|

| PART NUMBER | FOR ORDERING | t. |

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

| t | |

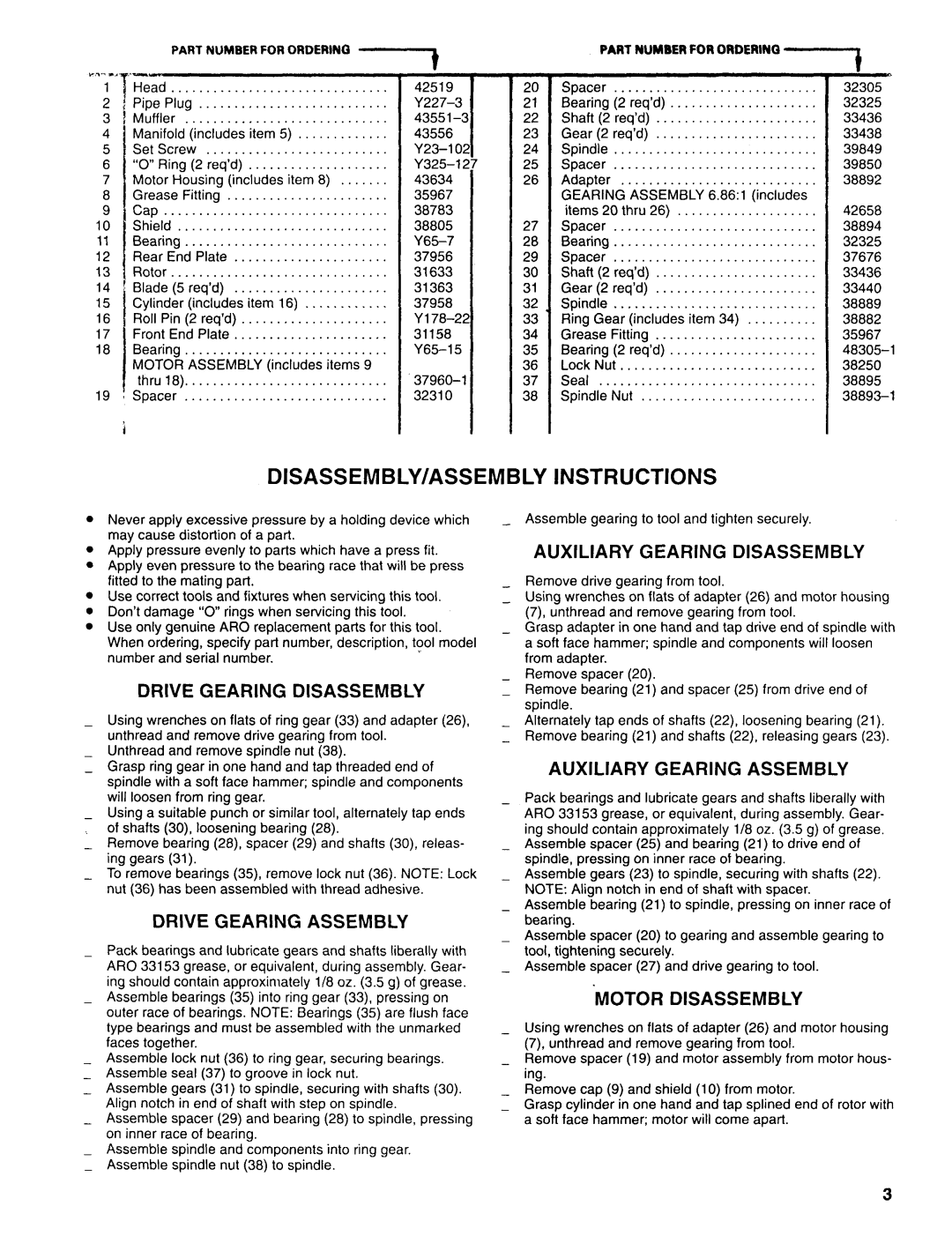

1 | Head | ............................... |

|

|

|

| 42519 | 20 | Spacer | ............................. | 32305 | |||

2 | Pipe | Plug |

|

|

| 21 | Bearing | (2 req’d) | 32325 | |||||

3 | Muffler | ............................. |

|

|

| 22 | Shaft | (2 req’d) | 33436 | |||||

4 | Manifold | (includes | item | 5) | 43556 | 23 | Gear | (2 req’d) | 33438 | |||||

