Overservicing

Overservicing occurs when an air filter element is removed for cleaning or replacement before it is necessary. Each time the filter is removed a small amount of dirt and dust could fall in the intake system. This accumulated dirt can cause a dusted engine. It only takes a few grams of ingested dirt over the normal service life of an engine to cause a dusted engine.

Do not clean element, replace with a new element only. Cleaning used air filter elements, through improper cleaning procedures, can get dust on the inside of the filter causing dirt ingestion and engine failure.

It is important to note that whenever an air filter element is cleaned by any method, the person or company performing the cleaning assumes responsibility for the integrity of the filter from then on. The warranty for air filters expires upon cleaning or servicing in any manner because the condition of the filter after servicing is completely out of their control. Therefore, on a dust ingested engine failure, there will be no warranty consideration if the air filter element has been cleaned or serviced in any manner.

A partially dirty air filter element works better than a new element. Therefore, a dirty filter element is not bad for the engine unless it is excessively restricting the air flow and engine performance is affected. The reason is simple. The media in the filter must be porous to allow air to pass through it. When dirty air passes through the filter, the dirt plugs some of the holes in the media and actually acts as part of the filter media. When the next round of dirt enters, the first dirt helps filter out even smaller particles making the filter more efficient at stopping dirt from entering the engine. This is referred to as barrier filtration.

Of course, at some point the filter media becomes too clogged to allow air to pass.

The mowing conditions will determine the frequency of air filter element changing.

General engine maintenance

Detailed instructions and recommendations for

Belts

Inspect belts frequently for wear and serviceability. Replace a belt that shows signs of severe cuts, tears, separation, weather checking and cracking, or burns caused by slipping. Slight raveling of belt covering does not indicate failure, trim ravelings with a sharp knife.

WARNING: If the pump belt fails, loss of control will occur especially when operating on a slope. If you lose steering control while operating the machine, place the steering

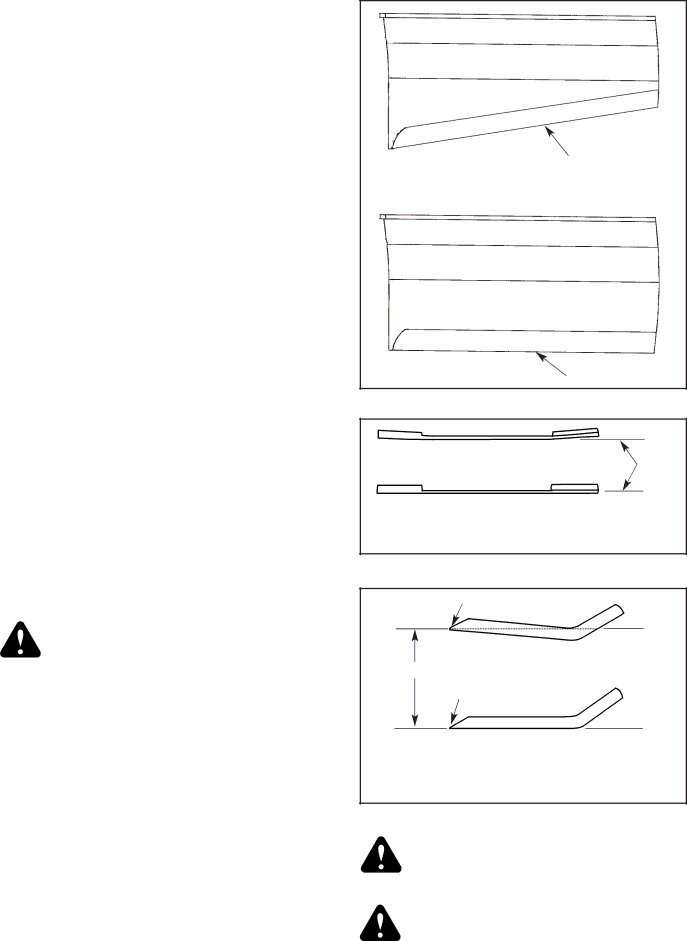

Resharpening Pattern

Do not sharpen to original pattern (below).

It is easier to get a straight cutting edge following the resharpening pattern shown above.

Original Edge

Figure |

Warped Blade (Replace) |

Cutting |

Plane |

Straight Blade |

Comparison of Warped and Straight Blades |

Figure |

Cutting Edge

Twisted Blade Edge

control levers in the park brake position immediately. Inspect the machine and involve your Hustler dealer to resolve the problem before continuing to operate.

Cutting Plane

(Replace)

Inspect the belt pulley grooves and flanges for wear. A new belt, or one in good condition, should never run against the bottom of the groove. Replace the pulley when this is the case, otherwise belt will lose power and slip excessively.

Never pry a belt to get it on a pulley as this will cut or damage the fibers of the belt covering.

Keep oil and grease away from belts, and never use belt dressings. Any of these will destroy the belt composition in a very short time.

Mower blade maintenance

Check the mower blades daily, they are the key to power efficiency and well groomed turf. Keep them sharp, a dull blade will tear rather than cut the grass, leaving a brown ragged top on the grass within a few hours. A dull blade also requires more power from the engine.

Replace any blade which is bent, cracked or broken.

Cutting Edge

Straight Blade Edge

End view of blades, comparing twisted and straighten blades.

Figure

WARNING: Never attempt to straighten a bent blade by heating, or weld a cracked or broken blade as the blade may break and cause serious injury. Replace worn or damaged blades.

DANGER: Never work with blades while engine is running or deck clutch switch is engaged (on). Always place deck clutch switch in the disengaged position, place control levers in the park brake position and turn engine off and disconnect

22 | 107708_0808 |