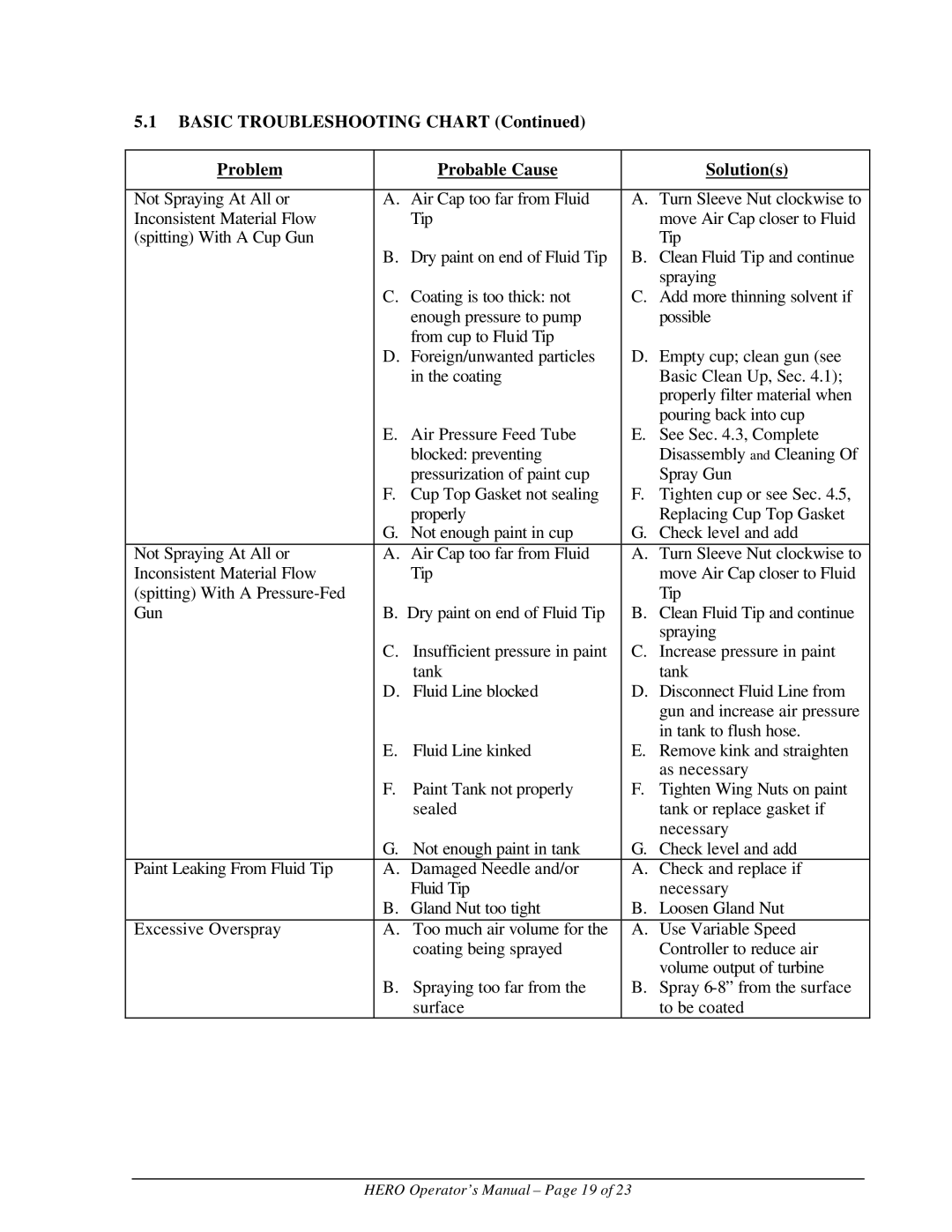

5.1BASIC TROUBLESHOOTING CHART (Continued)

Problem |

| Probable Cause |

| Solution(s) |

|

|

|

| |

Not Spraying At All or | A. | Air Cap too far from Fluid | A. Turn Sleeve Nut clockwise to | |

Inconsistent Material Flow |

| Tip |

| move Air Cap closer to Fluid |

(spitting) With A Cup Gun |

|

|

| Tip |

| B. | Dry paint on end of Fluid Tip | B. | Clean Fluid Tip and continue |

|

|

|

| spraying |

| C. | Coating is too thick: not | C. | Add more thinning solvent if |

|

| enough pressure to pump |

| possible |

|

| from cup to Fluid Tip |

|

|

| D. Foreign/unwanted particles | D. Empty cup; clean gun (see | ||

|

| in the coating |

| Basic Clean Up, Sec. 4.1); |

|

|

|

| properly filter material when |

|

|

|

| pouring back into cup |

| E. | Air Pressure Feed Tube | E. | See Sec. 4.3, Complete |

|

| blocked: preventing |

| Disassembly and Cleaning Of |

|

| pressurization of paint cup |

| Spray Gun |

| F. | Cup Top Gasket not sealing | F. | Tighten cup or see Sec. 4.5, |

|

| properly |

| Replacing Cup Top Gasket |

| G. | Not enough paint in cup | G. | Check level and add |

Not Spraying At All or | A. | Air Cap too far from Fluid | A. Turn Sleeve Nut clockwise to | |

Inconsistent Material Flow |

| Tip |

| move Air Cap closer to Fluid |

(spitting) With A |

|

|

| Tip |

Gun | B. Dry paint on end of Fluid Tip | B. | Clean Fluid Tip and continue | |

|

|

|

| spraying |

| C. | Insufficient pressure in paint | C. | Increase pressure in paint |

|

| tank |

| tank |

| D. | Fluid Line blocked | D. Disconnect Fluid Line from | |

|

|

|

| gun and increase air pressure |

|

|

|

| in tank to flush hose. |

| E. | Fluid Line kinked | E. | Remove kink and straighten |

|

|

|

| as necessary |

| F. | Paint Tank not properly | F. | Tighten Wing Nuts on paint |

|

| sealed |

| tank or replace gasket if |

|

|

|

| necessary |

| G. Not enough paint in tank | G. | Check level and add | |

Paint Leaking From Fluid Tip | A. Damaged Needle and/or | A. Check and replace if | ||

|

| Fluid Tip |

| necessary |

| B. | Gland Nut too tight | B. | Loosen Gland Nut |

Excessive Overspray | A. | Too much air volume for the | A. Use Variable Speed | |

|

| coating being sprayed |

| Controller to reduce air |

|

|

|

| volume output of turbine |

| B. | Spraying too far from the | B. | Spray |

|

| surface |

| to be coated |

HERO Operator’s Manual – Page 19 of 23