SAFETY INSTRUCTIONS

Cutting

WARNING! The safety distance for the power

!cutter is 15 metres. You are responsible to ensure that animals and onlookers are not within the working area. Do not start cutting until the working area is clear and you are standing firmly.

General

•Start cutting with the machine running at maximum speed.

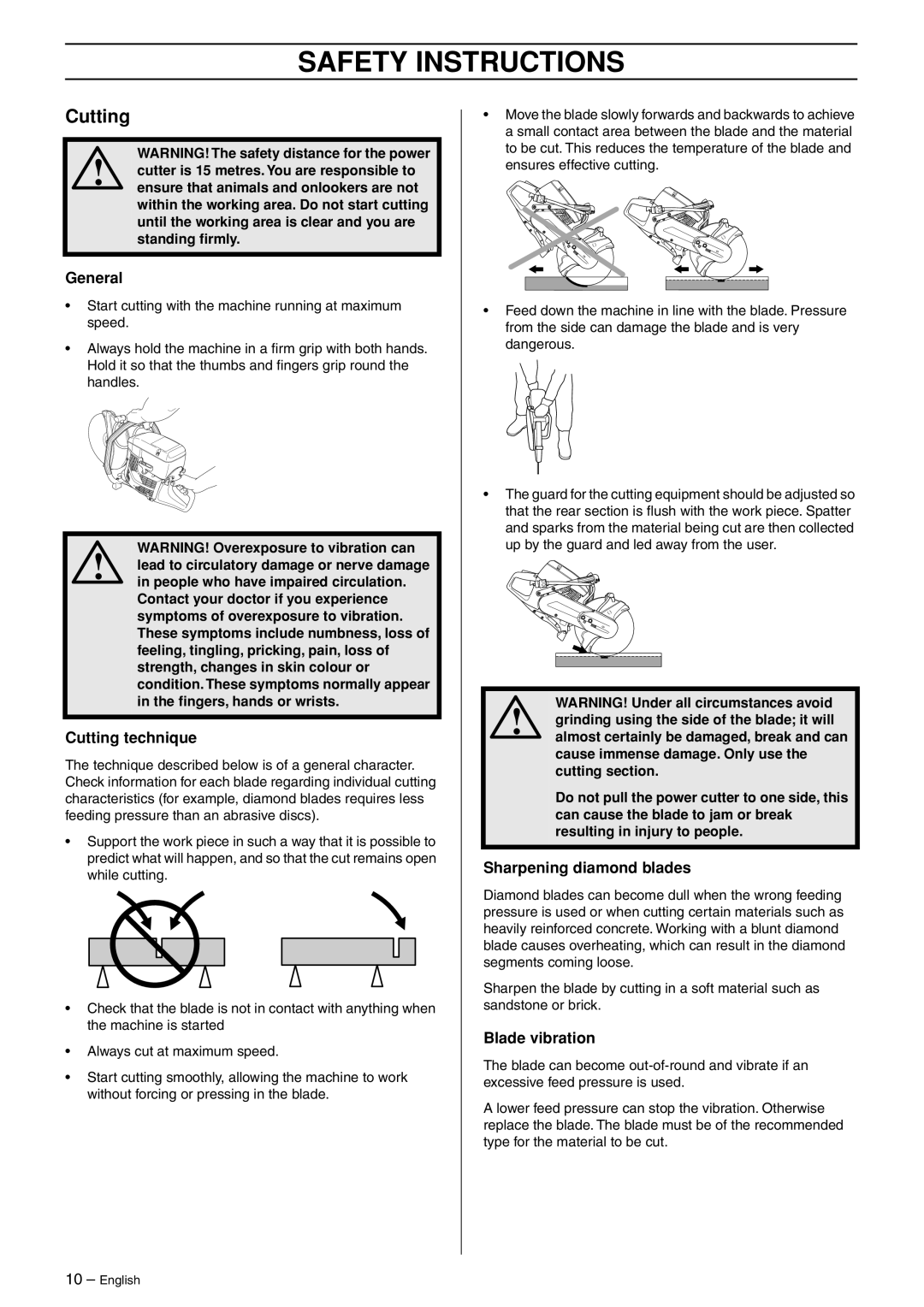

•Always hold the machine in a firm grip with both hands. Hold it so that the thumbs and fingers grip round the handles.

WARNING! Overexposure to vibration can

!lead to circulatory damage or nerve damage in people who have impaired circulation. Contact your doctor if you experience symptoms of overexposure to vibration. These symptoms include numbness, loss of feeling, tingling, pricking, pain, loss of strength, changes in skin colour or condition. These symptoms normally appear in the fingers, hands or wrists.

Cutting technique

The technique described below is of a general character. Check information for each blade regarding individual cutting characteristics (for example, diamond blades requires less feeding pressure than an abrasive discs).

•Support the work piece in such a way that it is possible to predict what will happen, and so that the cut remains open while cutting.

•Check that the blade is not in contact with anything when the machine is started

•Always cut at maximum speed.

•Start cutting smoothly, allowing the machine to work without forcing or pressing in the blade.

•Move the blade slowly forwards and backwards to achieve a small contact area between the blade and the material to be cut. This reduces the temperature of the blade and ensures effective cutting.

•Feed down the machine in line with the blade. Pressure from the side can damage the blade and is very dangerous.

•The guard for the cutting equipment should be adjusted so that the rear section is flush with the work piece. Spatter and sparks from the material being cut are then collected up by the guard and led away from the user.

WARNING! Under all circumstances avoid

!grinding using the side of the blade; it will almost certainly be damaged, break and can cause immense damage. Only use the cutting section.

Do not pull the power cutter to one side, this can cause the blade to jam or break resulting in injury to people.

Sharpening diamond blades

Diamond blades can become dull when the wrong feeding pressure is used or when cutting certain materials such as heavily reinforced concrete. Working with a blunt diamond blade causes overheating, which can result in the diamond segments coming loose.

Sharpen the blade by cutting in a soft material such as sandstone or brick.

Blade vibration

The blade can become

A lower feed pressure can stop the vibration. Otherwise replace the blade. The blade must be of the recommended type for the material to be cut.

10 – English