PLACING TOOL IN SERVICE

LUBRICATION

Ingersoll-Rand No. 10

Always use an air line lubricator with these tools.

We recommend the following

For USA - No.

Before operating the tool and after each two to three hours of operation, unless an air line lubricator is used, detach the air hose and inject several drops of

When the tool is to be idle for a period exceeding 24 hours, lubricate it in the regular manner and operate it for 5 seconds. This will coat the internal parts with oil and prevent rusting while the tool is idle.

Never use a heavy oil or oil that forms a gum.

If the action of the tool becomes sluggish, in a well ventilated area, remove the air hose, pour about one teaspoonful of a clean, suitable cleaning solution into the air inlet and operate the tool for not more than thirty

seconds. Immediately, follow this treatment with an injection of

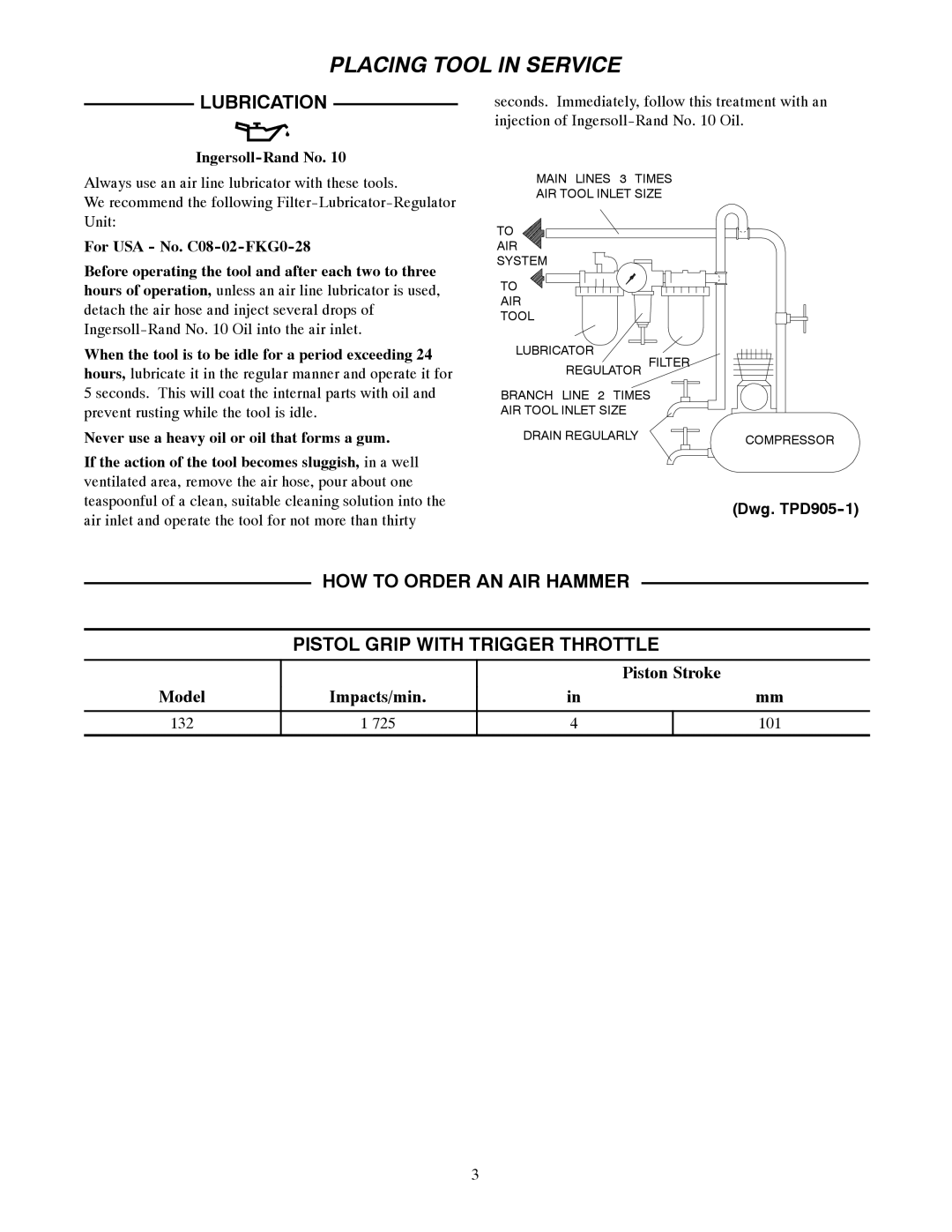

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR FILTER

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY | COMPRESSOR |

|

(Dwg.

HOW TO ORDER AN AIR HAMMER

PISTOL GRIP WITH TRIGGER THROTTLE

|

|

| Piston Stroke | |

Model | Impacts/min. | in |

| mm |

|

|

|

| |

132 | 1 725 | 4 |

| 101 |

3