DXR-310 specifications

The Husqvarna DXR-310 is a state-of-the-art remote-controlled demolition robot designed for various construction and demolition tasks. With an emphasis on versatility and efficiency, this robust machine stands out in the crowded landscape of demolition equipment. It is specifically engineered to tackle challenging environments while offering operators a high level of safety and control.One of the standout features of the DXR-310 is its powerful hydraulic system, which allows for exceptional performance even in the most demanding applications. With an output of 12.5 kW, it can handle various attachments effectively, enabling it to perform a wide array of tasks, from crushing and breaking to lifting and demolition. Its compact size and lightweight design make it easy to maneuver, which is particularly beneficial in confined spaces, such as renovation projects or urban environments.

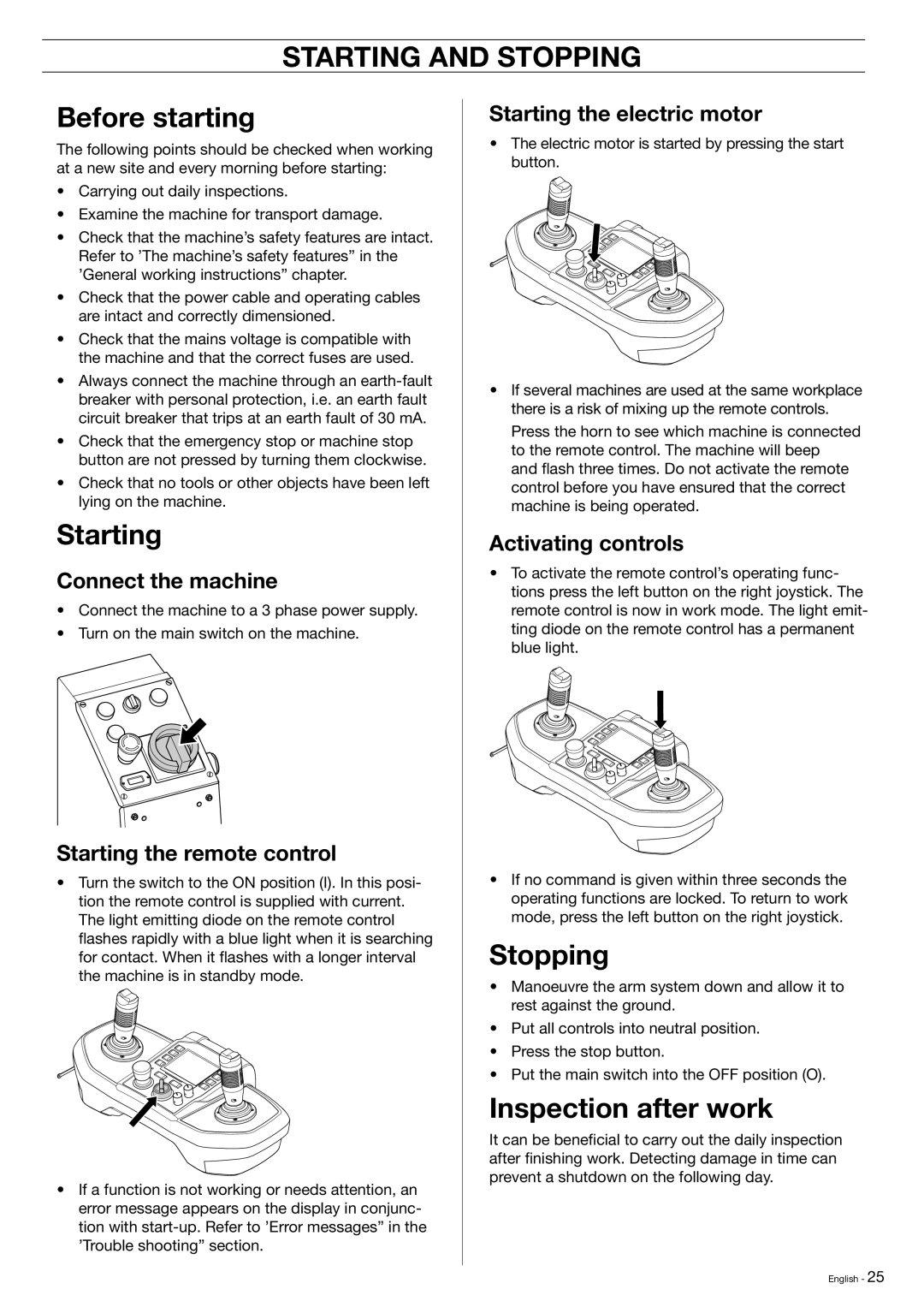

The DXR-310 is equipped with a user-friendly control system that facilitates precise operation from a distance. The ergonomic remote control is intuitive, allowing the operator to execute complex commands with ease, enhancing overall productivity. This feature is vital, especially in situations where operator safety is paramount, as it enables them to maintain a safe distance from potential hazards.

Another notable characteristic is the robot's durability and reliability. The chassis and components are designed to withstand harsh working conditions, ensuring long-term performance. The robust build minimizes downtime, enhancing overall efficiency on job sites.

The Husqvarna DXR-310 also integrates advanced technology to optimize its functionality. It is compatible with a range of attachments, including hydraulic breakers, crushers, and grapples, making it highly adaptable to various tasks. Additionally, the robot is designed with a unique suspension system that improves stability and ground contact, ensuring reliable operation on uneven surfaces.

In terms of maintenance, the DXR-310 is designed to be user-friendly, with accessible components that simplify routine checks and repairs. This commitment to easy maintenance contributes to reduced operational costs over time.

In conclusion, the Husqvarna DXR-310 demolition robot combines power, versatility, and safety into a single machine. Its advanced hydraulic system, user-friendly controls, and adaptability make it ideal for a wide range of demolition applications. The robust design and maintenance-friendly features further enhance its appeal to contractors looking for efficient solutions in the construction industry.