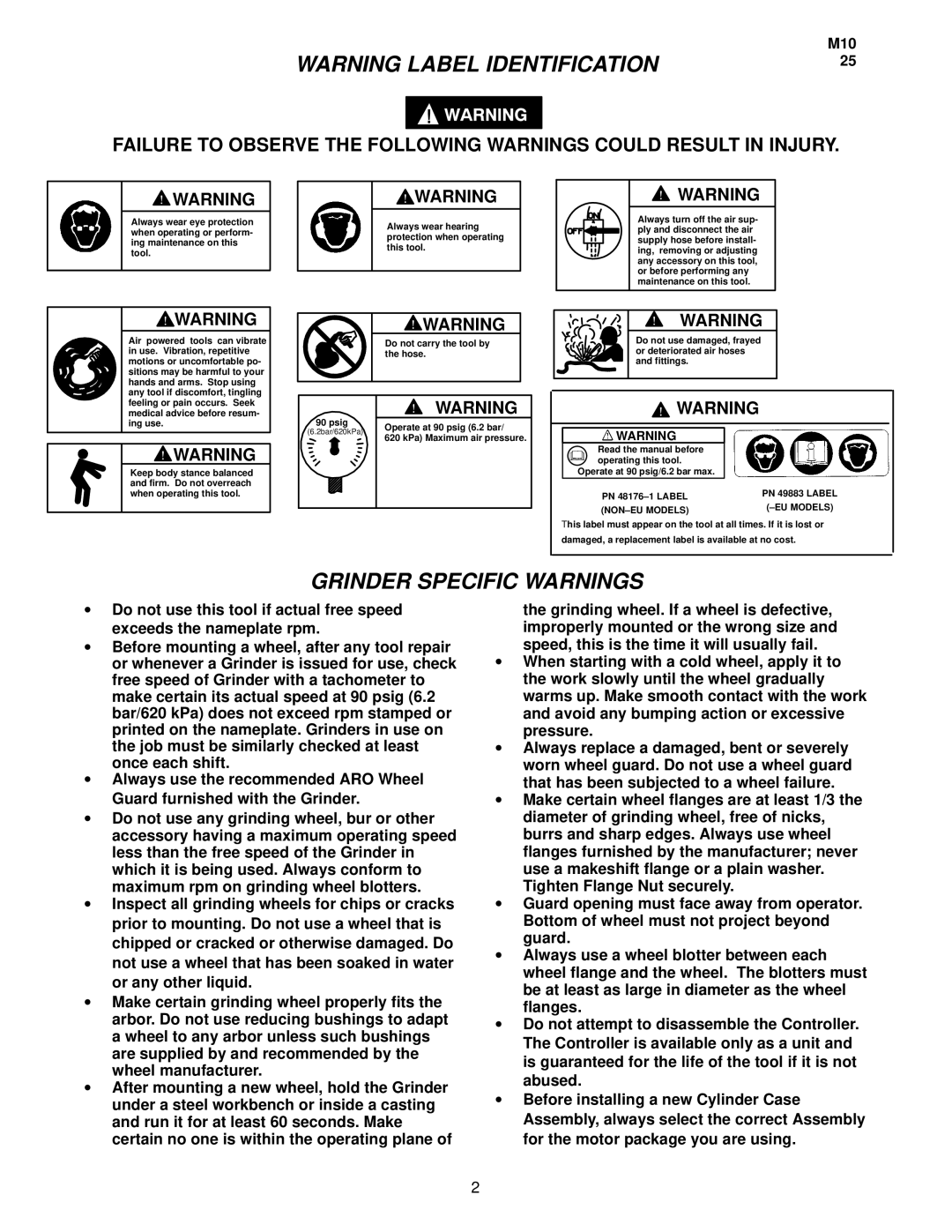

WARNING LABEL IDENTIFICATION

M10

25

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

![]() WARNING

WARNING

Always wear eye protection when operating or perform- ing maintenance on this tool.

![]() WARNING

WARNING

Always wear hearing protection when operating this tool.

![]() WARNING

WARNING

Always turn off the air sup- ply and disconnect the air supply hose before install- ing, removing or adjusting any accessory on this tool, or before performing any maintenance on this tool.

![]() WARNING

WARNING

Air powered tools can vibrate in use. Vibration, repetitive motions or uncomfortable po- sitions may be harmful to your hands and arms. Stop using any tool if discomfort, tingling feeling or pain occurs. Seek medical advice before resum- ing use.

![]() WARNING

WARNING

Keep body stance balanced and firm. Do not overreach when operating this tool.

| WARNING | |

| Do not carry the tool by | |

| the hose. | |

90 psig | WARNING | |

Operate at 90 psig (6.2 bar/ | ||

(6.2bar/620kPa) | ||

620 kPa) Maximum air pressure. | ||

|

WARNING

Do not use damaged, frayed or deteriorated air hoses and fittings.

![]() WARNING

WARNING

WARNING |

|

Read the manual before |

|

operating this tool. |

|

Operate at 90 psig/6.2 bar max. |

|

PN | PN 49883 LABEL |

|

| |

|

This label must appear on the tool at all times. If it is lost or

damaged, a replacement label is available at no cost.

GRINDER SPECIFIC WARNINGS

•Do not use this tool if actual free speed exceeds the nameplate rpm.

•Before mounting a wheel, after any tool repair or whenever a Grinder is issued for use, check free speed of Grinder with a tachometer to make certain its actual speed at 90 psig (6.2 bar/620 kPa) does not exceed rpm stamped or printed on the nameplate. Grinders in use on the job must be similarly checked at least once each shift.

•Always use the recommended ARO Wheel Guard furnished with the Grinder.

•Do not use any grinding wheel, bur or other accessory having a maximum operating speed less than the free speed of the Grinder in which it is being used. Always conform to maximum rpm on grinding wheel blotters.

•Inspect all grinding wheels for chips or cracks prior to mounting. Do not use a wheel that is chipped or cracked or otherwise damaged. Do not use a wheel that has been soaked in water or any other liquid.

•Make certain grinding wheel properly fits the arbor. Do not use reducing bushings to adapt a wheel to any arbor unless such bushings are supplied by and recommended by the wheel manufacturer.

•After mounting a new wheel, hold the Grinder under a steel workbench or inside a casting and run it for at least 60 seconds. Make certain no one is within the operating plane of

the grinding wheel. If a wheel is defective, improperly mounted or the wrong size and speed, this is the time it will usually fail.

•When starting with a cold wheel, apply it to the work slowly until the wheel gradually warms up. Make smooth contact with the work and avoid any bumping action or excessive pressure.

•Always replace a damaged, bent or severely worn wheel guard. Do not use a wheel guard that has been subjected to a wheel failure.

•Make certain wheel flanges are at least 1/3 the diameter of grinding wheel, free of nicks, burrs and sharp edges. Always use wheel flanges furnished by the manufacturer; never use a makeshift flange or a plain washer. Tighten Flange Nut securely.

•Guard opening must face away from operator. Bottom of wheel must not project beyond guard.

•Always use a wheel blotter between each wheel flange and the wheel. The blotters must be at least as large in diameter as the wheel flanges.

•Do not attempt to disassemble the Controller. The Controller is available only as a unit and is guaranteed for the life of the tool if it is not abused.

•Before installing a new Cylinder Case Assembly, always select the correct Assembly for the motor package you are using.

2