OPERATOR’S MANUAL |

|

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

STAINLESS STEEL FLUID HEATER

RELEASED:

REVISED:

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

FLUID HEATER DATA

Models | |

Wetted Parts Material | Stainless Steel |

Volts AC | 220 |

Amperes | 8.3 |

Watts | 2000 |

Accuracy | ±1.9_ C |

Temperature Rise Above Ambient . . . | 38_ C (100_ F) |

Recovery Rate per Hour | 56.8 liters (15 gallons) |

Maximum Working Pressure | 35 MPa (5000 p.s.i.) |

Maximum Temperature Range | 16 - 121_ C (60 - 250_ F) |

Surface Temperature Code | T3 (200_ C / 392_ F) |

Fluid Passage Diameter | 9.4 mm (0.370”) |

Fluid Passage Length | 232.9 cm (91.7”) |

Fluid Passage Volume | 0.162 lit. (9.86 in.3) |

Inlet / Outlet Port Size (female) | 1/2 - 14 N.P.T.F. - 1 |

Weight | 8.2 kg (18 lbs) |

Environment Approval | Group II 2 G Ex dII B T3 |

CENELEC Standard | EN |

Notified Body Certification | TRL04ATEX11052 |

GENERAL DESCRIPTION

The Aro stainless steel fluid heater models are wired for 220 volt AC ap- plications. The heating element is a 2000 watt cartridge type and is ther- mostatically controlled. The wiring, heating element and thermostat are protected by a preset heat limiter.

The thermostat is adjustable up to approximately 121_ C (250_ F). The heater is off when the thermostat knob is turned counterclockwise as far as possible. The heater will not switch on until the knob is rotated to at least ambient room temperature.

Fluid heaters have been tested in water soluble oil. Some of this fluid may be left within the heater, therefore flush out this fluid with a solvent compatible with the material to be pumped.

•This unit utilizes an

•Two or more paint heaters may be coupled together by plumbing the material outlet of the first heater to the material inlet of the next, etc. However, the distance of piping run between the units should be lim- ited to no more than three feet (see figure 4, page 4).

TYPICAL INSTALLATION

The heater inlet and outlet should be plumbed (up flow) as shown (see figure 4, page 4), to minimize chances of trapped air inside the heater. If the inlet and outlet are reversed (down flow), the temperature rise will be different.

