DIAPHRAGM REPLACEMENT

Tools or Supplies Required

♦ | 1/4 Allan wrench | ♦ | ♦ | Torque Wrench | ♦ | 3/8” Open end wrench | |

|

|

|

|

|

|

|

|

♦ | 1/8 Allan wrench | ♦ | H.E.R.O. hydraulic oil | ♦ | Rags | ♦ | Drip / collection tray |

|

|

|

|

|

|

|

|

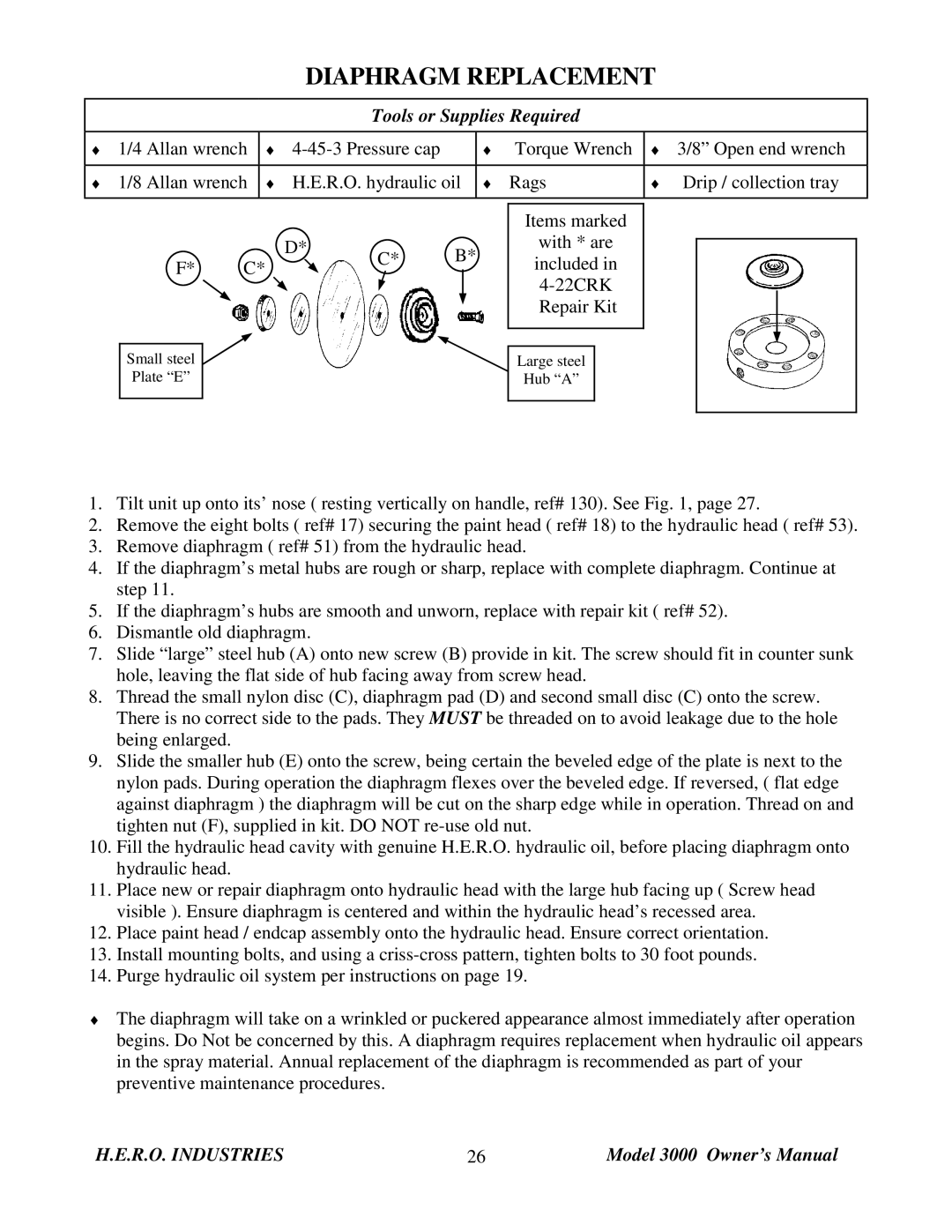

F* | C* | D* | C* | B* |

| ||||

|

|

|

Small steel ![]()

Plate “E”

Items marked

with * are

included in

Large steel

Hub “A”

1.Tilt unit up onto its’ nose ( resting vertically on handle, ref# 130). See Fig. 1, page 27.

2.Remove the eight bolts ( ref# 17) securing the paint head ( ref# 18) to the hydraulic head ( ref# 53).

3.Remove diaphragm ( ref# 51) from the hydraulic head.

4.If the diaphragm’s metal hubs are rough or sharp, replace with complete diaphragm. Continue at step 11.

5.If the diaphragm’s hubs are smooth and unworn, replace with repair kit ( ref# 52).

6.Dismantle old diaphragm.

7.Slide “large” steel hub (A) onto new screw (B) provide in kit. The screw should fit in counter sunk hole, leaving the flat side of hub facing away from screw head.

8.Thread the small nylon disc (C), diaphragm pad (D) and second small disc (C) onto the screw. There is no correct side to the pads. They MUST be threaded on to avoid leakage due to the hole being enlarged.

9.Slide the smaller hub (E) onto the screw, being certain the beveled edge of the plate is next to the nylon pads. During operation the diaphragm flexes over the beveled edge. If reversed, ( flat edge against diaphragm ) the diaphragm will be cut on the sharp edge while in operation. Thread on and tighten nut (F), supplied in kit. DO NOT

10.Fill the hydraulic head cavity with genuine H.E.R.O. hydraulic oil, before placing diaphragm onto hydraulic head.

11.Place new or repair diaphragm onto hydraulic head with the large hub facing up ( Screw head visible ). Ensure diaphragm is centered and within the hydraulic head’s recessed area.

12.Place paint head / endcap assembly onto the hydraulic head. Ensure correct orientation.

13.Install mounting bolts, and using a

14.Purge hydraulic oil system per instructions on page 19.

♦The diaphragm will take on a wrinkled or puckered appearance almost immediately after operation begins. Do Not be concerned by this. A diaphragm requires replacement when hydraulic oil appears in the spray material. Annual replacement of the diaphragm is recommended as part of your preventive maintenance procedures.

H.E.R.O. INDUSTRIES | 26 | Model 3000 Owner’s Manual |