LUBRICATION

Where Used | ARO Part # | Description |

Air Motor | 29665 | 1 qt. Spindle Oil |

‘‘O” Rings & Lip Seals | 36460 | 4 oz. Stringy |

|

| Lubricant |

Gears and Bearings | 33153 | 5 lb. ‘‘EP” – NLGI |

|

| #1 Grease |

Always use an air line lubricator with these tools.

M12

15

Do not mark any nonmetallic surface on this tool with customer identification codes. Such actions could affect tool performance.

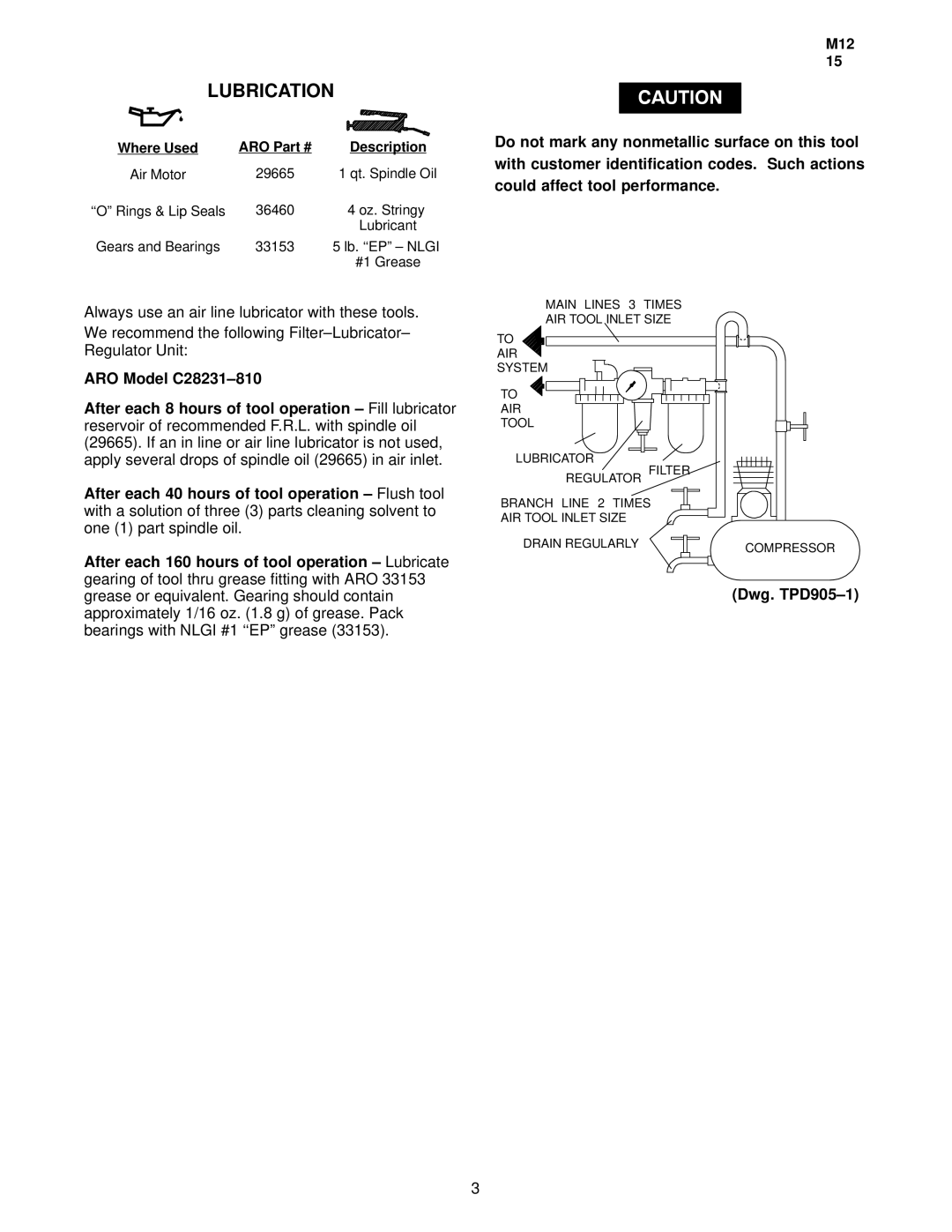

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

We recommend the following

ARO Model

After each 8 hours of tool operation – Fill lubricator reservoir of recommended F.R.L. with spindle oil (29665). If an in line or air line lubricator is not used, apply several drops of spindle oil (29665) in air inlet.

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

FILTER

After each 40 hours of tool operation – Flush tool with a solution of three (3) parts cleaning solvent to one (1) part spindle oil.

After each 160 hours of tool operation – Lubricate gearing of tool thru grease fitting with ARO 33153 grease or equivalent. Gearing should contain approximately 1/16 oz. (1.8 g) of grease. Pack bearings with NLGI #1 ‘‘EP” grease (33153).

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY | COMPRESSOR |

|

(Dwg.

3