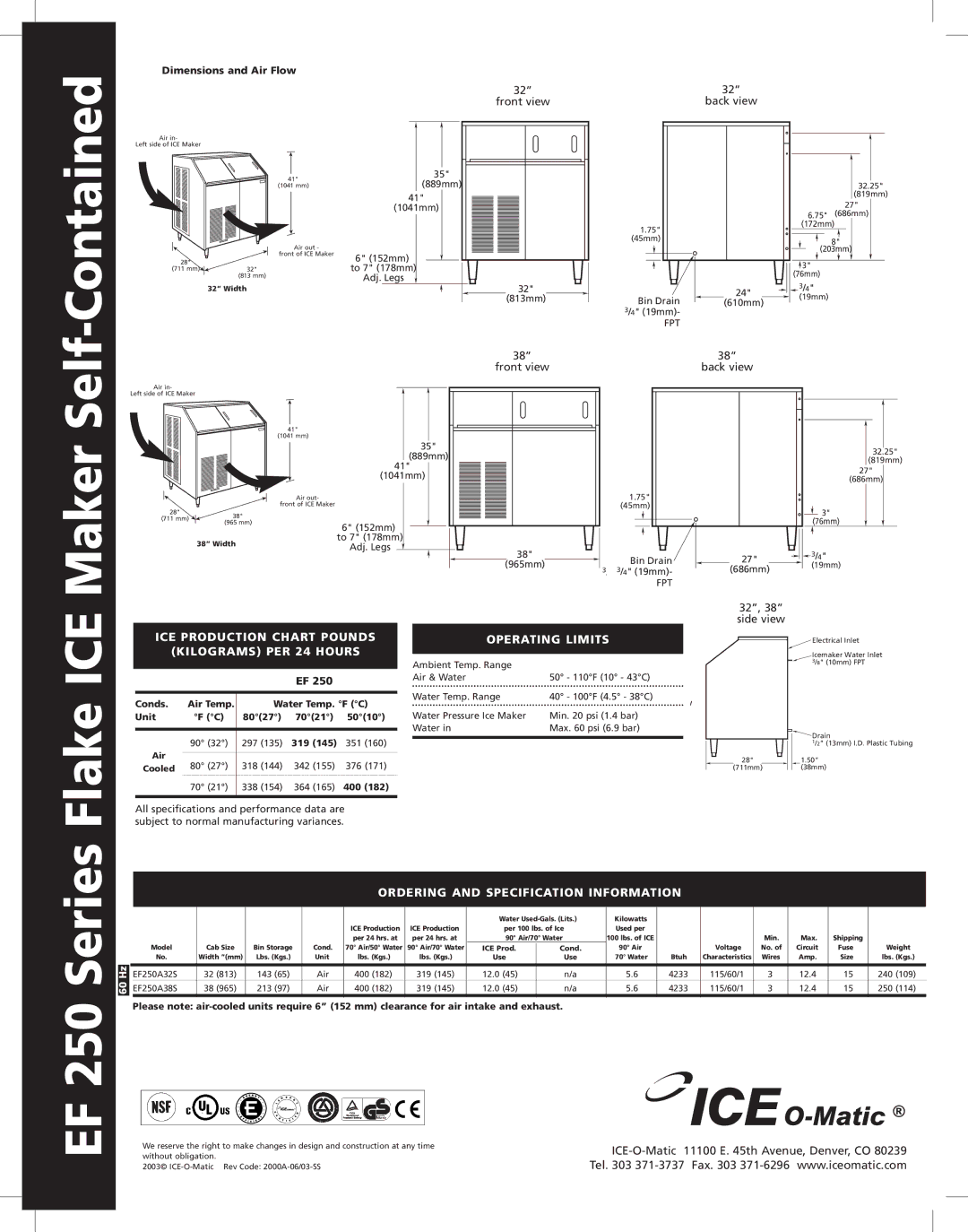

EF250 specifications

The Ice-O-Matic EF250 is a state-of-the-art ice maker renowned for its efficiency and reliability, making it an ideal choice for various commercial settings, including restaurants, hotels, and bars. Designed to cater to high-volume ice production needs, the EF250 showcases a blend of advanced technologies and user-friendly features that elevate its performance.One of the standout features of the EF250 is its production capability. This model can produce an impressive 242 pounds of ice daily, ensuring that businesses have an ample supply to meet their demands. The unit’s high production rate is complemented by an efficient system that allows for quick recovery times, making it suitable for peak service hours.

The EF250 employs a durable construction with stainless steel housing, ensuring longevity and resistance to corrosion. The robust build quality is designed to withstand the rigors of commercial use, contributing to lower maintenance costs over time. Additionally, the ice maker features a dual-compartment design that enhances ice production while streamlining the storage process.

Another key technological feature of the Ice-O-Matic EF250 is its advanced airflow system, which optimizes heat exchange efficiency. This not only helps to maintain consistent ice production rates but also contributes to lower energy consumption. The EF250 is engineered to operate quietly, minimizing noise disruptions in busy environments while still delivering high performance.

The unit also includes a smart digital control panel that makes operation straightforward. This intuitive interface allows users to monitor ice production levels, troubleshoot issues, and schedule maintenance alerts, ensuring that the machine runs smoothly at all times. The built-in cleaning cycle further simplifies maintenance, promoting hygiene and ice quality.

In summary, the Ice-O-Matic EF250 stands out in the crowded ice machine market due to its high production capabilities, durable build, and advanced technology. Designed for efficiency and ease of use, this ice maker is a reliable choice for any establishment reliant on consistent ice supply, providing both quality and performance for demanding commercial environments.