5 | Set Screw |

|

|

| 24 | Spindle | ............................. | 39849 | ||||||

6 | “0” Ring | (2 req’d) | .................... |

|

| 25 | Spacer | ............................. | 39850 | |||||

7 | Motor | Housing (includes | item | 8) | 43634 | 26 | Adapter |

| ............................ | 38892 | ||||

8 | Grease | Fitting |

|

|

| 35967 |

| GEARING | ASSEMBLY 6.86:l | (includes | ||||

9 | Cap |

|

| 38783 |

| items |

| 20 | thru 26) | 42658 | ||||

10 | Shield |

|

|

|

| 38805 | 27 | Spacer | ............................. | 38894 | ||||

11 | Bearing | ............................. |

|

|

| 28 | Bearing | 32325 | ||||||

12 | Rear | End Plate |

|

|

| 37956 | 29 | Spacer | ............................. | 37676 | ||||

13 | Rotor | ............................... |

|

|

|

| 31633 | 30 | Shaft | (2 req’d) | 33436 | |||

14 | Blade | (5 req’d) |

|

|

| 31363 | 31 | Gear | (2 req’d) | 33440 | ||||

15 | Cylinder | (includes | item | 16) | 37958 | 32 | Spindle | ............................. | 38889 | |||||

16 | Roll Pin | (2 req’d) |

|

|

| 33 | Ring | Gear | (includes item 34) | .......... 38882 | ||||

17 | Front | End Plate |

|

|

| 31158 | 34 | Grease | Fitting | 35967 | ||||

18 | Bearing | ............................. |

|

|

| 35 | Bearing | (2 req’d) | ||||||

| MOTOR | ASSEMBLY | (includes | items 9 | 36 | Lock Nut | 38250 | |||||||

| thru 18) | ............................. |

|

|

| 37 | Seal | ............................... |

| 38895 | ||||

19 | Spacer | ............................. |

|

|

| 32310 | 38 | Spindle | Nut | |||||

DISASSEMBLY/ASSEMBLY INSTRUCTIONS

lNever apply excessive pressure by a holding device which may cause distortion of a part.

lApply pressure evenly to parts which have a press fit.

lApply even pressure to the bearing race that will be press fitted to the mating part.

lUse correct tools and fixtures when servicing this tool. l Don’t damage “0” rings when servicing this tool.

l Use only genuine ARO replacement parts for this tool. When ordering, specify part number, description, tool model number and serial number.

DRIVE GEARING DISASSEMBLY

-Using wrenches on flats of ring gear (33) and adapter (26), unthread and remove drive gearing from tool.

-Unthread and remove spindle nut (38).

-Grasp ring gear in one hand and tap threaded end of spindle with a soft face hammer; spindle and components will loosen from ring gear.

-Using a suitable punch or similar tool, alternately tap ends

., of shafts (30), loosening bearing (28).

-Remove bearing (28), spacer (29) and shafts (30), releas- ing gears (31).

-To remove bearings (35), remove lock nut (36). NOTE: Lock nut (36) has been assembled with thread adhesive.

DRIVE GEARING ASSEMBLY

-Pack bearings and lubricate gears and shafts liberally with ARO 33153 grease, or equivalent, during assembly. Gear- ing should contain approximately 1/8 oz. (3.5 g) of grease.

-Assemble bearings (35) into ring gear (33), pressing on outer race of bearings. NOTE: Bearings (35) are flush face type bearings and must be assembled with the unmarked faces together.

-Assemble lock nut (36) to ring gear, securing bearings.

-Assemble seal (37) to groove in lock nut.

-Assemble gears (31) to spindle, securing with shafts (30). Align notch in end of shaft with step on spindle.

-Assemble spacer (29) and bearing (28) to spindle, pressing on inner race of bearing.

-Assemble spindle and components into ring gear.

-Assemble spindle nut (38) to spindle.

Assemble gearing to tool and tighten securely.

AUXILIARY GEARING DISASSEMBLY

Remove drive gearing from tool.

Using wrenches on flats of adapter (26) and motor housing (7), unthread and remove gearing from tool.

Grasp adapter in one hand and tap drive end of spindle with a soft face hammer; spindle and components will loosen from adapter.

Remove spacer (20).

-Remove bearing (21) and spacer (25) from drive end of spindle.

-Alternately tap ends of shafts (22), loosening bearing (21).

-Remove bearing (21) and shafts (22), releasing gears (23).

AUXILIARY GEARING ASSEMBLY

-Pack bearings and lubricate gears and shafts liberally with ARO 33153 grease, or equivalent, during assembly. Gear- ing should contain approximately 1/8 oz. (3.5 g) of grease.

-Assemble spacer (25) and bearing (21) to drive end of spindle, pressing on inner race of bearing.

-Assemble gears (23) to spindle, securing with shafts (22). NOTE: Align notch in end of shaft with spacer.

-Assemble bearing (21) to spindle, pressing on inner race of bearing.

-Assemble spacer (20) to gearing and assemble gearing to tool, tightening securely.

-Assemble spacer (27) and drive gearing to tool.

MOTOR DISASSEMBLY

-Using wrenches on flats of adapter (26) and motor housing (7), unthread and remove gearing from tool.

-Remove spacer (19) and motor assembly from motor hous- ing.

-Remove cap (9) and shield (10) from motor.

-Grasp cylinder in one hand and tap splined end of rotor with a soft face hammer; motor will come apart.

3