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) | © 2010 | CCN 15200561 |

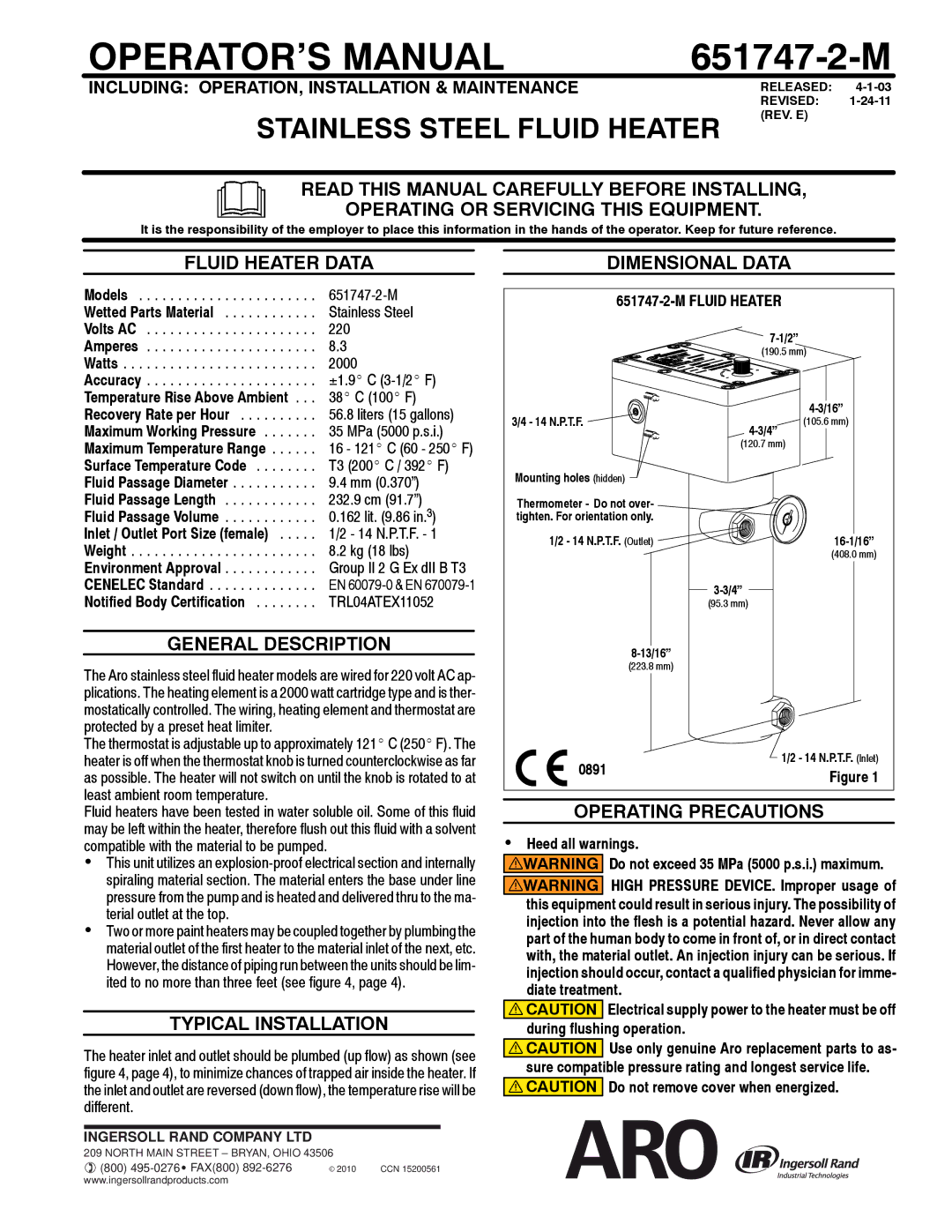

DIMENSIONAL DATA

|

| |

|

| |

| (190.5 mm) | |

3/4 - 14 N.P.T.F. |

| |

(105.6 mm) | ||

|

| |

| (120.7 mm) |

|

Mounting holes (hidden) |

|

|

Thermometer - Do not over- |

|

|

tighten. For orientation only. |

|

|

1/2 - 14 N.P.T.F. (Outlet) |

| |

|

| (408.0 mm) |

|

| |

| (95.3 mm) |

|

|

| |

(223.8 mm) |

|

|

0891 | 1/2 - 14 N.P.T.F. (Inlet) | |

| Figure 1 | |

|

| |

OPERATING PRECAUTIONS

•Heed all warnings.

![]()

![]() WARNING Do not exceed 35 MPa (5000 p.s.i.) maximum.

WARNING Do not exceed 35 MPa (5000 p.s.i.) maximum. ![]() WARNING HIGH PRESSURE DEVICE. Improper usage of

WARNING HIGH PRESSURE DEVICE. Improper usage of

this equipment could result in serious injury. The possibility of injection into the flesh is a potential hazard. Never allow any part of the human body to come in front of, or in direct contact with, the material outlet. An injection injury can be serious. If injection should occur, contact a qualified physician for imme- diate treatment.

![]() CAUTION Electrical supply power to the heater must be off

CAUTION Electrical supply power to the heater must be off

during flushing operation.

![]() CAUTION Use only genuine Aro replacement parts to as-

CAUTION Use only genuine Aro replacement parts to as-

sure compatible pressure rating and longest service life. ![]()

![]() CAUTION Do not remove cover when energized.

CAUTION Do not remove cover when energized.

www.ingersollrandproducts.com