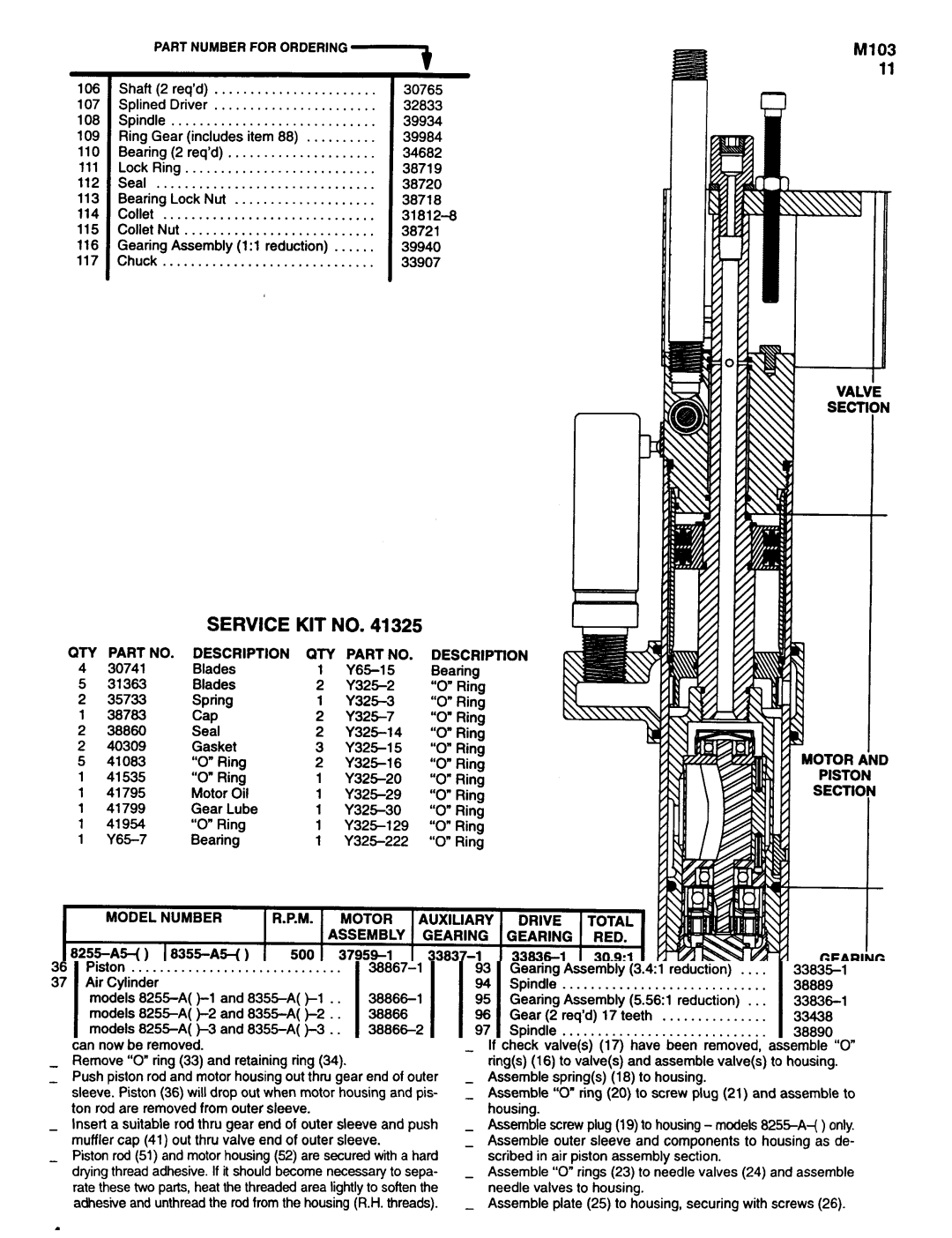

8355A, 8255-A specifications

Ingersoll-Rand is a renowned name in the field of industrial manufacturing, particularly known for its production of air compressors and related equipment. Among its notable offerings are the Ingersoll-Rand 8255-A and 8355A pneumatic compressors, which exemplify robust engineering and cutting-edge technology. These models are tailored for demanding applications, providing the reliability and performance that professionals in various industries require.One of the standout features of the Ingersoll-Rand 8255-A and 8355A is their powerful performance capability. Both models are designed to deliver a high CFM (Cubic Feet per Minute) output, ensuring adequate airflow for even the most demanding tools and pneumatic devices. This makes them suitable for a range of applications, from automotive repair and manufacturing processes to construction and heavy-duty maintenance tasks.

The compressors are equipped with advanced rotary screw technology, known for its efficiency and silent operation. This technology enables the compressors to generate compressed air continuously, with less energy consumption than traditional piston compressors. The durability of the rotary screw design reduces wear and tear, leading to longer lifespans and lower maintenance costs.

Another significant feature is the inclusion of a sophisticated control system. This system allows users to monitor and adjust various parameters, such as pressure and temperature, enhancing operational efficiency. Additionally, the user-friendly interface simplifies the task of managing the compressor, ensuring that it can be operated with minimal training.

The 8255-A and 8355A models also prioritize safety and environmental considerations. They come with built-in safety features that prevent overloading and ensure stable operations, protecting both the equipment and the user. Furthermore, their environmentally friendly design aligns with contemporary sustainability goals, making them a responsible choice for modern enterprises.

In terms of mobility, both compressors are designed for ease of transport. They feature rugged frames and wheels, enabling them to be moved easily across job sites. This portability enhances their versatility, allowing for quick relocation as jobs change in scope and location.

In conclusion, the Ingersoll-Rand 8255-A and 8355A compressors stand out because of their powerful performance, innovative technologies, and essential safety features. They represent a blend of reliability and efficiency, making them invaluable assets in a variety of industrial and commercial applications.