PC 640 X/HA, PC 640 T X/HA, PC 640 T /HA, PC 640/HA specifications

The Indesit PC 640 series, including the PC 640/HA, PC 640 T/HA, PC 640 T X/HA, and PC 640 X/HA, represents a versatile range of built-in gas hobs designed to cater to various cooking needs. These models are particularly known for their sleek aesthetics and functional features, making them a popular choice for modern kitchens.One of the standout features of the Indesit PC 640 series is its gas burners, which provide efficient heat management and precise temperature control. The series typically includes multiple burners of varying sizes, allowing users to cook multiple dishes simultaneously at different heat levels. The robust construction of the burners ensures durability and reliability, essential for everyday cooking.

Safety is a paramount consideration in the design of the Indesit PC 640 models. Each hob is equipped with flame failure devices that automatically cut off the gas supply if a flame goes out, preventing potential hazards. This feature is particularly important for families with children or for those who prioritize kitchen safety.

In terms of aesthetics, the PC 640 series boasts a stylish design that seamlessly blends into any kitchen decor. The glass or stainless steel surfaces are not only visually appealing but also easy to clean. The control knobs are thoughtfully placed for easy access, ensuring the user can adjust settings without difficulties.

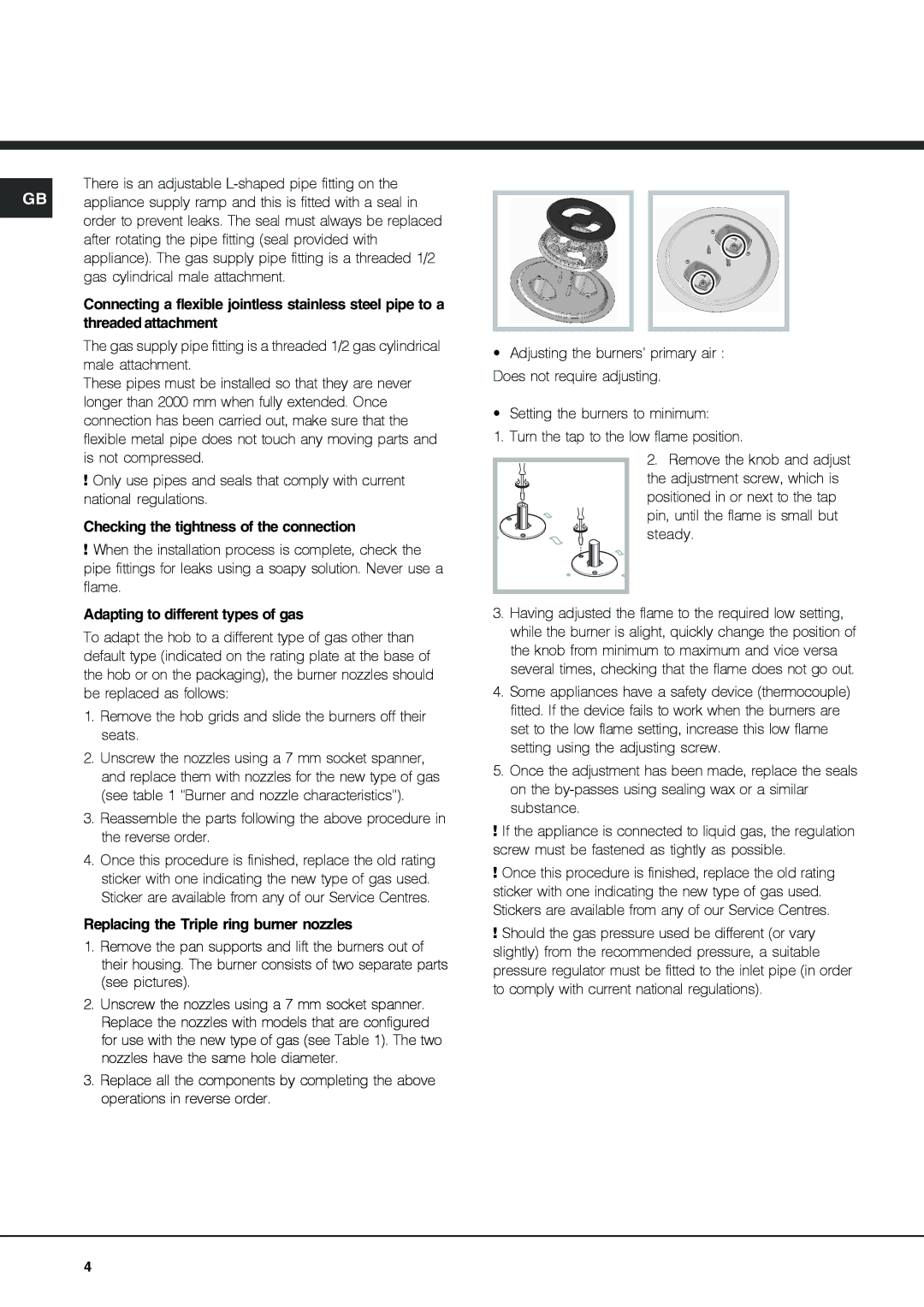

The Indesit PC 640 T series includes the added advantage of a trivets system, which allows for various pot sizes and shapes, enhancing cooking versatility. The hobs are designed to accommodate a range of cookware, including woks and large pots, making them ideal for diverse culinary practices.

Another key characteristic of these models is their energy efficiency. The gas burners are engineered to deliver maximum heat output with minimal gas usage, making them an economical choice for cooking. This not only saves on energy bills but also promotes a more environmentally friendly cooking approach.

Innovation in the PC 640 series is further highlighted by its compatibility with automatic ignition systems, which provide quick and easy ignition of burners with just a simple turn of the knob. This feature enhances user convenience and eliminates the need for matches or lighters.

In summary, the Indesit PC 640 series, comprising models like the PC 640/HA, PC 640 T/HA, PC 640 T X/HA, and PC 640 X/HA, combines functionality, safety, and modern design. With their efficient cooking capabilities, safety features, and user-friendly design, these hobs are well-suited for both novice cooks and seasoned chefs alike, making them a valuable addition to any kitchen.