English

CAUTION

Delay the feed speed when cutting the material into small circular arcs. An unreasonably fast feed may break the blade.

4.Plunge cutting

With this tool, you can perform plunge cutting on plywood panels and thin board materials. You can carry out pocket cutting quite easily with the saw blade installed in reverse as illustrated in Fig. 22, Fig. 24, and Fig. 26. Use the saw blade that is as short and thick as possible. We recommend for this purpose that you use

(1)Press the lower part (or the upper part) of the base against the material. Pull the switch trigger while keeping the tip of the saw blade apart from the material (Fig. 21, Fig. 22).

(2)Raise the handle slowly and cut in with the saw blade little by little (Fig. 23, Fig. 24).

(3)Hold the body firmly until the saw blade completely cuts into the material (Fig. 25, Fig. 26).

CAUTION

◯Avoid plunge cutting for metallic materials. This can easily damage the blade.

◯Never pull the switch trigger while the tip of the saw blade tip is pressed against the material. If you do so, the blade can easily be damaged when it collides with the material.

◯Make absolutely sure that you cut slowly while holding the body firmly. If you apply any

unreasonable force to the saw blade during the cutting operation, the blade can easily be damaged.

5. Cut off guide for cutting pipe (optional accessory)

Product | Cutting | Blade | Code No. | |

application | used | |||

|

| |||

|

|

|

| |

Outer diameter | No. 9 | 321113 | ||

guide (L) | 75mm – 165mm | No. 131 | ||

|

NOTE

Please refer to the cut off guide user’s manual for details on how to use ti correctly.

