EN

Product Safety Information

Intended Use:

These Sanders are designed for sanding, feather edging and surface preparing.

For additional information refer to Safety Information Manual Form 04580387. Manuals can be downloaded from www.irtools.com.

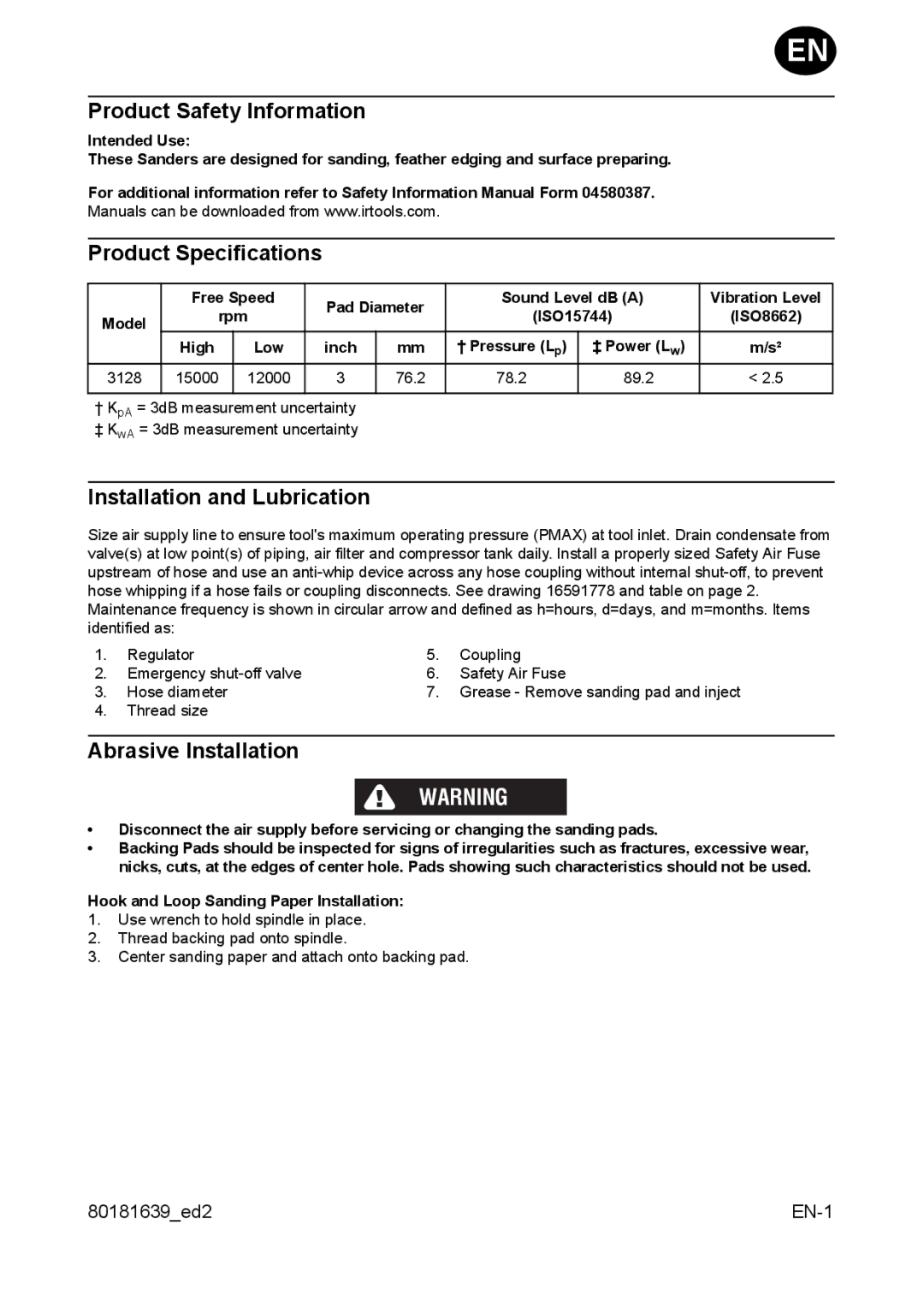

Product Specifications

| Free Speed | Pad Diameter | Sound Level dB (A) | Vibration Level | ||||

Model |

| rpm | (ISO15744) | (ISO8662) | ||||

|

|

| ||||||

| High |

| Low | inch | mm | † Pressure (Lp) | ‡ Power (Lw) | m/s² |

3128 | 15000 |

| 12000 | 3 | 76.2 | 78.2 | 89.2 | < 2.5 |

|

|

|

|

|

|

|

|

|

†KpA = 3dB measurement uncertainty

‡ KwA = 3dB measurement uncertainty

Installation and Lubrication

Size air supply line to ensure tool's maximum operating pressure (PMAX) at tool inlet. Drain condensate from valve(s) at low point(s) of piping, air filter and compressor tank daily. Install a properly sized Safety Air Fuse upstream of hose and use an

1. | Regulator | 5. | Coupling |

2. | Emergency | 6. | Safety Air Fuse |

3. | Hose diameter | 7. | Grease - Remove sanding pad and inject |

4.Thread size

Abrasive Installation

WARNING

•Disconnect the air supply before servicing or changing the sanding pads.

•Backing Pads should be inspected for signs of irregularities such as fractures, excessive wear, nicks, cuts, at the edges of center hole. Pads showing such characteristics should not be used.

Hook and Loop Sanding Paper Installation:

1.Use wrench to hold spindle in place.

2.Thread backing pad onto spindle.

3.Center sanding paper and attach onto backing pad.

80181639_ed2 |