DISASSEMBLY/ASSEMBLY INSTRUCTIONS

MOTOR ASSEMBLY

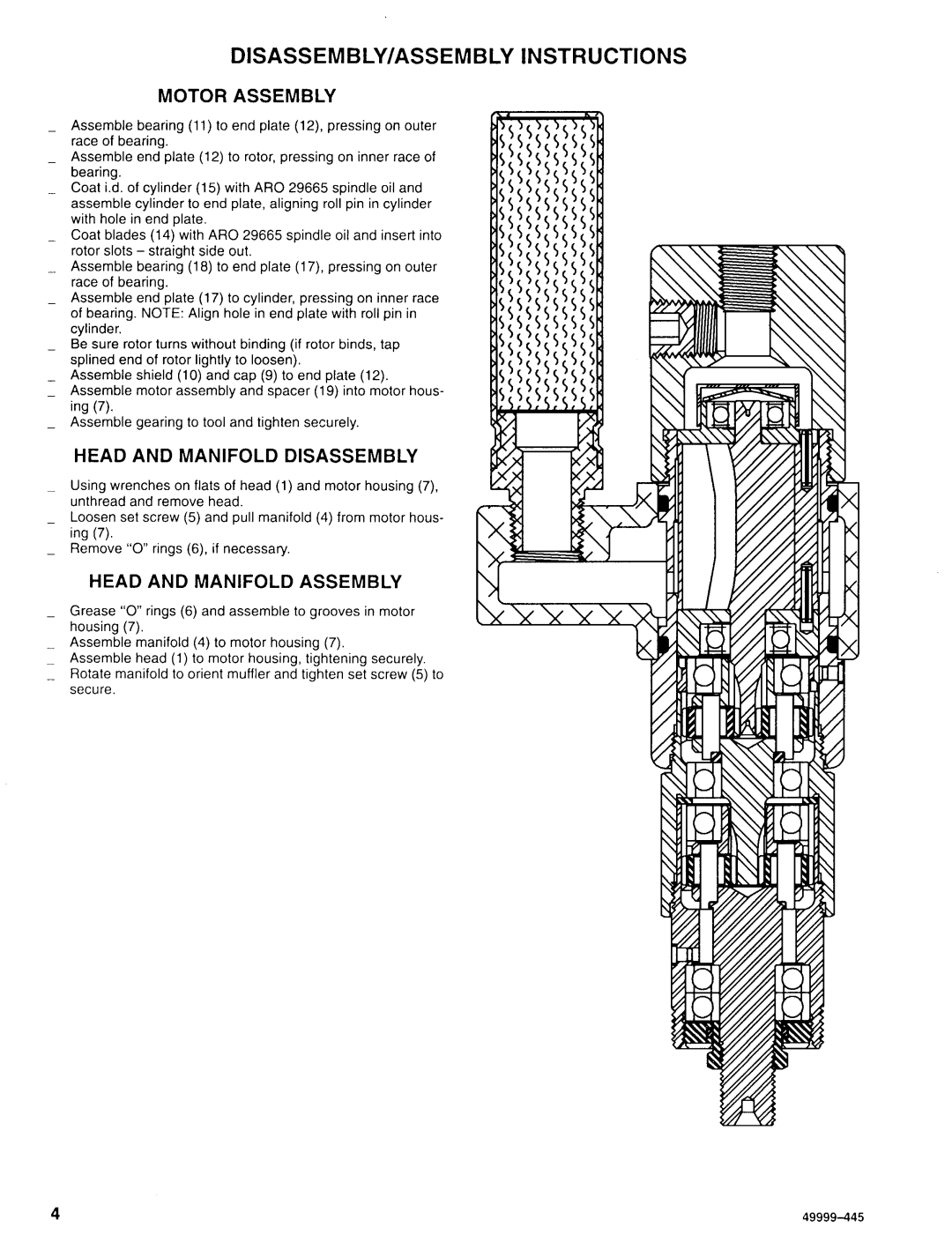

Assemble bearing (11) to end plate (12), pressing on outer race of bearing.

Assemble end plate (12) to rotor, pressing on inner race of bearing.

Coat i.d. of cylinder (15) with ARO 29665 spindle oil and assemble cylinder to end plate, aligning roll pin in cylinder with hole in end plate.

Coat blades (14) with ARO 29665 spindle oil and insert into rotor slots - straight side out.

Assemble bearing (18) to end plate (17), pressing on outer race of bearing.

Assemble end plate (17) to cylinder, pressing on inner race of bearing. NOTE: Align hole in end plate with roll pin in cylinder.

Be sure rotor turns without binding (if rotor binds, tap splined end of rotor lightly to loosen).

Assemble shield (10) and cap (9) to end plate (12). Assemble motor assembly and spacer (19) into motor hous- ing (7).

Assemble gearing to tool and tighten securely.

HEAD AND MANIFOLD DISASSEMBLY

Using wrenches on flats of head (1) and motor housing (7), unthread and remove head.

Loosen set screw (5) and pull manifold (4) from motor hous- ing (7).

Remove “0” rings (6), if necessary.

HEAD AND MANIFOLD ASSEMBLY

Grease “0” rings (6) and assemble to grooves in motor housing (7).

Assemble manifold (4) to motor housing (7).

Assemble head (1) to motor housing, tightening securely. Rotate manifold to orient muffler and tighten set screw (5) to secure.