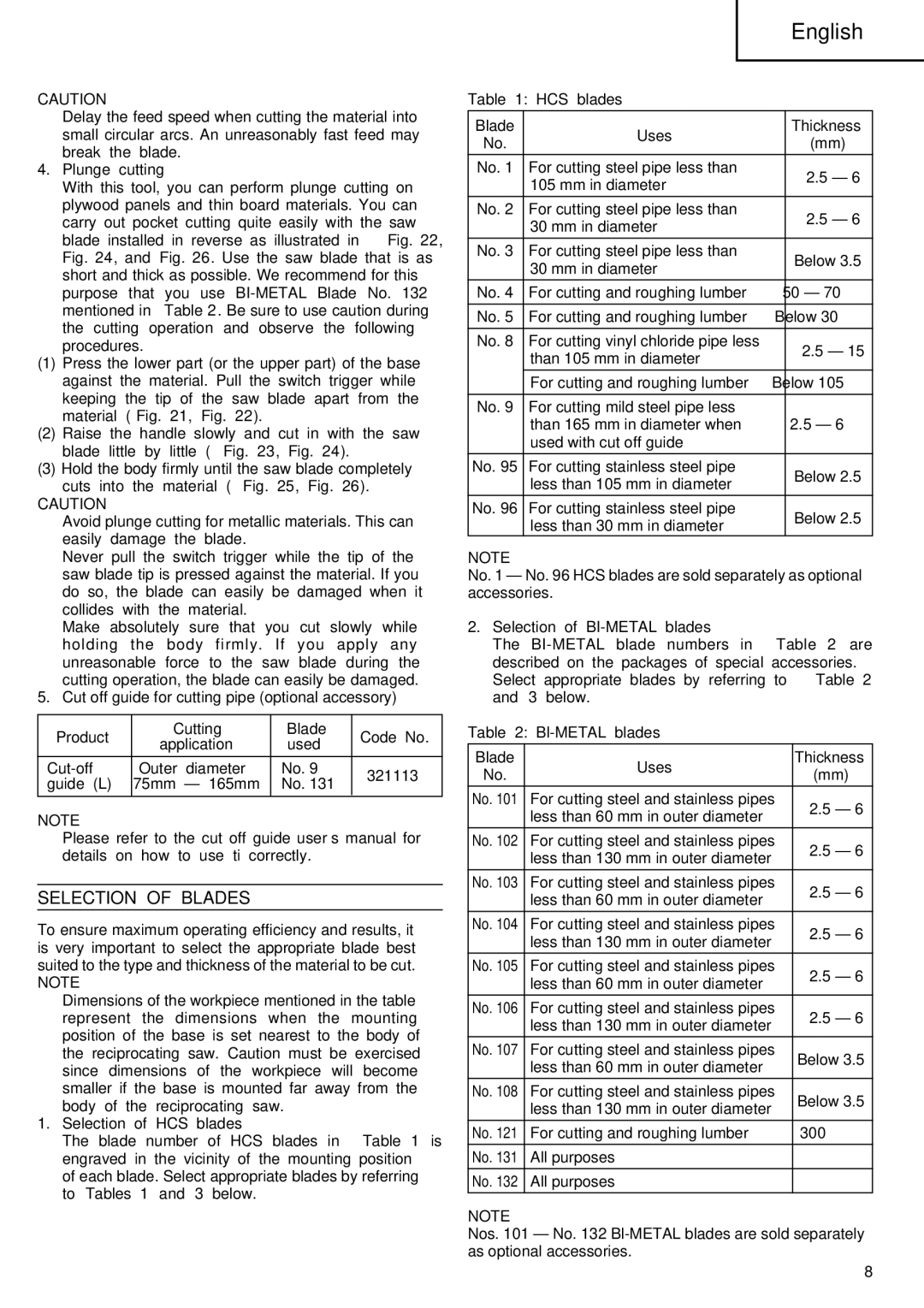

SELECTION OF BLADES

To ensure maximum operating efficiency and results, it is very important to select the appropriate blade best suited to the type and thickness of the material to be cut.

NOTE

◯Dimensions of the workpiece mentioned in the table represent the dimensions when the mounting position of the base is set nearest to the body of the reciprocating saw. Caution must be exercised

since dimensions of the workpiece will become smaller if the base is mounted far away from the body of the reciprocating saw.

1.Selection of HCS blades

The blade number of HCS blades in Table 1 is engraved in the vicinity of the mounting position of each blade. Select appropriate blades by referring to Tables 1 and 3 below.

Table 1: HCS blades

Blade | Uses | Thickness | |

No. | (mm) | ||

| |||

No. 1 | For cutting steel pipe less than | 2.5 – 6 | |

| 105 mm in diameter | ||

|

| ||

No. 2 | For cutting steel pipe less than | 2.5 – 6 | |

| 30 mm in diameter | ||

|

| ||

No. 3 | For cutting steel pipe less than | Below 3.5 | |

| 30 mm in diameter | ||

|

| ||

No. 4 | For cutting and roughing lumber | 50 – 70 | |

No. 5 | For cutting and roughing lumber | Below 30 | |

No. 8 | For cutting vinyl chloride pipe less | 2.5 – 15 | |

| than 105 mm in diameter | ||

|

| ||

| For cutting and roughing lumber | Below 105 | |

No. 9 | For cutting mild steel pipe less |

| |

| than 165 mm in diameter when | 2.5 – 6 | |

| used with cut off guide |

| |

No. 95 | For cutting stainless steel pipe | Below 2.5 | |

| less than 105 mm in diameter | ||

|

| ||

No. 96 | For cutting stainless steel pipe | Below 2.5 | |

| less than 30 mm in diameter | ||

|

|

NOTE

No. 1 – No. 96 HCS blades are sold separately as optional accessories.

2.Selection of BI-METAL blades

The

Table 2: Bl-METAL blades

Blade | Uses | Thickness | |

No. | (mm) | ||

| |||

No. 101 | For cutting steel and stainless pipes | 2.5 – 6 | |

| less than 60 mm in outer diameter | ||

|

| ||

No. 102 | For cutting steel and stainless pipes | 2.5 – 6 | |

| less than 130 mm in outer diameter | ||

|

| ||

No. 103 | For cutting steel and stainless pipes | 2.5 – 6 | |

| less than 60 mm in outer diameter | ||

|

| ||

No. 104 | For cutting steel and stainless pipes | 2.5 – 6 | |

| less than 130 mm in outer diameter | ||

|

| ||

No. 105 | For cutting steel and stainless pipes | 2.5 – 6 | |

| less than 60 mm in outer diameter | ||

|

| ||

No. 106 | For cutting steel and stainless pipes | 2.5 – 6 | |

| less than 130 mm in outer diameter | ||

|

| ||

No. 107 | For cutting steel and stainless pipes | Below 3.5 | |

| less than 60 mm in outer diameter |

| |

No. 108 | For cutting steel and stainless pipes | Below 3.5 | |

| less than 130 mm in outer diameter | ||

No. 121 | For cutting and roughing lumber | 300 | |

No. 131 | All purposes | — | |

No. 132 | All purposes | — |

NOTE

Nos. 101 – No. 132

8