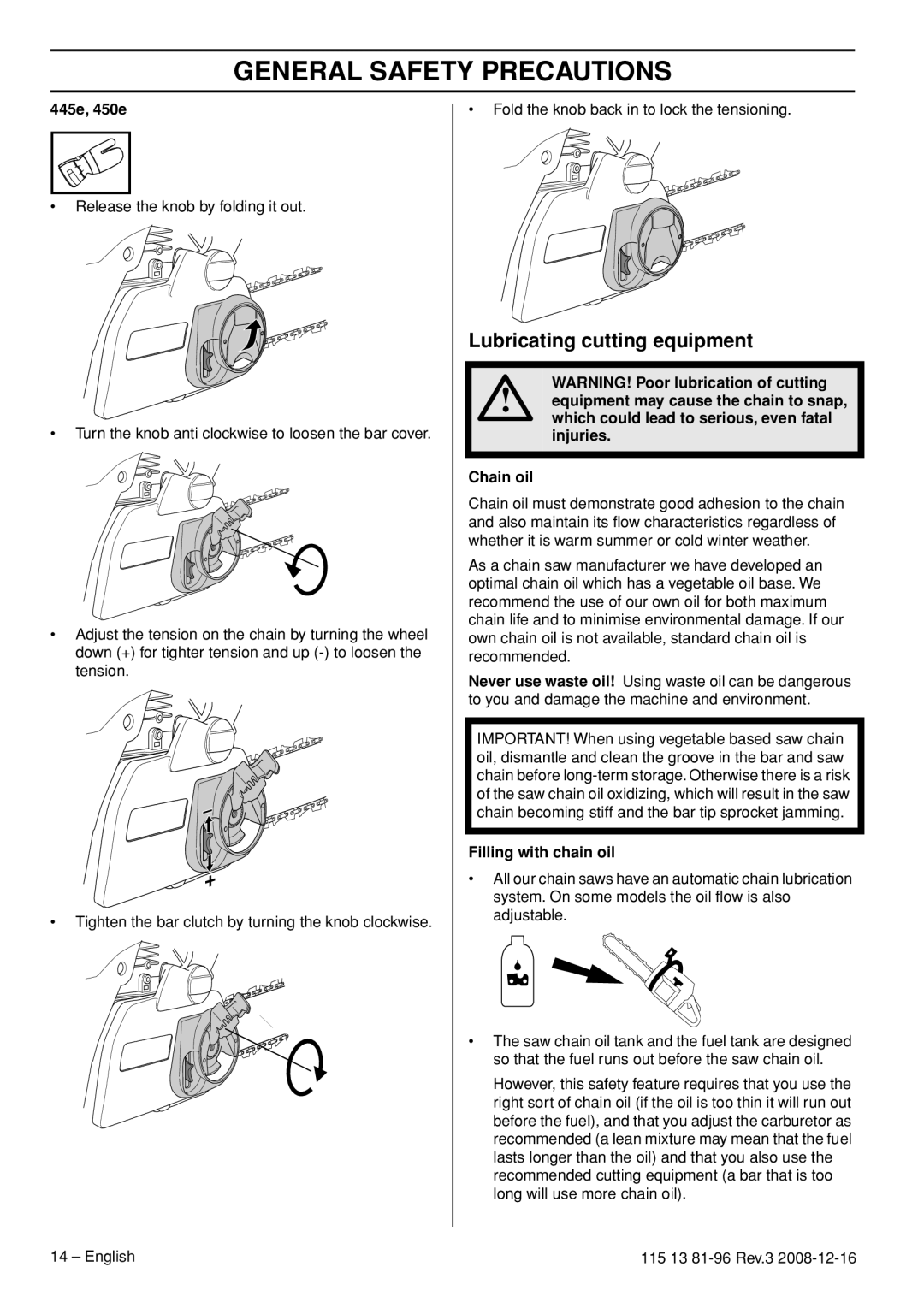

445e, 450e

•Release the knob by folding it out.

•Turn the knob anti clockwise to loosen the bar cover.

•Adjust the tension on the chain by turning the wheel down (+) for tighter tension and up

•Tighten the bar clutch by turning the knob clockwise.

•Fold the knob back in to lock the tensioning.

Lubricating cutting equipment

WARNING! Poor lubrication of cutting ! equipment may cause the chain to snap,

which could lead to serious, even fatal injuries.

Chain oil

Chain oil must demonstrate good adhesion to the chain and also maintain its flow characteristics regardless of whether it is warm summer or cold winter weather.

As a chain saw manufacturer we have developed an optimal chain oil which has a vegetable oil base. We recommend the use of our own oil for both maximum chain life and to minimise environmental damage. If our own chain oil is not available, standard chain oil is recommended.

Never use waste oil! Using waste oil can be dangerous to you and damage the machine and environment.

IMPORTANT! When using vegetable based saw chain oil, dismantle and clean the groove in the bar and saw chain before

Filling with chain oil

•All our chain saws have an automatic chain lubrication system. On some models the oil flow is also adjustable.

•The saw chain oil tank and the fuel tank are designed so that the fuel runs out before the saw chain oil.

However, this safety feature requires that you use the right sort of chain oil (if the oil is too thin it will run out before the fuel), and that you adjust the carburetor as recommended (a lean mixture may mean that the fuel lasts longer than the oil) and that you also use the recommended cutting equipment (a bar that is too long will use more chain oil).

14 – English | 115 13 |