SERVICE AND ADJUSTMENTS

TO ADJUST ATTACHMENT CLUTCH (See Fig. 24)

The electric clutch should provide years of service. The clutch has a

•Make sure attachment clutch and ignition switches are in “OFF” position.

•Adjust the three nylon locknuts until space between clutch plate and rotor measures .012" at all three slot locations cut in side of brake plate.

NOTE: After installing a new electric clutch, run tractor at full throttle and engage and disengage electric clutch 10 cycles to wear in clutch plate.

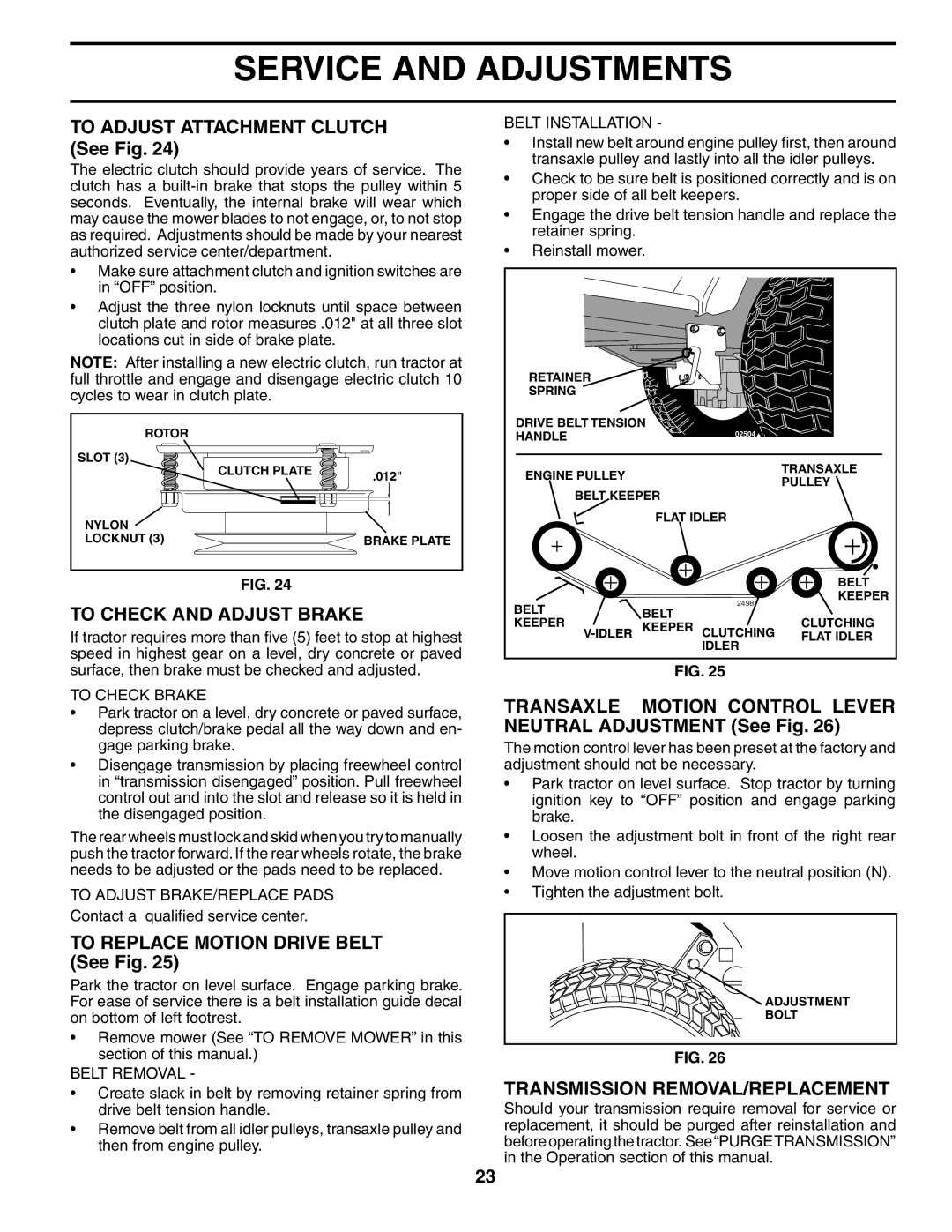

BELT INSTALLATION -

•Install new belt around engine pulley first, then around transaxle pulley and lastly into all the idler pulleys.

•Check to be sure belt is positioned correctly and is on proper side of all belt keepers.

•Engage the drive belt tension handle and replace the retainer spring.

• | Reinstall mower. |

| RETAINER |

| SPRING |

| DRIVE BELT TENSION |

ROTOR

SLOT (3)

CLUTCH PLATE

NYLON

LOCKNUT (3)

00751

.012"

BRAKE PLATE

HANDLE | 02504 | |

| ||

ENGINE PULLEY | TRANSAXLE | |

PULLEY | ||

BELT KEEPER | ||

| ||

FLAT IDLER |

|

FIG. 24

TO CHECK AND ADJUST BRAKE

If tractor requires more than five (5) feet to stop at highest speed in highest gear on a level, dry concrete or paved surface, then brake must be checked and adjusted.

TO CHECK BRAKE

•Park tractor on a level, dry concrete or paved surface, depress clutch/brake pedal all the way down and en- gage parking brake.

•Disengage transmission by placing freewheel control in “transmission disengaged” position. Pull freewheel control out and into the slot and release so it is held in the disengaged position.

The rear wheels must lock and skid when you try to manually push the tractor forward. If the rear wheels rotate, the brake needs to be adjusted or the pads need to be replaced.

TO ADJUST BRAKE/REPLACE PADS

Contact a qualified service center.

TO REPLACE MOTION DRIVE BELT (See Fig. 25)

Park the tractor on level surface. Engage parking brake. For ease of service there is a belt installation guide decal on bottom of left footrest.

•Remove mower (See “TO REMOVE MOWER” in this section of this manual.)

BELT REMOVAL -

•Create slack in belt by removing retainer spring from drive belt tension handle.

•Remove belt from all idler pulleys, transaxle pulley and then from engine pulley.

|

| BELT | |

BELT | 2498 | KEEPER | |

| |||

BELT |

| ||

KEEPER | CLUTCHING | ||

KEEPER CLUTCHING | |||

FLAT IDLER | |||

| IDLER |

|

FIG. 25

TRANSAXLE MOTION CONTROL LEVER NEUTRAL ADJUSTMENT (See Fig. 26)

The motion control lever has been preset at the factory and adjustment should not be necessary.

•Park tractor on level surface. Stop tractor by turning ignition key to “OFF” position and engage parking brake.

•Loosen the adjustment bolt in front of the right rear wheel.

•Move motion control lever to the neutral position (N).

•Tighten the adjustment bolt.

ADJUSTMENT

BOLT

FIG. 26

TRANSMISSION REMOVAL/REPLACEMENT

Should your transmission require removal for service or replacement, it should be purged after reinstallation and before operating the tractor. See“PURGETRANSMISSION” in the Operation section of this manual.

23